Joint Research by KAIST and Hyundai Motor

Extends Lifespan by 30-50%

Domestic researchers have developed an electrolyte additive that can significantly extend the lifespan of silicon-nickel based lithium-ion secondary batteries.

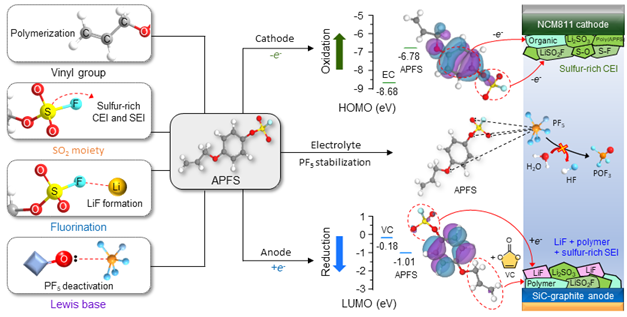

Schematic design of APFS additive protecting high-capacity electrode interfaces. Image source: Provided by KAIST

Schematic design of APFS additive protecting high-capacity electrode interfaces. Image source: Provided by KAIST

KAIST announced on the 19th that a research team led by Namsoon Choi from the Department of Bio and Chemical Engineering, in collaboration with Professor Sangkyu Kwak’s team at Korea University, Professor Seongyu Hong’s team at Ulsan National Institute of Science and Technology (UNIST), Hyundai Motor Company, and the Korea Research Institute of Chemical Technology, has developed an electrolyte additive technology that enables long-term durability at room and high temperatures for lithium-ion secondary batteries composed of high-capacity silicon-based anodes and nickel-rich cathodes.

To realize electric vehicles capable of driving over 500 km on a single charge, the development of high-capacity, high-energy-density secondary batteries is essential. Accordingly, nickel-rich cathodes with high reversible capacity and silicon anode materials exhibiting about ten times the capacity of graphite are attracting attention as materials for next-generation lithium-ion batteries. However, existing electrolyte additive research has shown limitations in responding to new electrode materials because it has been developed through trial and error by screening existing substances, consuming significant time and cost.

The electrolyte additive developed by the research team is a new technology that increases the reversibility of silicon-based anodes and nickel-rich cathodes at low, room, and high temperatures, solving the problem of rapid capacity decline due to increased battery charge-discharge cycles. From the initial design stage of the electrolyte additive, the team successfully designed and synthesized the additive by combining functional groups suitable for the target cathode and anode using molecular engineering techniques. The designed electrolyte additive forms a solid electrolyte interphase on the surfaces of high-capacity silicon-based anodes and nickel-rich cathodes through electrochemical reactions of electron-accepting and electron-donating groups, dramatically improving the battery’s lifespan at room and high temperatures.

The developed technology used silicon-based anodes and nickel-rich cathodes with high composite density at levels required by industry, not just typical laboratory standards. The significance lies in realizing long-term durability of batteries at low, room, and high temperatures and presenting a direction for designing electrolyte additives that maximize efficiency at low cost.

Hyungkyu Moon, a co-first author of the paper and a researcher at KAIST’s Department of Bio and Chemical Engineering, stated, "The developed electrolyte additive forms an electrode interfacial layer with excellent heat resistance and flexibility, enabling the battery composed of silicon-based anodes and nickel-rich cathodes to retain 72.5% of its initial capacity even after 300 repetitive charge-discharge cycles at 45 degrees Celsius, the operating temperature of electric vehicles." He added, "Compared to commonly used additives such as vinylene carbonate (VC) and fluoroethylene carbonate (FEC), the performance improved by 54% and 38%, respectively, effectively suppressing battery degradation caused by volume changes in the silicon anode and showing effectiveness even under dilute electrolyte conditions."

Professor Namsoon Choi said, "This is a world-class electrolyte additive technology that forms an electrode interfacial layer with excellent temperature durability from low to high temperatures under mass production-level electrode loading conditions, and it is expected to be applied to electric vehicle batteries and more."

The research results were published online on the 4th in the international journal Advanced Functional Materials (paper title: Elastic Interfacial Layer Enabled the High-Temperature Performance of Lithium-Ion Batteries via Utilization of Synthetic Fluorosulfate Additive).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.