Online Applications Open Until December 9, Training Period from January to June 2023

Graduation Ceremony for 4th Cohort on November 25, 33 Local Industry Workers Completed and Results Announced

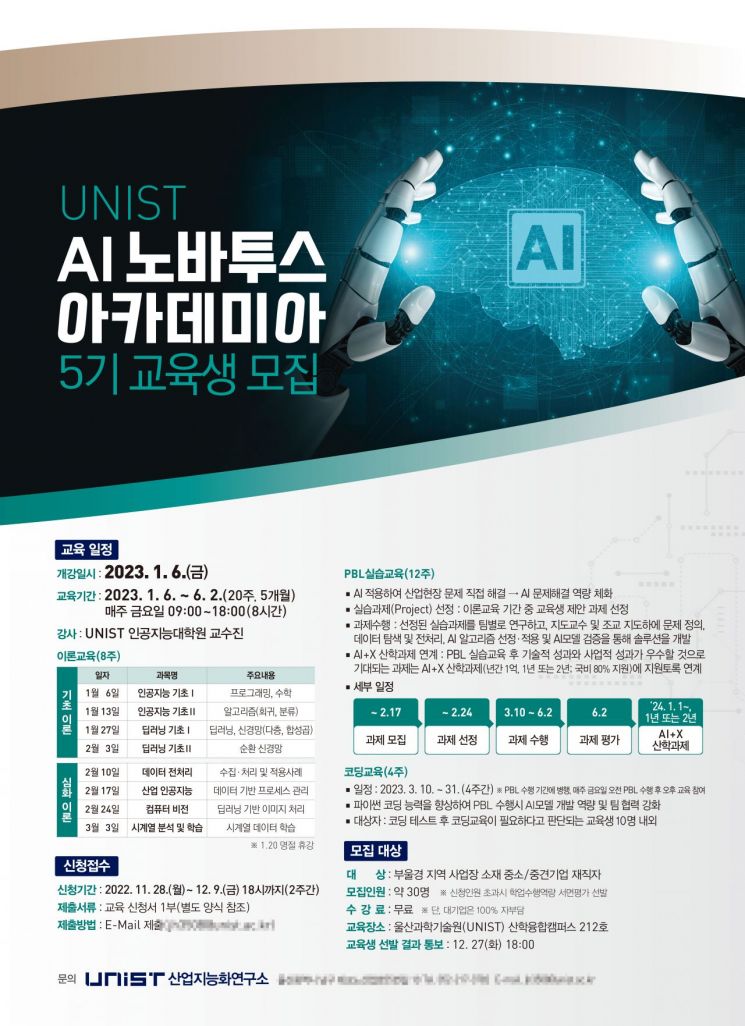

[Asia Economy Yeongnam Reporting Headquarters Reporter Dongguk Lee] UNIST is recruiting the 5th batch of trainees for the ‘AI Novatus Academia’.

AI Novatus Academia is a training program for employees in the industrial sector of the southeastern region, organized by the UNIST Artificial Intelligence Innovation Park.

Engineers working on production sites learn AI theory and practice for five months, and the program is operated as a process where they plan and solve AI projects needed by each industry.

The 5th batch of trainees will be recruited online from the 28th until December 9th. The curriculum for the 5th batch is planned to run for five months from January to June 2023.

Shim Jae-young, head of the UNIST Artificial Intelligence Innovation Park project group, said, “AI Novatus Academia is a program where you can experience the effects of applying cutting-edge AI technology to industrial sites,” adding, “We hope many engineers working in manufacturing in Ulsan as well as in Busan and Gyeongnam regions participate and achieve manufacturing innovation.”

On the 25th, the ‘AI Novatus Academia 4th Batch Graduation Ceremony’ was held. The ceremony was attended by 33 graduates and supervising professors, and presentations of nine team-based preliminary research (Project-Based Learning) results followed.

The 4th batch trainees received AI theory education for two months starting in July and conducted a three-month practical project. The practical project was designed for industrial employees to select and solve real problems occurring on site.

At the graduation ceremony, cases of solving difficulties in production sites using AI learned intensively over five months were presented.

Seoyeon E-Hwa developed an AI model to replace design optimization and crash performance analysis for verifying the performance of automobile parts. Although the company relies on traditional methods, the increasing number of car models and shortened new car development periods demand faster and more diverse parts performance verification.

Applying these results is expected to reduce the parts performance verification period from 15 days to 3 days and save more than 200 million KRW annually.

Hanmac Controls is a small and medium-sized enterprise providing production equipment sensors and factory automation equipment to the manufacturing industry, recently transforming into an intelligent factory solution company by integrating computer vision solutions.

In this project, they developed a computer vision AI model to reduce errors made by workers selecting defective products and found ways to improve the productivity and quality control capabilities of their client companies.

Power MNC is a small and medium-sized enterprise supplying various manufacturing equipment to nuclear power plants and steel mills. Through the project task, they improved the health judgment processor of the ‘Robgap Measuring Device,’ a measurement device provided at steel mills, based on AI.

This is expected to increase data processing time and work efficiency, leading to client retention and new sales.

Korea National Oil Corporation conducted a project to improve the accuracy of well reserve prediction.

Previously, empirical formulas or numerical simulation techniques were used for reserve prediction, but these methods had insufficient accuracy or required large amounts of diverse data and time. To address these shortcomings, they developed an AI model that predicts production using only well data.

Based on this, they expect to improve reserve prediction accuracy and reduce time and costs through future model optimization.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.