On the 10th, Kyungpook National University announced that Professor Park Seong-hyeok's team from the Department of Materials Science and Engineering developed a new magnesium alloy for ultra-high-speed extrusion that can be manufactured at extrusion speeds more than 20 times faster than existing ones.

This is expected to maximize the production efficiency of magnesium, which is attracting attention as a future lightweight component with the world's highest extrusion speed.

Magnesium is the lightest structural metal material applicable to transportation equipment such as vehicles, aircraft, and railroads, and has the advantage of high strength relative to its low density.

It can reduce weight by up to 78% compared to steel and up to 35% compared to aluminum. However, magnesium has significantly lower extrudability than aluminum, requiring extrusion?a representative manufacturing process for parts?to be conducted at slow speeds. This results in high production costs, which have been a major obstacle to industrial application.

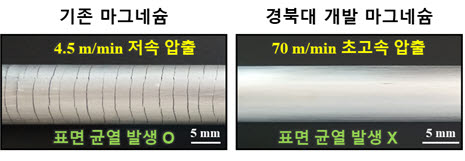

The magnesium developed by Professor Park Seong-hyeok's team does not use expensive rare earth elements, making it inexpensive, and enables ultra-high-speed extrusion of over 70 meters per minute, which is more than 20 times faster than the extrusion speed of commercially available high-strength magnesium.

This is the world's highest extrusion speed, allowing parts to be manufactured faster than aluminum. In particular, while extrusion speed generally lowers the strength of parts, the magnesium developed by Professor Park's team maintains high strength even at ultra-high-speed extrusion, overcoming the inverse relationship between extrusion speed and strength.

They also confirmed the possibility of mass production of high-strength magnesium extruded parts by successfully performing ultra-high-speed extrusion of the developed magnesium using large-scale mass production equipment owned by companies.

This research was led by Professor Park Seong-hyeok and doctoral student Jin Sang-cheol, and related research results have been published in a total of 10 papers in international journals ranked within the top 15% of the Journal Citation Reports (JCR) over the past three years, including the February 21 issue of the Journal of Magnesium and Alloys (JMA), the number one journal in the field of metallic materials with a JCR ranking in the top 0.63%. Among these, five papers were published in JMA. Additionally, two domestic patents related to the technology have been registered, and two overseas patents and one domestic patent have been filed.

Professor Park Seong-hyeok said, “Through intensive research over the past eight years, we have developed a new magnesium alloy that overcomes the limitations of existing magnesium. The developed magnesium alloy simultaneously possesses productivity and physical properties that surpass conventional wisdom, and its effectiveness in industrial settings has been verified. Through collaboration with related companies, commercialization into various parts is expected to secure a leading position in the global market for lightweight electric vehicles and future mobility.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.