[Asia Economy Reporter Jang Hyowon] Konic Automation is showing strength following news that it supplied robots to Coupang's logistics center. Konic Automation has applied a fulfillment system using logistics robots (AGV) to Coupang, a major domestic logistics distribution company, and the largest e-commerce company in Korea.

As of 10:14 AM on the 8th, Konic Automation is trading at 4,675 KRW, up 6.37% from the previous trading day.

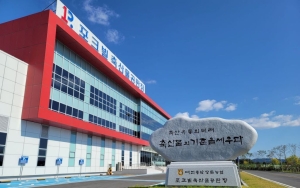

According to industry sources on the day, Coupang's Daegu Fulfillment Center (hereafter Daegu FC), which had been shrouded in secrecy since its completion in March last year, was recently unveiled to the media. The Daegu FC, spanning the size of 46 soccer fields (from basement level 2 to ground level 10), is equipped with cutting-edge logistics technologies such as unmanned transport robots (AGV), sorting bots, and unmanned forklifts in its main logistics operations building.

On the 7th floor, over 1,000 unmanned transport robots are in operation. These robots deliver shelves holding hundreds of products (up to 1,000 kg) to employees within an average of 2 minutes. Coupang has fully automated product shelving and picking operations through these robots, which can operate 24 hours a day, 365 days a year.

The 1st floor is a space where sorting bots operate in large numbers. Sorting bots are advanced logistics robots that eliminate all the cumbersome tasks previously done by humans, from checking shipping labels to sorting and moving products.

Coupang has invested approximately 6.2 trillion KRW over the past 12 years solely in building its domestic logistics network. It currently has over 100 logistics infrastructures across 30 regions nationwide. Coupang plans to continuously increase the adoption of automated logistics technologies at Daegu FC, which is expected to significantly increase delivery volumes.

Meanwhile, Konic Automation, established in 1994, operates in the semiconductor, display, and secondary battery sectors, developing ▲control software solutions ▲smart factory solutions ▲IT infrastructure solutions.

Konic Automation developed the world's first automated quality inspection system for cathode materials, K-LAS, which is supplied to EcoPro BM and EcoPro EM.

A Konic Automation representative stated, “We have supplied a total of 1,100 picking and sorting robots to Coupang,” adding, “We have applied a fulfillment system using AGVs to the largest domestic e-commerce company and are preparing for full-scale supply to domestic distribution platform companies.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.