Samsung, TSMC Face 1.4nm Competition Outlook

Success of Ultrafine Process Depends on EUV Equipment

Expansion of Deals with ASML as a Variable

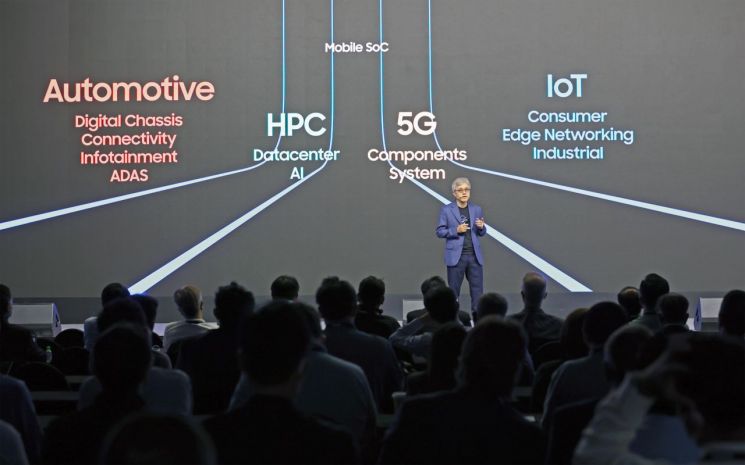

On the 3rd (local time), Choi Si-young, President of Samsung Electronics Foundry Business Division, is seen giving a presentation at the 'Samsung Foundry Forum 2022' held in Silicon Valley, USA.

On the 3rd (local time), Choi Si-young, President of Samsung Electronics Foundry Business Division, is seen giving a presentation at the 'Samsung Foundry Forum 2022' held in Silicon Valley, USA. [Photo by Samsung Electronics]

[Asia Economy Reporter Han Ye-ju] Samsung Electronics, aiming to become the world's No. 1 system semiconductor company by 2030, has made another bold move to catch up with TSMC. That is the 1.4-nanometer (nm; 1 nanometer is one billionth of a meter) process.

The success or failure of the so-called "ultrafine process," which generally refers to processes below 7 nanometers, largely depends on the supply of extreme ultraviolet (EUV) lithography equipment. EUV is a device that allows drawing extremely fine circuits on semiconductor wafers, and these fine circuits are directly linked to semiconductor performance. This is why the Dutch equipment company ASML has attracted attention following Samsung's 1.4-nanometer announcement. To carry out ultrafine processes, it is essential to expand transactions with ASML, which holds a monopoly on EUV supply, and secure even one more EUV machine.

According to industry sources on the 5th, Samsung Electronics held the "Samsung Foundry Forum 2022" in Silicon Valley, USA, and unveiled a roadmap to introduce mass production systems for 2-nanometer by 2025 and 1.4-nanometer by 2027. This is the first time Samsung Electronics has officially announced its 1.4-nanometer mass production plan. If the plan proceeds as scheduled, Samsung will once again surpass its competitor, Taiwan's TSMC, following the 3-nanometer process, to possess the most advanced process technology.

Following Samsung Electronics' 1.4-nanometer declaration, TSMC and Samsung are expected to fiercely compete in the future 1.4-nanometer domain. It is known that TSMC proactively shifted its 3-nanometer process development team to 1.4-nanometer process development this year. Additionally, TSMC is investing an extra $44 billion this year to intensify development of 1- and 2-nanometer technologies.

The reason semiconductor companies compete in ultrafine processes is simply to produce smaller yet higher-performing semiconductors. From the perspective of companies manufacturing and selling semiconductors, producing more semiconductor chips per wafer is essential to maintain product competitiveness. Moreover, semiconductor customers want chips that are smaller, consume less power, and can process information faster.

To draw increasingly finer semiconductor circuits, EUV equipment is indispensable. Using EUV equipment enables the implementation of detailed semiconductor circuit patterns and simplifies the manufacturing process. The problem is that the number of EUV machines produced is extremely limited. ASML manufactures about 40 to 50 units annually, and last year alone produced 42 units, selling 44% to Taiwan and 35% to South Korea. Securing additional EUV machines directly translates to technological capability and production capacity for semiconductor companies.

This is why ASML has earned the nickname "Super Eul (乙)." Typically, equipment suppliers deliver machines to semiconductor manufacturers, but manufacturers compete fiercely to secure even one more EUV machine. CEOs such as C.C. Wei of TSMC and Pat Gelsinger of Intel have personally flown to the Netherlands to plead for equipment. Samsung Electronics Vice Chairman Lee Jae-yong also visited the Netherlands last June to sign contracts for the Hi-Numery EUV equipment scheduled for release next year and lithography equipment produced this year.

Samsung Electronics, led by Vice Chairman Lee Jae-yong, aims to become No. 1 in the system semiconductor sector, including foundry, by 2030. Therefore, a technological gap based on EUV equipment is of utmost importance. Currently, Samsung's foundry market share is stagnant below 20%, due to TSMC's dominance with over 50% market share. Since foundry requires reliable delivery of semiconductors with promised quality on schedule, it is not easy for Samsung, a latecomer, to catch up with TSMC in a short period. Ultimately, Samsung must lead in ultrafine processes to poach TSMC's existing customers.

Not only in system semiconductors but also in memory semiconductors, companies are adopting EUV equipment, deepening semiconductor companies' reliance on ASML. As demands for high-performance, ultra-compact semiconductors increase in DRAM, EUV technology, which can enhance integration density, has become necessary. Currently, Samsung Electronics, SK Hynix, and the US-based Micron have introduced EUV technology in DRAM production.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.