Hyundai Motor and Kia Hit Record High Proportion of Contract Workers... Impact of Senior Contract System

New Regular Production Hires... Accelerating Workforce Structure Shift for Future Vehicles

[Asia Economy Reporter Su-yeon Woo] The proportion of contract workers among all employees at Hyundai Motor Company and Kia has reached an all-time high. This is due to the ‘Senior Contract System,’ which rehires retirees on a short-term basis. Hyundai Motor Company will hire regular production workers for the first time in 10 years this year. Kia will also recruit additional production workers in the second half of this year, following last year. They are accelerating the transition of their workforce structure in line with the era of future vehicles.

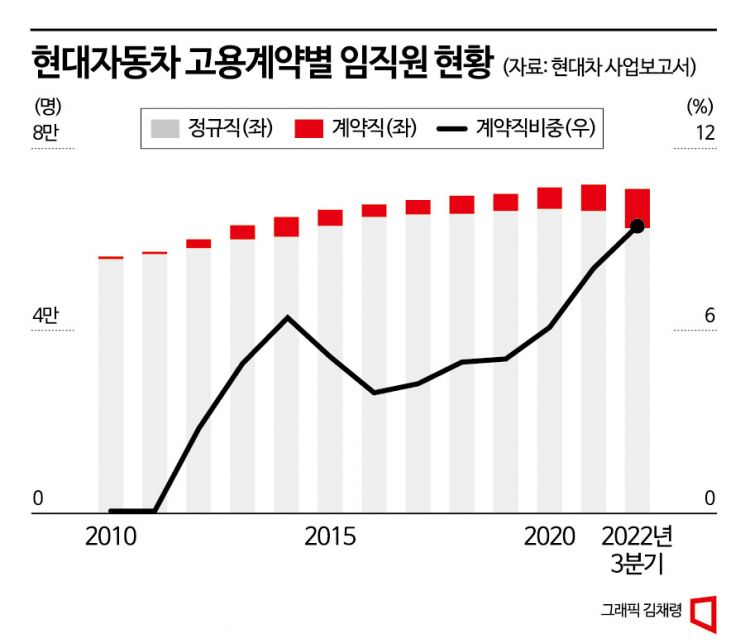

According to a comprehensive report from our coverage on the 10th, as of the end of the third quarter last year, the proportion of contract workers among all Hyundai Motor employees was 9.7%. For Kia, it was 3.3%. The number of contract workers is 6,886 at Hyundai Motor and 1,164 at Kia. This is the highest level since Hyundai Motor and Kia began disclosing employee status by employment contract type in 2010. Even considering Hyundai Motor alone, about 20% of the approximately 32,000 production workers, or one in five, are contract workers under the Senior Contract System.

Background for the Increase in Hyundai Motor’s Contract Workers

Hyundai Motor’s production workforce is divided into regular employees, contract workers under the Senior Contract System, and in-house subcontracted workers. To enhance labor flexibility and profitability, the company mixes these three employment types appropriately to structure its production workforce.

The company introduced the Senior Contract System, which limits the contract period to less than two years, ahead of the revised Dispatch Act enforcement in 2012. At the same time, through labor-management agreement, it decided to convert in-house subcontracted workers to regular employees. From 2012 to 2020, 9,500 in-house subcontracted workers were converted. As the number of regular employees increased, the proportion of contract workers remained at 4-6% until 2018. However, after Hyundai Motor’s labor and management introduced the ‘Senior Contract System’ in 2019, the proportion rose sharply.

The Hyundai Motor labor union estimates that about 10,000 employees retired over the five years from 2018 to last year. In 2023 alone, about 2,600 employees retired. By 2028, more than 2,000 production workers are expected to retire annually. A significant number of these retirees are expected to work as contract workers under the Senior Contract System. From the company’s perspective, the ‘Senior Contract System’ was not a bad choice. It allowed for a natural reduction in workforce while enabling discussions with the union about new hires. The company needed new employees who are low-paid and flexible to job changes rather than high-paid, rigid senior workers.

"In the Era of Future Vehicles, the Role of the Labor Union Must Be Redefined"

During the internal combustion engine vehicle era, the labor union advocated for converting in-house subcontracted workers to regular employees and reducing contract workers. The biggest issue was ‘job security’ for production workers. Every year, the issue of converting contract workers to regular employees was always on the wage and collective bargaining negotiation table. Recently, the union has even demanded the abolition of the Senior Contract System and wage peak system, as well as an extension of the retirement age.

However, there is a consensus that the union must also change in the era of future vehicles. As electric vehicle production reduces the number of vehicle parts, the number of required production workers will also decrease. Additionally, Hyundai Motor cannot be exempt from the spread of automation in global automobile factories. Both labor and management see the reduction in simple production worker numbers as an unavoidable near-future reality. The union’s recent restraint from indiscriminate strikes under the banner of job security is in this context. The union is expected to focus on next-generation tasks such as fair performance, quality improvement, and strengthening vocational training.

Future Vehicle Employment Should Rather Increase

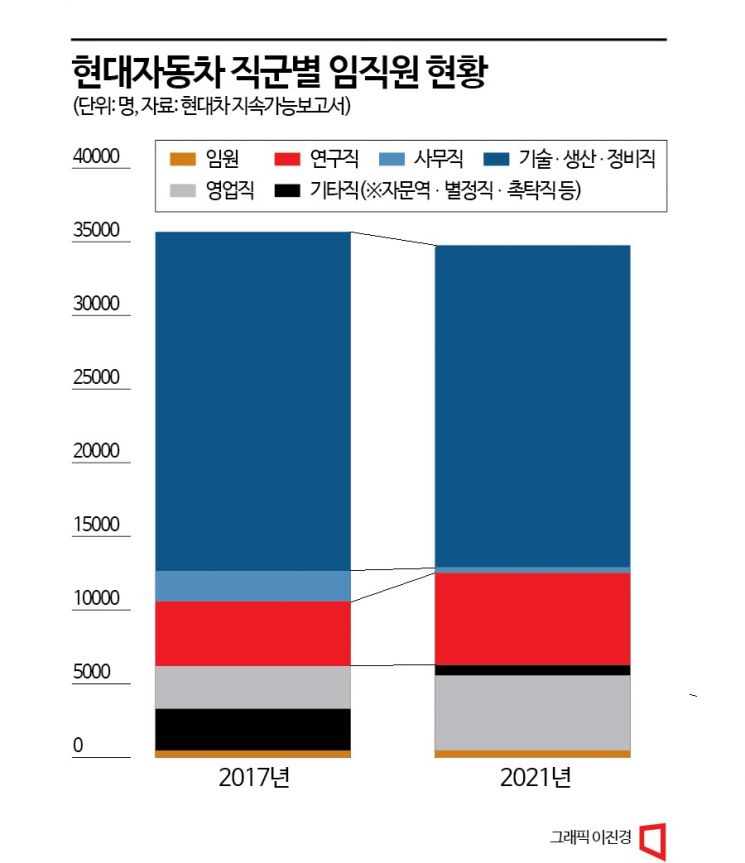

Hyundai Motor and Kia are considering qualitative structural transformation rather than artificial adjustment of workforce numbers. While the number of simple production workers will decrease in the future vehicle era, the total employment including vehicle software (SW) personnel will increase. As production processes become automated, the number of production workers performing simple assembly will decrease, but additional engineers to develop and control automated equipment will be needed. Technicians capable of handling software will also be necessary to repair vehicles equipped with electronic devices.

Therefore, experts are paying attention to the abolition of age, major, and academic background restrictions in Hyundai Motor and Kia’s new recruitment. This means they will not only recruit for simple assembly production jobs. There are also calls to secure a talent pool with potential to grow into production engineers through in-house group training.

Lee Hang-gu, a research fellow at the Korea Automotive Technology Institute, said, "In the long term, software personnel should fill the positions vacated by production workers retiring at Hyundai Motor and Kia," adding, "In the era of future vehicles, employment should not be reduced but rather increased." He emphasized, "There is a serious shortage of software personnel on site, and for workforce structural transformation, the classification of future vehicle industry job categories must be prioritized."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.