#. At a private construction site A located in Seoul, the ready-mixed concrete (Remicon) supplier was unable to deliver 2 out of 7 trucks of Remicon (12㎡ out of 42㎡), resulting in a complete halt of the entire construction. At site B, a public construction project underway in Gyeonggi-do, 34 trucks of Remicon (200㎡) were ordered, but the supplier could not provide even one truck, causing the concrete pouring to stop and the construction to be suspended.

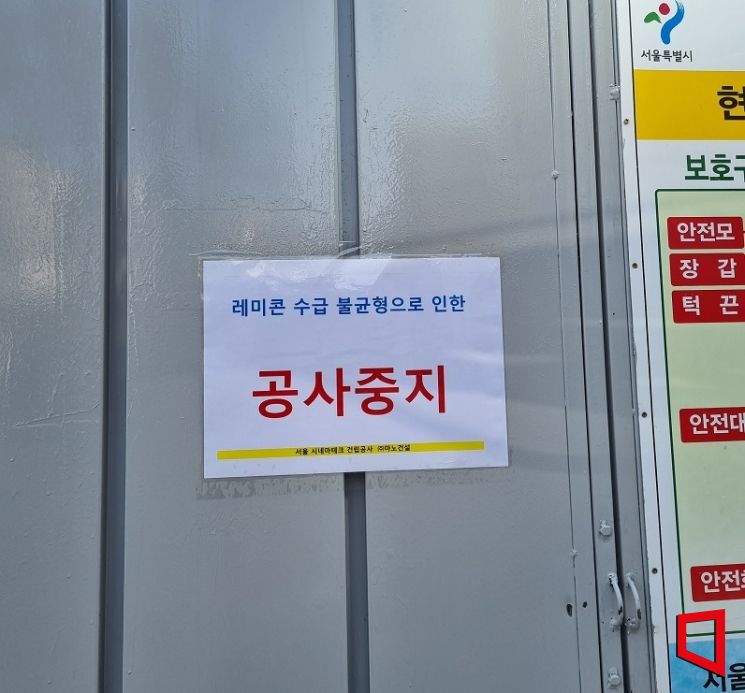

A construction site in Seoul halted work due to an imbalance in ready-mixed concrete supply. / Photo by Im Onyu

A construction site in Seoul halted work due to an imbalance in ready-mixed concrete supply. / Photo by Im Onyu

The Korea Construction Association recently announced on the 30th that construction sites are being halted or delayed due to a shortage of cement supply, and requested the government to establish countermeasures at the governmental level.

According to an emergency survey conducted by the association targeting medium to large companies ranked within the top 100, 98 out of 154 sites (63.6%) experienced construction stoppages or delays due to unstable supply of cement and Remicon since March. In particular, public construction projects where Remicon is supplied as government-procured materials cannot adjust unit prices, and only 4 out of 42 surveyed sites reported normal supply of cement and Remicon.

The association pointed out, "Cement production sharply declined due to overlapping schedules of equipment maintenance and remodeling in the cement industry, and this is expected to continue throughout the first half of the year, raising concerns about prolonged supply shortages." They added, "If no measures are taken and the construction peak season begins after April, there could be a worst-case scenario including rapid price hikes of materials, increased construction costs, delays in apartment move-ins, and delays in social overhead capital (SOC) projects."

The association identified that out of the industry's total 34 production facilities (kilns), 15 are undergoing maintenance, making cement production impossible for 4 to 5 months. They further stated, "to minimize the impact such as construction stoppages caused by cement supply shortages, the cement industry’s equipment maintenance and remodeling schedules should be adjusted, and a consultative body should be formed to stabilize supply through appropriate production."

Additionally, they said, "The government should issue guidelines to relevant ministries and affiliated agencies to allow extension of construction periods and adjustment of contract amounts when public construction projects are halted or delayed due to material supply instability, and establish institutional grounds to exempt private projects from liquidated damages."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)