Jeongi-yeon Develops Hybrid Zinc-Manganese Redox Flow Battery

Structurally Safer Than Commercial Secondary Batteries

Uses Zinc-Manganese Instead of Chinese Vanadium for Cost-Effective and Improved Performance

[Asia Economy Reporter Kim Bong-su] The Korea Electrotechnology Research Institute (KERI) announced on the 9th that Dr. Park Jun-woo's team at the Next-Generation Battery Research Center and Professor Park Min-jun's team at Pusan National University have developed a technology that surpasses the limitations of existing redox flow batteries. Attention is focused on whether this will lead to the commercialization of affordable next-generation batteries without fire and explosion risks.

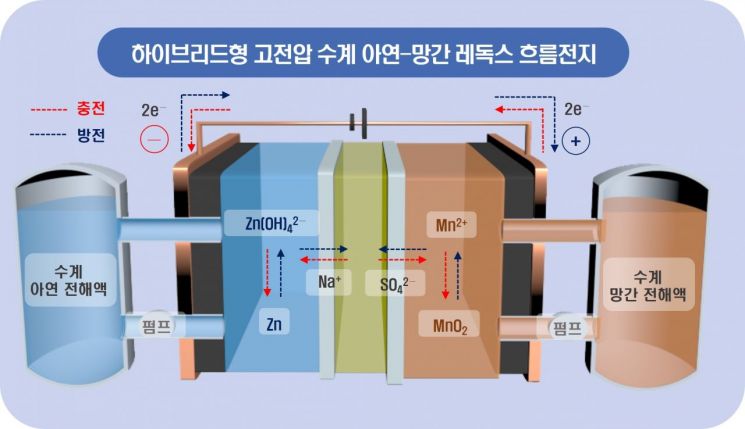

The Redox Flow Battery is a term combining the words Reduction, Oxidation, and Flow. It operates on the principle that electrons move from the negative electrode (-) to the positive electrode (+) with the help of an electrolyte through chemical reactions of oxidation and reduction, generating electrical energy. Unlike conventional secondary batteries, it separates the part where the chemical reaction occurs from the part where electricity is stored, enabling independent design of output and capacity and allowing for large-scale batteries. Additionally, it does not emit exhaust gases and poses no fire or explosion hazards.

The problem is that the main core material of current redox flow batteries, 'vanadium,' is an expensive metal that we rely on imports from countries like China for. The voltage, which determines the battery's performance, is also lower in vanadium redox flow batteries compared to commercial lithium secondary batteries, resulting in about 10-15% lower efficiency.

The research team used manganese and zinc, which are relatively inexpensive and have stable supply, instead of costly vanadium. In particular, the unique dual ion-exchange membrane structure allows the simultaneous use of alkaline zinc electrolyte and acidic manganese electrolyte, enabling a high potential difference.

There was also a problem. When the manganese cathode active material was oxidized, it did not revert to its original state but was deposited on the electrode and ion-exchange membrane surfaces. To improve manganese's low reversibility issue, the research team applied a 'carbon reduction method' to deposit bismuth metal on the electrode surface. They used electrolytes containing nickel, magnesium, copper, and cobalt ions. Bismuth, with excellent electrical conductivity, enhanced electron transfer. Electrolytes optimized through electrochemical performance analysis acted as catalysts, significantly improving the battery's stability (suppressing side reactions of active materials), performance, and lifespan.

Subsequently, the effectiveness of the developed technology was verified through various analyses such as Transmission Electron Microscopy (TEM), X-ray Photoelectron Spectroscopy (XPS), and Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES). As a result, the hybrid zinc-manganese redox flow battery developed by KERI and Pusan National University achieved higher voltage (1.3V -> 2.52V) and more than 10% improvement in energy efficiency compared to existing vanadium-based batteries.

Dr. Park Jun-woo of KERI stated, "This is a new concept redox flow battery technology combining low-cost zinc and manganese materials with metal ion catalyst technology that enhances reversibility," adding, "This achievement will greatly contribute to the expansion of next-generation long-cycle large-capacity redox flow batteries."

The research results were published in the international energy journal 'Energy Storage Materials.' KERI plans to further expand and develop this technology using the country's first 'Gwangju Redox Flow Battery Test and Certification Center,' established last year, and aims to proceed with the production of actual large-area, high-concentration cells crucial for commercialization, as well as promote private sector technology transfer.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)