Full Lineup of Anode Materials: Natural Graphite, Artificial Graphite, and Silicon Anode Materials

[Asia Economy Reporter Choi Seoyun] POSCO Holdings has begun preparations for the production of next-generation anode materials, specifically silicon anode materials.

On the 27th, POSCO Holdings decided to invest 59.1 billion KRW in its subsidiary POSCO Silicon Solution, which possesses silicon anode material production technology.

POSCO Silicon Solution will commence construction of the first phase of silicon anode material production facilities with an annual capacity of 450 tons at the Yeongilman Industrial Complex in Pohang, Gyeongbuk, around June. The goal is to complete the facility by the first half of 2024.

Silicon anode materials can increase energy density by about four times compared to graphite anode materials, which are currently mostly used in lithium-ion batteries. This next-generation anode material can improve electric vehicle driving range as well as reduce charging time.

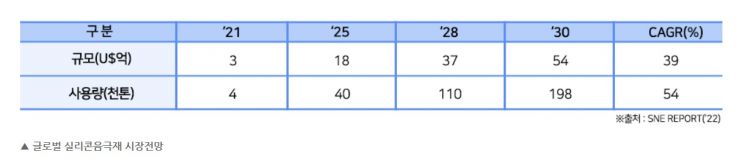

Domestic and international battery manufacturers are focusing on developing technologies to increase the silicon anode material content. The silicon anode material market size is expected to grow annually by 34% until 2030. The silicon anode material content, currently less than 5%, is projected to expand to over 10% by 2025 and over 25% by 2030.

The POSCO Group has established the world's first full value chain for secondary battery materials. Aiming to diversify its anode material business, the group acquired silicon anode material developer Terra Technos in July last year and renamed it ‘POSCO Silicon Solution’ to promote the next-generation silicon anode material business. The plan is to establish a production system with an annual capacity of 25,000 tons of silicon anode materials by 2030.

POSCO Holdings’ Future Research Institute, Pohang Institute of Industrial Science and Technology (RIST) technology capabilities, and POSCO Chemical’s production know-how have been fully mobilized to swiftly prepare for investment in production facilities.

POSCO Silicon Solution’s competitiveness lies in its continuous production technology for silicon anode materials, which offers higher productivity compared to other companies. In particular, through battery sample tests, it has been evaluated to demonstrate equal or superior basic characteristics such as capacity and expansion rate compared to competitors.

Once the silicon anode material production facility investment is completed, the POSCO Group will have a full lineup in the anode material sector, covering natural graphite, artificial graphite, and silicon anode materials.

Operating manufacturing equipment at POSCO Chemical's artificial graphite anode material plant

Operating manufacturing equipment at POSCO Chemical's artificial graphite anode material plant Photo by POSCO Holdings

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.