Largest North American Global Battery Independent Factory

Cylindrical 4.2 Trillion KRW · ESS LFP 3 Trillion KRW Scale

LG Energy Solution has decided to expand its U.S. Arizona plant, which was under investment reconsideration due to high interest rates and exchange rates, to four times the originally planned scale. This investment reflects confidence in the growth trend of the North American battery market.

LG Energy Solution announced that it will invest 7.2 trillion KRW to build a new cylindrical and ESS (Energy Storage System) LFP battery plant in Queen Creek, Arizona. The total production capacity will be 43GWh, making it the largest global battery independent production plant located in the North American region. Queen Creek is a city located 60 km from Phoenix, the capital of Arizona, about a 40-minute drive away.

On the same day, LG Energy Solution decided at its board meeting to resume the construction of the Arizona cylindrical battery independent production plant, which had been reconsidered last June. The investment amount and production scale were significantly expanded to 4.2 trillion KRW and 27GWh, respectively. Additionally, a separate investment of 3 trillion KRW will be made on the same site to build an ESS LFP battery production plant with a capacity of 16GWh. This is the first time a global battery company is building a dedicated ESS battery production plant.

In March last year, LG Energy Solution announced plans to invest 1.7 trillion KRW in Arizona to build an 11GWh cylindrical battery production plant. Subsequently, due to the surge in investment costs caused by the worsening global economic environment, the company announced that it would carefully reconsider the timing, scale, and details of the investment.

LG Energy Solution stated, "Following the implementation of the U.S. Inflation Reduction Act (IRA), customer demand for stable supply of high-quality and high-performance batteries within the North American region has greatly increased. Accordingly, we have decided to significantly expand the previously planned investment to actively respond to customer and market demand."

'Cylindrical Battery Leader' LG Energy Solution to Build Independent Plant for 350,000 Electric Vehicles

LG Energy Solution's new cylindrical battery dedicated production plant will begin construction this year, aiming for completion and mass production by 2025. The plant will produce the main model, the 2170 cylindrical battery, and supply it to major U.S. electric vehicle customers.

Among domestic battery companies, LG Energy Solution is the first to build a cylindrical battery dedicated production plant in the North American region. The plant is expected to have an annual production capacity of 27GWh, which is enough to produce 350,000 high-performance pure electric vehicles.

Through this investment, LG Energy Solution plans to lead the rapidly growing cylindrical battery market and strengthen its position as the world's top battery company. In fact, the global cylindrical battery market is expected to nearly double from 36.8 trillion KRW last year to 70.2 trillion KRW by 2026.

LG Energy Solution said, "As companies using cylindrical batteries, especially electric vehicle startups, are increasing in North America, the market is growing rapidly. Through this large-scale investment, we will reliably supply high-quality products to our customers."

North America Becoming a Hub for Eco-Friendly Energy... Building the 'World's First' Dedicated ESS Battery Plant

For the first time among global battery companies, LG Energy Solution will also build a dedicated ESS battery production plant.

With a total investment of 3 trillion KRW and a capacity of 16GWh, this plant will produce pouch-type LFP batteries independently developed by LG Energy Solution. Construction will start this year, with mass production targeted for 2026. The global ESS market is also expected to grow rapidly as countries expand policy support for renewable energy. In particular, the North American market is expected to lead global growth due to the Inflation Reduction Act and other factors.

According to market research firm SNE Research, the North American ESS market is projected to grow more than tenfold from 14.1GWh in 2021 to 159.2GWh by 2030.

The ESS-dedicated LFP batteries and systems produced by LG Energy Solution are characterized by advantages over competitors in terms of energy density and SOC (State Of Charge) accuracy. Moreover, local production will reduce logistics and tariff costs, enhancing price competitiveness.

Unlike competitors who focus solely on ESS battery supply, LG Energy Solution has comprehensive service capabilities covering ESS supply, business planning, design, installation, maintenance, and repair through its U.S. ESS SI subsidiary, 'LG Energy Solution Vertrek.'

Based on these capabilities, LG Energy Solution plans to strengthen its customer portfolio and continuously expand high-profit business models such as data-driven services to secure a definitive number one position in the North American market.

Securing Overwhelming Advantage in the North American Market with Differentiated Production Capabilities and Product Portfolio

Last year, LG Energy Solution announced plans to strengthen competitiveness in the North American market by focusing on ▲region ▲customers ▲products ▲smart factories. This investment is evaluated to enable the company to secure a more overwhelming advantage in the leadership competition expected in the rapidly growing North American market.

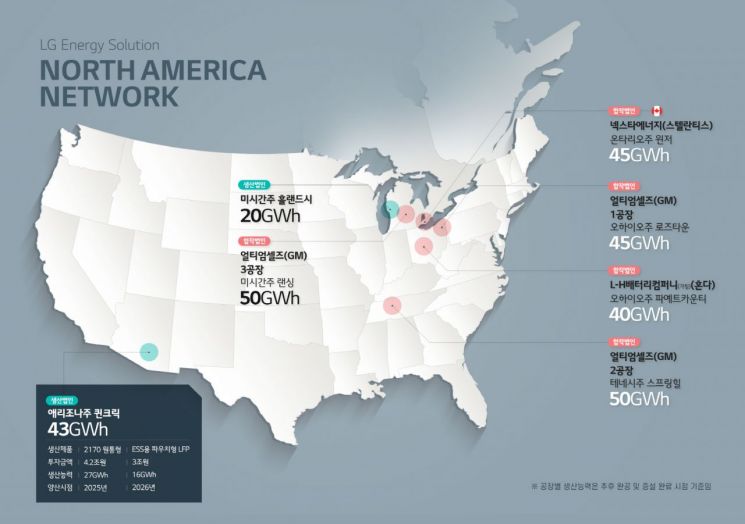

With this new plant, LG Energy Solution will have a total of seven production bases in the North American region. Currently, it operates an independent plant in Michigan and the first joint plant with GM in Ohio, and is constructing the second GM plant in Tennessee, the third GM plant in Michigan, the joint battery production plants with Honda in Ohio and Stellantis in Ontario, Canada.

The product portfolio will also be further diversified. Currently, LG Energy Solution offers electric vehicle (EV) pouch and cylindrical batteries as well as ESS LFP batteries, making it the battery company with the most diverse product portfolio in the North American region. Through this, the company plans to secure more customers in the North American market.

LG Energy Solution will fully introduce the latest smart factory systems such as remote support, manufacturing intelligence, and logistics automation in the new plant. This will enable stable response to customer demand and strengthen leadership in the North American battery business by adding mass production know-how and differentiated technological competitiveness.

Kwon Young-soo, Vice Chairman and CEO of LG Energy Solution, said, "The construction of the independent plant in Arizona will be an opportunity to firmly secure the rapidly growing North American electric vehicle and ESS markets. We will further strengthen our differentiated global production capabilities and unique product competitiveness to provide the world's best customer value."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.