Korea Institute of Materials Science

Domestic researchers have developed the world's first building-attached solar technology capable of double-sided power generation.

The Korea Institute of Materials Science (KIMS) announced on the 10th that Dr. Jeongdae Kwon's research team at the Nano Surface Materials Research Division, in collaboration with Professor Poonggeun Song of Pusan National University and Professor Myunghoon Shin of Korea Aerospace University, developed a flexible substrate integrated with a light-scattering structure using a laser transfer process. They also succeeded in realizing the world's first flexible substrate transparent thin-film solar cell with high double-sided power generation by minimizing rear-side light reflection through refractive index matching.

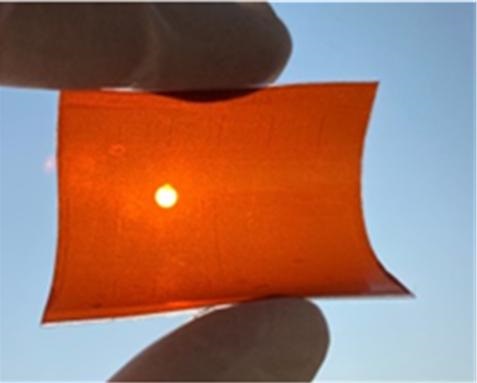

Bifacial building-integrated solar cell developed by the Korea Institute of Materials Science. Photo by Korea Institute of Materials Science

Bifacial building-integrated solar cell developed by the Korea Institute of Materials Science. Photo by Korea Institute of Materials Science

The light absorption layer of transparent thin-film solar cells is extremely thin, less than 300 nanometers (nm), so a light-scattering structure is introduced to increase the generated current. Until now, research has mainly created light-scattering structures using etching and photolithography processes applied to transparent oxide semiconductors in solar cells. However, these manufacturing processes are complex or prone to defects, making it difficult to apply them to flexible substrates.

The research team deposited a laser absorption layer on a zinc oxide thin film with a light-scattering structure. They then manufactured a flexible substrate about 20 micrometers (μm) thick, fused with a light-scattering structure identical in shape to the original, and developed a laser transfer method to overcome the limitations of existing processes. The 20-micrometer-thick flexible substrate formed at this stage exhibited a light scattering degree of 51.9%, and the silicon thin-film solar cell formed on the opposite side showed a 9.7% efficiency improvement compared to flexible substrate solar cells without light scattering. This process enables the formation of solar cell substrates ranging from as small as 5×5 cm to as large as 14×14 cm, minimizing defects caused by the structure and possessing characteristics suitable for existing solar cell processes.

By transferring and fusing structures that effectively generate light scattering without reducing the transmittance of the flexible substrate using lasers, the power generation efficiency of solar cells was improved. In particular, the structure grows on the opposite side of the light-scattering structure, preventing defects caused by the structure itself and minimizing defects due to the intrinsic properties of the materials. It is expected to be applicable to various thin-film solar cell absorbers and serve as a benchmark for high-efficiency flexible substrate transparent thin-film solar cells for BIPV (Building-Integrated Photovoltaics). Additionally, a window layer design that minimizes rear incident light loss reduces reflected light, securing a high level of double-sided power generation.

The flexible substrate transparent thin-film solar cell technology can be attached to and generate power from all elements constituting a building without additional material design compared to existing buildings. It is expected to effectively replace the solar cell market formed on glass and metal substrates, which have relatively higher efficiency, at a lower cost. Furthermore, it is anticipated to be applicable to more diverse fields such as agrivoltaics.

Principal researcher Kwon said, "We developed a simple and process-friendly flexible substrate transparent thin-film solar cell fused with a light-scattering structure," adding, "We expect it to enable the realization of a double-sided power generation BIPV system with an improved light absorption mechanism."

The research results were published on the 27th of last month in the international journal of electronics engineering, npj flexible electronics (IF: 12.019).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)