SNE Research, Next-Generation Battery Technology Seminar on the 12th

Presenters from Both Companies Disagree on All-Solid-State Battery Commercialization Timing

Safe and High Energy Density 'Dream Battery'

All-Solid-State Battery Faces High Technical and Cost Barriers

LG Energy Solution "Difficult by 2030"

Samsung SDI "Mass Production System Ready by 2027"

LG Energy Solution and Samsung SDI showed differing views on the commercialization timeline of the next-generation battery known as the 'all-solid-state battery.' While LG Energy Solution stated that "it will be difficult to commercialize all-solid-state batteries even by 2030," Samsung SDI clearly set a goal to "mass-produce by 2027."

LG Energy Solution: "All-solid-state technology barriers remain high... Commercialization by 2030 is difficult"

Jang Hak-jin, head of the TI (Technology Intelligence) Strategy Team at LG Energy Solution, is explaining the trend of battery price competition and solid-state battery technology. Photo by Jeong Dong-hoon

Jang Hak-jin, head of the TI (Technology Intelligence) Strategy Team at LG Energy Solution, is explaining the trend of battery price competition and solid-state battery technology. Photo by Jeong Dong-hoon

Jang Hak-jin, head of the TI (Technology Intelligence) Strategy Team at LG Energy Solution, said at the 'Next Generation Battery Seminar (NGBS 2023)' held on the 12th at the Korea Science and Technology Center in Yeoksam-dong, Gangnam-gu, Seoul, "All-solid-state batteries are difficult to be price competitive compared to lithium-ion batteries," adding, "Even Japanese companies that have been most actively pursuing all-solid-state battery development are continuously delaying the mass production timeline." He continued, "Next-generation batteries such as all-solid-state batteries will still face difficulties in commercialization by 2030," and "I believe the market will be centered on lithium-ion batteries until 2030."

All-solid-state batteries are considered 'next-generation batteries' due to their safety and high energy density. The liquid or gel-state electrolytes used in conventional lithium-ion batteries expand depending on temperature and can cause fires if electrolyte leakage occurs due to external shocks. In contrast, the solid-state electrolyte in all-solid-state batteries has a lower risk of fire and explosion. Since fewer components such as separators are required, the weight is also lighter. While the energy density of conventional lithium-ion batteries is about 255Wh per kg, all-solid-state batteries theoretically increase energy density up to 495Wh per kg. However, they face challenges across several areas, including ▲expensive solid electrolyte materials ▲shortened battery life due to high resistance at the interface between active materials and solid electrolytes (interfacial resistance) ▲manufacturing processes requiring high temperature and high pressure.

Samsung SDI: "Pilot line to produce all-solid-state battery samples this year... Mass production system ready by 2027"

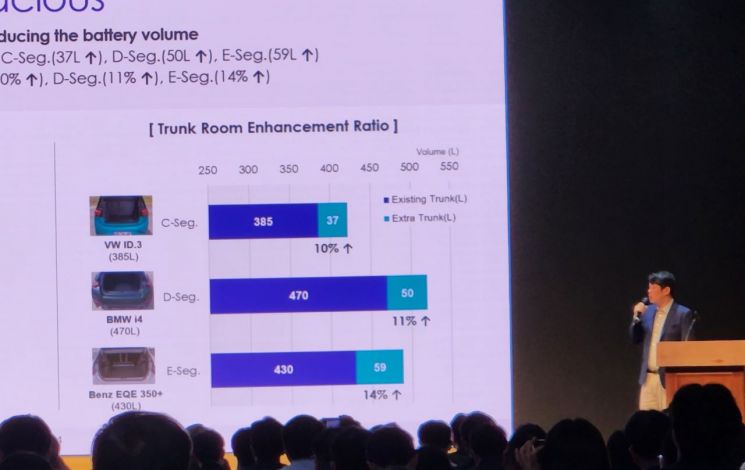

Ahn Ji-woo, head of next-generation product planning for the medium and large battery division at Samsung SDI, focused his presentation on the potential and possibilities of all-solid-state batteries. Ahn said, "All-solid-state batteries are safe and can reduce weight by up to 9% (based on mid-size vehicles) compared to vehicles equipped with high-nickel batteries," adding, "(Samsung SDI) will complete the development of medium and large all-solid-state battery technology by 2025 and establish a mass production system for all-solid-state batteries by 2027." Since March last year, Samsung SDI has been constructing a pilot line for all-solid-state batteries called 'S-Line' at its research center in Suwon, Gyeonggi Province. Once the line is completed in the first half of this year, sample production is planned for the second half.

An Ji-woo, Head of Next-Generation Product Planning Group in the Medium and Large Battery Division at Samsung SDI, is explaining the strengths of lightweight all-solid-state batteries. Photo by Jeong Dong-hoon

An Ji-woo, Head of Next-Generation Product Planning Group in the Medium and Large Battery Division at Samsung SDI, is explaining the strengths of lightweight all-solid-state batteries. Photo by Jeong Dong-hoon

Ahn highlighted Samsung SDI's unique advantages in all-solid-state batteries, including ▲maximizing energy efficiency through NCA (Nickel-Cobalt-Aluminum) cathode materials ▲excellent output and charging performance of sulfide-based solid electrolytes ▲stacking manufacturing method (layering battery materials) ▲and a 'new anode' technology that prevents lithium dendrites (branch-like lithium crystal formations on the anode during battery use).

Ahn projected the total battery market size in 2030 to be 3600GWh, with the all-solid-state battery market accounting for 40GWh. This is a more conservative forecast compared to SNE Research's estimate. SNE Research predicted that global all-solid-state battery production capacity will gradually increase from 0.06GWh last year to 1GWh in 2025, 149GWh in 2030, and 950GWh in 2035.

The two company representatives who presented on the day agreed on the 'high costs' of all-solid-state battery production and R&D but showed different levels of commitment to commercialization. However, LG Energy Solution is also currently developing all-solid-state batteries with a goal of commercialization after 2030.

Jang emphasized that recent trends in the battery and electric vehicle industry highlight the increasing importance of innovation for cost reduction. He said, "About 100 years ago, Ford in the U.S. reshaped the automobile market by launching the 'Model T,' which reduced vehicle prices to a quarter of the previous level. Within 20 years after the Model T launch, the number of automobile companies decreased from 265 to 44." He added, "Tesla's recent price reduction strategy also seems intended to reorganize the market." He continued, "To lower electric vehicle prices, batteries will be the most important factor," and "I believe domestic battery companies must lead this trend through process innovation."

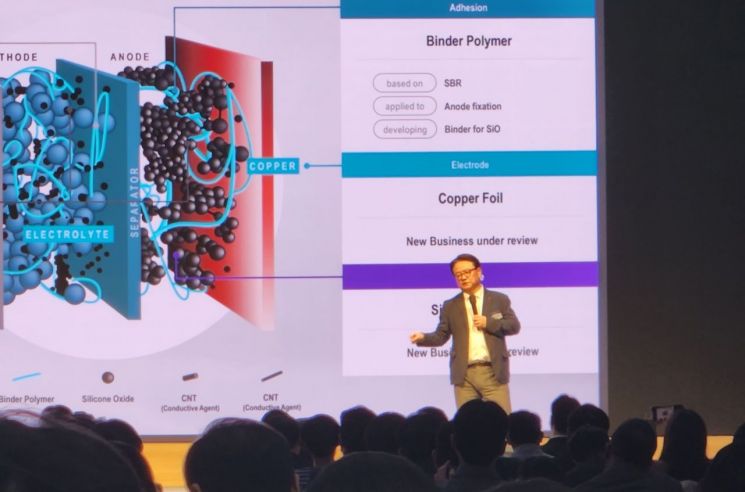

LG Chem: "Exploring copper foil business to add to value chain... Considering both acquisition and in-house development"

In the presentation, LG Chem mentioned the possibility of adding the copper foil business to its value chain. Choi Young-min, head of LG Chem's Battery Materials Research Center (Executive Director), said, "We are currently exploring copper foil (for internalization)," adding, "We are considering both acquisition and in-house development."

In 2021, LG Chem invested 40 billion KRW in shares of the Chinese copper foil company 'Dofu.' Last year, there were speculative reports about LG Chem entering the acquisition battle for Iljin Materials. However, this is the first time that internal plans for the copper foil business have been publicly disclosed through an internal source. LG Chem aims to become the 'No.1 global battery materials company' by adding core battery materials to its value chain. Currently, LG Chem produces battery materials such as cathode materials, separators, and anode binders.

Choi Young-min, head of LG Chem's Battery Materials Research Center, is explaining LG Chem's battery materials value chain. Photo by Jung Dong-hoon

Choi Young-min, head of LG Chem's Battery Materials Research Center, is explaining LG Chem's battery materials value chain. Photo by Jung Dong-hoon

Regarding the increasingly competitive battery market, Choi said, "We are focusing on developing LFP (Lithium Iron Phosphate) series, cobalt-free, and manganese-rich cathode materials."

Meanwhile, Oh Ik-hwan, vice president of SNE Research, announced at the seminar that "Global electric vehicle sales are expected to reach about 80 million units by 2035, and electric vehicle battery demand will grow from 687GWh in 2023 to 5.3TWh in 2035." In terms of value, this is expected to grow to 616 billion USD (approximately 815 trillion KRW) by 2035, which is about five times this year's forecast of 121 billion USD.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.