The introduction of Tesla's 48V-based electrical and electronic architecture has been interpreted as a sign of Tesla's increased dominance over its parts suppliers.

On the 10th, the Korea Automotive Technology Institute released a report titled 'The Significance of Tesla's Adoption of 48V Architecture,' asserting this viewpoint. Recently, Tesla declared that it will implement a 48V-based electrical and electronic architecture in the Cybertruck, targeted for mass production in the second half of this year, as well as in future vehicles and the humanoid robot Optimus.

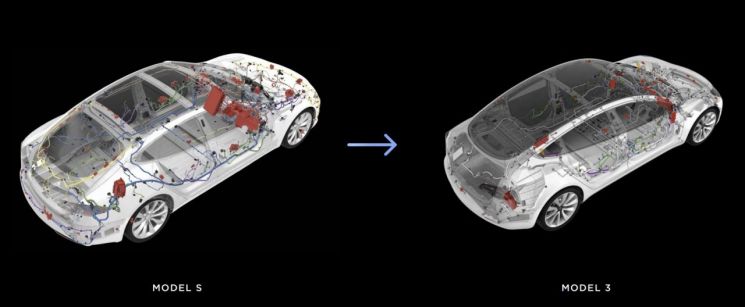

Switching from 12V to 48V reduces current to about a quarter, thereby improving power efficiency. It decreases power loss in electronic components such as lighting, infotainment, and steering, and also enhances the efficiency of air conditioning and power conversion systems. Additionally, it simplifies wiring and reduces wire weight, contributing to vehicle weight reduction and cost savings. Because current decreases, wire weight can be reduced, and it becomes easier to equip computing and audio systems that require high power, as well as 48V-customized accessories.

However, the problem is that most current vehicles use 12V as the standard voltage for electronic components, making 48V parts difficult to source. Therefore, insisting on 48V may lead to higher supply costs in the short term compared to existing standards.

Nonetheless, Tesla's push to adopt a 48V-based architecture indicates its confidence in creating its own parts ecosystem. This move is seen as an extension of Tesla's strategy of simultaneously pursuing architectural and modular innovation.

The Korea Automotive Technology Institute evaluated Tesla's recent announcement as an example demonstrating Tesla's sufficiently strengthened control over the parts ecosystem. It means Tesla can maintain design leadership and independence while securing stable procurement of parts.

Lee Hojung, a senior researcher at the Korea Automotive Technology Institute, said, "If the practical benefits of switching to 48V are proven, existing automakers are likely to face pressure to catch up. However, due to relational and organizational inertia with their suppliers, even if existing companies recognize the necessity of switching to 48V, the actual transition will take a long time."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.