Semiconductor ALD Research Equipment Company CNOne

Top 10 Supplier to World No.1 Semiconductor Equipment Company Applied Materials

Turnaround with Increased New Overseas Orders Despite COVID-19 Slowdown

Selected for 1 Billion KRW Ministry of SMEs and Startups National Project... Developing ALD Equipment for Secondary Battery Raw Material Coating

"Aiming to Become a Global Equipment Company Producing Mass Production Equipment Beyond ALD Research Equipment"

[Asia Economy Reporter Kwak Min-jae] In semiconductor manufacturing processes, coating wafers (substrates) uniformly with special materials is called deposition. Among these, Atomic Layer Deposition (ALD) has recently gained the most attention worldwide amid the global semiconductor nano-competition. To engrave nano-level fine patterns on wafers, the thickness of the deposited film must be thin, and ALD can form films at the atomic scale. Because of this, it is regarded as a technology optimized for Extreme Ultraviolet (EUV) processes compared to conventional deposition equipment. The ALD market is also expected to grow significantly. According to the Technology and Information Promotion Agency for SMEs (TIPA), the domestic ALD market size is projected to grow at an average annual rate of 7.3%, reaching approximately $1.25 billion (1.7 trillion KRW) by 2030.

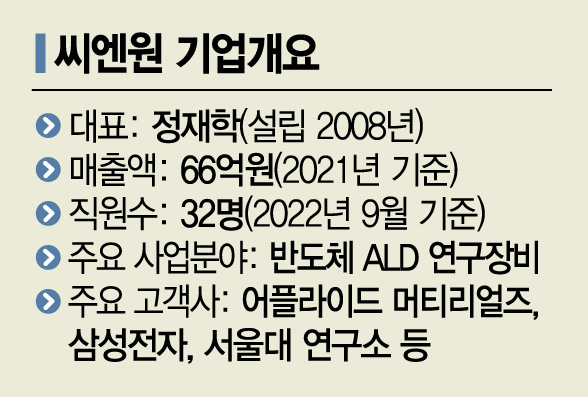

Jung Jae-hak, CEO of CNOne, which produces ALD research equipment, explained, "As semiconductors become finer, introducing ALD research equipment to upgrade existing processes is essential. CNOne is recognized for its technological capabilities in this field, having supplied 10 units of equipment to the research lab of Applied Materials, the world's leading semiconductor equipment company, for the first time domestically."

Turnaround with Increased Overseas Sales... Expected Sales of 8 Billion KRW This Year

CNOne focuses on ALD research equipment as its main product. The reason for demand in research equipment separate from mass production equipment is that mass production equipment consumes too much water, materials, and power due to its nature of large-scale production. In contrast, research equipment has the same technology as mass production equipment but is smaller in size, reducing costs for research and development (R&D). It is also characterized by its applicability to wafers of various sizes such as 12-inch, 8-inch, and 6-inch suitable for different processes. Samsung Electronics, Applied Materials, Seoul National University, and other domestic university research institutes also use CNOne’s products. CNOne holds a 30-40% market share in the domestic ALD research equipment sector, leading the industry.

The core of the company's ALD equipment lies in enhancing the performance of the showerhead, a device that evenly sprays materials, and designing equipment to easily control the process to form uniform thin films. The company states that it holds 12 related patents. CNOne independently develops the hardware and software necessary for ALD facilities using proprietary technology. CEO Jung said, "Based on proprietary technology and accumulated data, we can monitor in real-time whether the thickness and material coating are uniform when manufacturing chips such as memory semiconductors or system semiconductors, as well as any safety issues occurring in the equipment, earning the trust of our clients."

Due to the impact of COVID-19, sales decreased from 7.5 billion KRW in 2020 to 6.6 billion KRW last year. However, with consecutive overseas orders this year and improving performance, sales are expected to reach 8 billion KRW, marking a turnaround. CNOne successfully supplied one unit of ALD equipment each to Merck, a global German chemical company, and a U.S. secondary battery material company. Although the supply scale is not large, the price per ALD equipment ranges from $750,000 (about 1 billion KRW) to $1.2 million (about 1.7 billion KRW), which is sufficient to improve performance, according to the company. As the COVID-19 situation improves, the overseas export ratio, currently at 30%, is expected to increase to 40% next year.

Targeting New Businesses Such as Secondary Battery Material Coating... Groundbreaking of Second Factory in Yongin

CEO Jung worked for seven years in research positions at foreign semiconductor equipment companies before founding the current company. At that time, he saw Samsung Electronics' interest in ALD equipment to narrow semiconductor design rules (circuit linewidth) as a business opportunity.

CNOne views secondary battery material coating equipment as a future new business. ALD equipment is needed to apply specific materials in fields other than semiconductor wafers. In particular, technology to coat anode and cathode raw materials of secondary batteries with ALD equipment to improve battery efficiency and extend lifespan is gaining attention. According to the industry, this technology is currently in pilot production and is expected to be introduced into full-scale mass production processes in 2024.

To target the secondary battery market, the company is also focusing on technology development. It invests 10% of its annual sales in R&D. Last year, it was selected for a national project by the Ministry of SMEs and Startups and received 1 billion KRW in support to complete the development of secondary battery material coating equipment by next year. CNOne is also constructing a second factory in Yongin with an investment of about 15 billion KRW to establish a new research and production line. The total area is 9,917㎡. CEO Jung stated, "ALD equipment, which is gaining attention in semiconductors, has limitless application fields including secondary batteries, OLED displays, and bio. We aim to grow into a global comprehensive equipment company producing mass production equipment for various application fields beyond semiconductor ALD research equipment."

Hwaseong, Gyeonggi Province = Reporter Kwak Min-jae

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.