Energy Technology Research Institute "High Commercialization Potential"

Simultaneous Decomposition and Purification, Operates at Low Temperature

Expected to Drastically Reduce High-Purity Hydrogen Production Costs

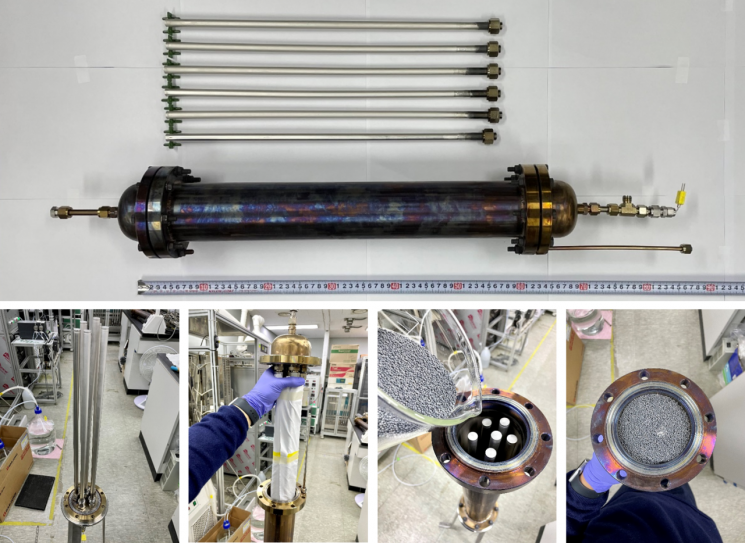

High-purity hydrogen production from ammonia - Palladium composite membrane successfully localized (above) and membrane reactor capable of producing 2 kg of hydrogen per day (below)

High-purity hydrogen production from ammonia - Palladium composite membrane successfully localized (above) and membrane reactor capable of producing 2 kg of hydrogen per day (below)

[Asia Economy Reporter Kim Bong-su] A new technology has been developed that can significantly reduce the cost, energy, and time required for hydrogen production through ammonia.

The Korea Institute of Energy Research announced on the 25th that Dr. Shin Geun Lee and his research team at the High-Temperature Energy Conversion Laboratory have succeeded in producing high-purity hydrogen with over 99.99% purity by developing an integrated membrane reactor capable of decomposing ammonia into hydrogen while simultaneously purifying it.

The newly developed low-temperature catalyst-membrane composite ammonia reforming technology enables the production of green hydrogen from ammonia using a palladium membrane reactor at low temperatures below 500℃. After years of research and development, domestic production has been successfully achieved.

Ammonia is considered a major means of storing and transporting hydrogen, which is recognized as a key renewable energy source. To extract hydrogen from ammonia, a catalytic decomposition method is used. Generally, this reaction decomposes over 95% at temperatures above 400℃, but due to the low activity of commercial catalysts, the temperature must be raised above 600℃ to increase the decomposition rate. Additionally, nitrogen is removed by PSA (Pressure Swing Adsorption) for high-purity production, but due to the limitations of adsorbents that can only adsorb nitrogen, achieving high purity is difficult. Existing reactors for ammonia-based hydrogen extraction are complex systems composed of an ammonia decomposition reactor combined with PSA (Pressure Swing Adsorption) and TSA (Temperature Swing Adsorption) purification technologies.

The research team succeeded in developing an integrated membrane reactor that uses a palladium membrane and ammonia decomposition catalyst to decompose ammonia by more than 98% at temperatures over 100℃ lower than conventional methods while simultaneously purifying the hydrogen. By using a hydrogen separation membrane without PSA or TSA purification technologies, hydrogen production and purification can be performed simultaneously. This simultaneous production and purification of hydrogen lowers the decomposition temperature due to the removal of products in the equilibrium reaction, based on Le Chatelier’s principle, while enabling the production of high-purity hydrogen. According to Le Chatelier’s principle, the membrane reactor continuously removes the product hydrogen, thereby promoting the forward reaction (ammonia decomposition reaction) and allowing high decomposition rates even at low temperatures.

The most important factors in the membrane reactor are the performance and cost of the membrane. The research team overcame the limitations of existing palladium membranes, which were considered expensive and difficult to manufacture densely, by improving the ‘electroless plating method.’ Through this, the amount of palladium used was reduced by more than half, and hydrogen extraction at low temperatures below 500℃ was confirmed.

Experimental results using multiple membranes developed by the research team installed in the reactor demonstrated that even with the reactor temperature lowered by over 100℃, a decomposition rate of 98%, hydrogen recovery rate above 93%, and production of high-purity hydrogen exceeding 99.99% at more than 2 kg/d were verified by an accredited certification body. In particular, the developed membranes have a large area and produce more than twice the amount of hydrogen per unit area compared to existing membranes, ranking among the world’s best. Increasing the number of membranes allows for scaling up hydrogen production, confirming high commercialization potential.

Dr. Lee stated, “The technology to extract hydrogen from ammonia using a membrane reactor integrates the decomposition reaction and hydrogen purification into one process, making it a process-integrated next-generation technology actively researched for several years in advanced countries such as the United States, Australia, Japan, and Europe.” He added, “For technological advancement, Korea also needs significant interest and support for membrane and process integration research.”

The results of this research were published in the prestigious thermodynamics journal ‘ENERGY.’

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)