Research Team of Dr. Jeong Chanhee at the Korea Atomic Energy Research Institute

[Asia Economy Reporter Kim Bong-su] A safe battery manufacturing technology that can completely prevent electrolyte leakage, identified as the cause of electric vehicle battery fires, has been developed in Korea.

On the 13th, the Korea Atomic Energy Research Institute announced that Dr. Jeong Chan-hee's research team at the Advanced Radiation Research Institute developed an 'electron beam-based semi-solid battery manufacturing technology.'

Batteries, essential for electronic devices and electric vehicles, contain liquid electrolytes. The flammable liquid electrolyte can leak outside the battery, causing leakage or fires that may result in greater damage. The research team developed a semi-solid battery manufacturing technology using electron beams that offers the same performance as existing batteries but is safer. A semi-solid battery refers to a battery in which the substance (electrolyte) that transfers lithium ions to the cathode and anode inside the battery is in a gel form (semi-solid).

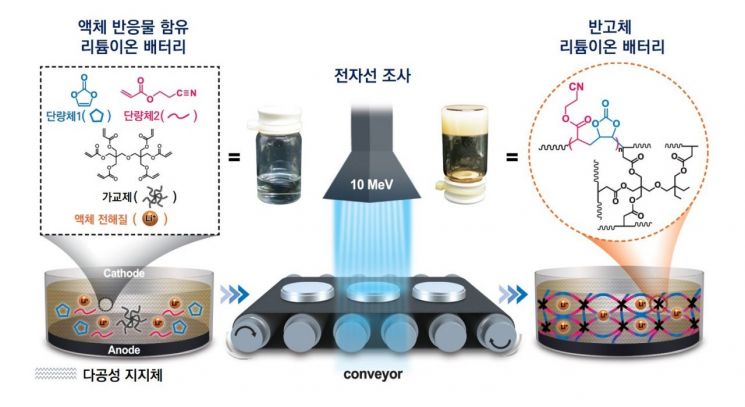

Using the research team's technology, semi-solid batteries can be manufactured with no performance degradation compared to liquid batteries and improved safety against fire and explosion. The team focused on the characteristics of electron beams, which induce chemical reactions at room temperature and have high penetration power to reach inside the battery, and developed an electron beam-responsive reactant that transforms liquid into a semi-solid form when irradiated with electron beams. The reactant developed by the researchers is a mixture of two types of monomers (vinylene carbonate and 2-cyanoethyl acrylate) and a crosslinker added to the existing liquid electrolyte, which turns into a semi-solid upon electron beam irradiation. The liquid electron beam-responsive reactant is filled into the spaces between the cathode, support, and anode inside the battery. When irradiated with a 10 MeV electron beam, the liquid reactant inside the battery transforms into a gel-like semi-solid electrolyte.

Analysis of the cross-section and elemental distribution of the semi-solid battery developed by the researchers confirmed performance at the same level as liquid electrolyte batteries. The semi-solid electrolyte is evenly and tightly formed inside the battery, providing excellent performance while preventing leakage outside in gel form, thereby securing additional safety. Long-term stability evaluation tests comparing discharge capacity changes with existing batteries showed similar results at room temperature and less discharge capacity reduction at 60 ℃, confirming superior high-temperature stability. Furthermore, considering that the manufacturing process only adds an electron beam irradiation step lasting a few minutes to the current commercial lithium battery manufacturing process, commercialization is expected to be highly favorable.

The research results were published online last month on the 23rd in the Chemical Engineering Journal (IF = 16.744), a world-renowned journal in the field of chemical engineering.

Dr. Jeong stated, “This achievement is significant in that it presents a new methodology that adds an electron beam irradiation process to the current battery manufacturing process, enabling simultaneous commercial-level performance improvement and mass production feasibility,” and added, “Based on this, we plan to develop next-generation all-solid-state battery manufacturing technology with enhanced safety.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.