Coatings for recyclable paper cups and lightweight plastic materials that significantly reduce vehicle weight. The domestic chemical industry has introduced various plastic utilization plans for carbon reduction to the global market.

Paper cups and toothpaste packaging using EAA, a high value-added packaging material introduced by SK Geocentric. Until now, paper cups could not be recycled because the plastic film could not be decomposed, but paper cups coated with EAA become recyclable. Photo by Jeong Donghoon

Paper cups and toothpaste packaging using EAA, a high value-added packaging material introduced by SK Geocentric. Until now, paper cups could not be recycled because the plastic film could not be decomposed, but paper cups coated with EAA become recyclable. Photo by Jeong Donghoon

At 'ChinaPlas 2023,' the world's largest plastics exhibition that concluded on the 20th (local time), global chemical companies presented various products and material utilization plans that recycle plastics, once considered the main culprit of environmental destruction, and expand their range of applications.

A representative example is 'EAA (Ethylene Acrylic Acid, a high-value packaging material),' a material that enables the recycling of paper cups. Paper cups are one of the most commonly consumed disposable items in daily life but have not been recyclable. This is because they are coated with a low-density polyethylene (LDPE) coating that prevents water from soaking into the paper cup, and this coating does not decompose well.

The Resource Circulation Economy Society Research Institute estimates that 23 to 26 billion disposable paper cups are consumed annually in Korea. Of these, only about 1.5% are recycled, while most of the rest are incinerated or landfilled.

SK Geocentric's EAA makes recycling paper cups possible. An SK Geocentric official said, "Paper cups are coated with a 20-micron thin film of PE (polyethylene, a heat-resistant plastic material), which does not easily separate during recycling, resulting in a low recycling rate." He explained, "In contrast, EAA can provide the waterproof function of conventional paper cups simply by spraying a 1 to 2-micron thick layer."

Originally developed as an adhesive for packaging materials, EAA is increasingly used in sterilized packs, vacuum packaging for meat, golf balls, and tempered glass. Currently, about three to four global chemical companies, including SK Geocentric and Dow, produce EAA. SK Geocentric owns EAA production plants in the United States and Spain and plans to build two additional plants in China.

Domestic companies showcased lightweight materials that can extend the driving range in response to the rapid growth of electric vehicles. Next-generation materials that maintain strength while reducing vehicle weight are gaining attention for electric vehicles. Reducing the vehicle weight of a car with a curb weight of 1,500 kg by about 10% improves fuel efficiency by 4 to 6%. According to data from the Korea Automotive Technology Institute, new plastic materials that replace metals are being used in various fields such as battery packs and bumpers.

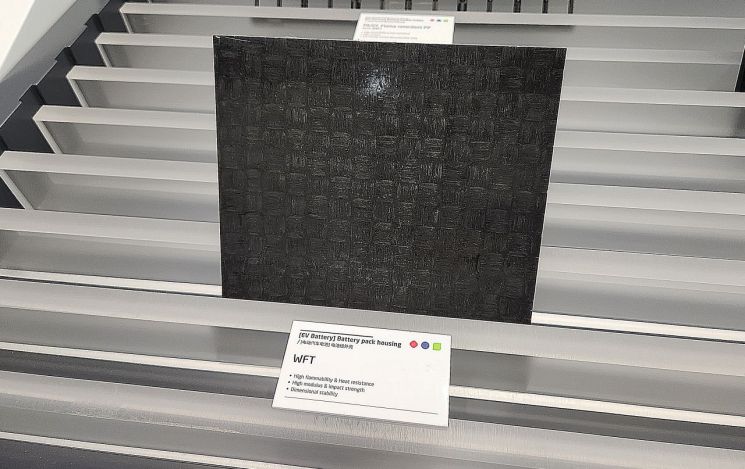

LG Chem exhibited frame materials for electric vehicle battery modules along with carbon nanotubes (CNT). CNT is a new material with electrical and thermal conductivity comparable to copper and diamond and strength 100 times that of steel. It is used as a conductive material that facilitates the flow of electricity and electrons in batteries. Lotte Chemical showcased battery module partitions using thermoplastic polyolefin (TPO) and battery packs using carbon composite fibers. Kolon Plastics introduced a material for electric vehicle battery covers that can withstand flames of 1,200 degrees Celsius for about 10 minutes.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.