Institute for Basic Science "World's Best Performance"

A photocatalytic platform that floats on water surfaces such as seas, lakes, and rivers or on solutions of waste plastic has been developed to produce hydrogen.

The Institute for Basic Science (IBS) announced on the 28th that a joint research team led by Kim Dae-hyung, Deputy Director of the Nanoparticle Research Division (Professor of Chemical and Biological Engineering at Seoul National University), and Hyun Taek-hwan, Director of the division (Distinguished Professor of Chemical and Biological Engineering at Seoul National University), has newly developed a floating photocatalytic platform with world-class green hydrogen production performance.

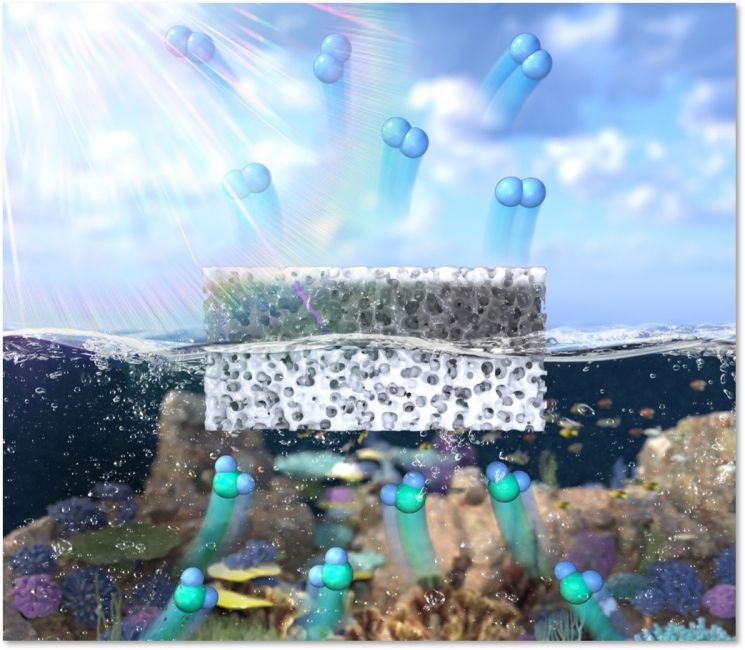

Structure of the floating photocatalyst platform developed by researchers at the Institute for Basic Science (IBS). Photo by IBS

Structure of the floating photocatalyst platform developed by researchers at the Institute for Basic Science (IBS). Photo by IBS

For the commercialization of hydrogen energy, it is essential to develop processes and facilities that can produce hydrogen in an eco-friendly manner with high efficiency. The conventional hydrogen production method, natural gas steam reforming, requires a large amount of energy and emits a significant amount of carbon dioxide (CO2), a greenhouse gas. In contrast, photocatalytic hydrogen production attracts attention because it directly uses solar energy, an infinite energy source, and does not emit greenhouse gases. Photocatalysts absorb solar energy to produce hydrogen (H2) from water (H2O).

Although much research has been conducted to improve photocatalyst performance, commercialization has not yet been achieved. To operate in real environments, powdered photocatalysts need to be fabricated into films or panels, and additional containers to operate them in water and devices to release hydrogen outside the water are required, which significantly reduces the economic feasibility of hydrogen production.

The research team devised a new gel-type photocatalytic platform that floats on water. The new platform has a bilayer structure consisting of an upper photocatalyst layer and a lower support layer. First, the researchers fabricated the photocatalyst in the form of a cryoaerogel to reduce the density of the catalyst itself. Cryoaerogel is a solid material filled with gas inside, characterized by its low density. All photocatalysts, including high-performance platinum (Pt)-based catalysts and inexpensive copper (Cu)-based catalysts, can be made into cryoaerogel forms. Additionally, both layers were made into a porous structure with many holes to increase surface tension, allowing it to float better on water.

The resulting ‘hydrogel platform’ operates on the water surface, minimizing the reverse reaction where hydrogen reverts to water, thus reducing product loss. Also, when the catalyst is submerged, the amount of light entering decreases with water depth, but floating on the surface allows efficient use of solar energy without light scattering. Another advantage is that it can be easily fabricated on a large scale.

The research team also verified hydrogen production performance under sunlight. Using a 1㎡ hydrogel catalyst, about 4 liters of hydrogen could be produced per hour (converted value), which is a world-class performance. Furthermore, even after operating for more than two weeks in harsh seawater environments mixed with various microorganisms and suspended solids, there was almost no performance degradation.

Kim Dae-hyung, Deputy Director of the research team, said, “Hydrogen can be produced not only from natural water but also from solutions made by dissolving household waste such as PET bottles,” adding, “This means that the platform proposed by our research team could be an alternative for waste treatment.” Director Hyun Taek-hwan said, “We confirmed the possibility of green hydrogen production in the sea, not limited land areas, and secured world-class production performance,” and added, “It can be applied not only to hydrogen but also to the production of various organic compounds and hydrogen peroxide (H2O2), contributing to the realization of carbon neutrality.”

The research results were published online on the same day in the international journal Nature Nanotechnology (IF 40.523).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

!["The Woman Who Threw Herself into the Water Clutching a Stolen Dior Bag"...A Grotesque Success Story That Shakes the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)