Gwangju Institute of Science and Technology - California Institute of Technology Research Team

Used in Next-Generation Semiconductors and Broadband Antennas

Expected Application in High-Voltage and Flexible Devices

Self-Healing Dielectric Breakdown Strength Results of Ultra-Low Dielectric Constant Capacitors and Their Mechanical Stress-Strain Relationships and Compressive Deformation

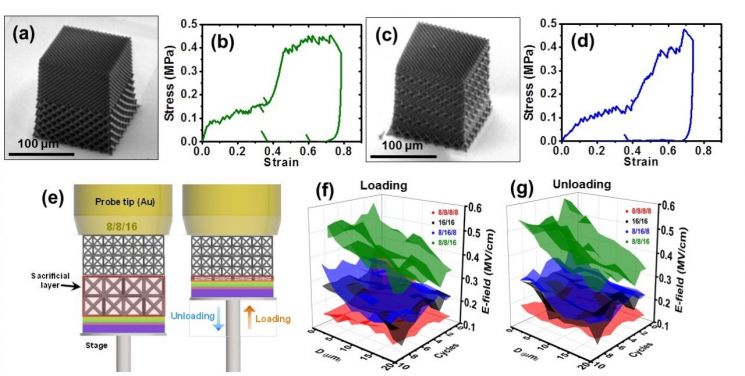

Self-Healing Dielectric Breakdown Strength Results of Ultra-Low Dielectric Constant Capacitors and Their Mechanical Stress-Strain Relationships and Compressive Deformation(a,b) Images and stress-strain relationships of ultra-low dielectric constant capacitors with bimodal density distribution

(c,d) Images and stress-strain relationships of ultra-low dielectric constant capacitors with repetitive density distribution

(e) Schematic diagram for measuring electrical/insulating properties under compressive deformation

(f) Leakage current density according to compression level and number of stress cycles during compressive deformation

(g) Leakage current density according to compression level and number of stress cycles after removal of compressive deformation / Photo by Gwangju Institute of Science and Technology

[Asia Economy Reporter Kim Bong-su] Domestic researchers have developed a metastructure capacitor (electrolytic capacitor) that can be stably used in supercomputers, broadband wireless communication, and high-voltage devices. A capacitor is an electrical component that temporarily stores a large amount of electric charge on a conductor. It is also called an electrolytic capacitor.

The National Research Foundation of Korea (NRF) announced on the 8th that Professor Kim Bong-jung's research team at Gwangju Institute of Science and Technology (GIST) collaborated with Professor Julia Greer's research team at the California Institute of Technology to develop a capacitor using a three-dimensional nanolattice structure that maintains ultra-low dielectric constant under repeated compressive deformation and continuously recovers dielectric breakdown strength.

The three-dimensional nanolattice (3D-nanolattice) is a metamaterial composed of ceramic nanotubes regularly arranged in unit cell forms, made using three-dimensional laser etching and atomic layer deposition technology. Ultra low-k dielectric refers to a low dielectric constant of 1.5 or less, and dielectric breakdown strength is the voltage at which the electrical resistance between electrically insulated materials decreases, allowing a large current to flow at a metal level.

As many next-generation electronic devices use high-voltage wiring and evolve into flexible forms that maintain reliability under mechanical deformation, the development of capacitors using low-dielectric materials with high electrical and dielectric stability is required. Previously, porosity (the volume ratio of holes to the total volume in porous materials) was increased to lower the dielectric constant of capacitors. However, materials with high porosity had limitations such as weakened mechanical strength, reduced dielectric breakdown strength, and lower thermal stability.

The research team previously developed a nanolattice capacitor with 99% porosity that could recover dielectric breakdown and ultra-low dielectric properties even under mechanical compression. However, it could only recover performance after five compression cycles and 25% small deformation, making commercialization difficult. To solve this, the team improved the existing nanolattice, which consisted of a single density and unit layer, into a heterogeneous structure mixing two layers of low density and high density. Test results showed that when stress was applied to the nanolattice, the low-density layer began to deform first, and the high-density layer was completely protected from stress until 50% of the entire lattice was deformed. Furthermore, dielectric breakdown and ultra-low dielectric properties were stably recovered during 62.5% deformation and 100 compression cycles, recording a dielectric breakdown strength up to 3.3 times higher than that of single-density nanolattices.

Professor Kim said, "This research is significant in developing ultra-low dielectric materials that simultaneously possess mechanical resilience and thermal and electrical stability," adding, "It is expected to be used in flexible electronic systems, electric vehicles, and high-voltage systems in space and aerospace fields in the future."

The research results were published online on November 15 last year in the international materials science journal Advanced Materials.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.