Professor Kangtaek Lee's Research Team at KAIST

[Asia Economy Reporter Kim Bong-su] Domestic researchers have succeeded in creating a high-performance fuel cell with more than twice the efficiency of existing models using gelatin extracted from pig skin.

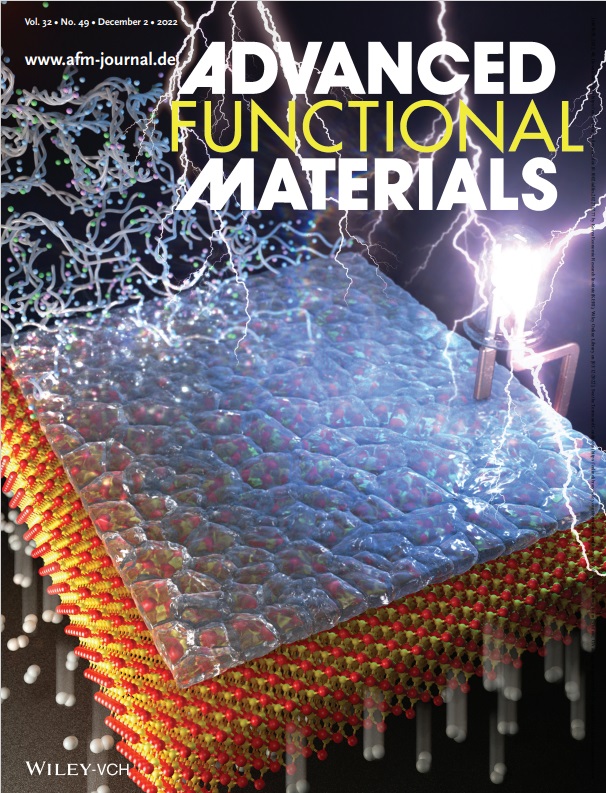

The Korea Advanced Institute of Science and Technology (KAIST) announced on the 8th that Professor Lee Kang-taek's research team from the Department of Mechanical Engineering successfully developed a high-performance reversible solid oxide fuel cell by applying a manufacturing technology for ultra-thin, highly dense multi-doped ceramic thin films at the scale of hundreds of nanometers, utilizing gelatin extracted from pig epidermis.

The reversible solid oxide fuel cell (R-SOFC) is a system capable of both hydrogen production and power generation within a single fuel cell device, making it an essential energy conversion device for realizing a carbon-neutral society. To enhance the performance of such energy devices, the development of electrodes with high activity at medium to low temperatures below 700°C is essential. Cobalt-based perovskite electrodes have been intensively studied for this purpose. However, the problem is that cobalt-based electrode materials chemically react with the commonly used zirconia (ZrO2) electrolyte at high temperatures, degrading performance. Although introducing a ceria (CeO2) functional layer between the electrode and electrolyte has been proposed, the process temperature must be limited to suppress reactions between ceria and zirconia, resulting in a thick porous structure that reduces the fuel cell's performance and stability.

The research team developed a manufacturing process for ultra-thin yet dense multi-doped ceria nano-thin films using gelatin extracted from pig epidermis and successfully applied this as a functional layer in reversible solid oxide fuel cells. Electrochemical and structural analyses confirmed that the introduction of the dense functional layer significantly reduced the oxygen ion migration path and greatly increased the electrochemical active area. The developed reversible fuel cell demonstrated more than twice the performance compared to fuel cells using conventional processes and exhibited the highest performance among fuel cells using the same materials (3.5 W/cm2 at 750°C). It also achieved world-leading performance in hydrogen production. Furthermore, the developed fuel cell device operated for 1,500 hours without degradation, demonstrating very high stability.

Professor Lee Kang-taek emphasized the significance of the research, stating, "The processes used in this study are technologies that can be easily applied to large-area mass production systems, so this technology can be applied to the commercialization of high-performance reversible fuel cells for achieving carbon neutrality."

The research results were published online on September 8 in the international journal Advanced Functional Materials and were selected as a cover paper.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)