Direct Production of Anode Material Intermediates Previously Fully Imported

Establishing a Stable Supply System

[Asia Economy Reporter Choi Seoyoon] POSCO Chemical is partnering with OCI to localize the production of pitch, an intermediate material for battery anode materials. The goal is to directly produce a material that was previously fully imported and to complete the entire value chain from anode raw materials and intermediate materials to final products, thereby securing a solid competitive advantage in the global battery materials market.

POSCO Chemical and OCI’s joint venture, P&OChemical, held a groundbreaking ceremony for the pitch factory on the 21st at the Tancheon Industrial Complex in Gongju, Chungnam Province. Attendees included Kim Juhyun, Head of Planning and Support at POSCO Chemical; Kim Yushin, Vice President of OCI; Kim Jongguk, President of P&OChemical; and Choi Woncheol, Mayor of Gongju.

P&OChemical plans to invest 96.3 billion KRW to complete a pitch factory for anode coating with an annual capacity of 15,000 tons by 2023. Pitch is a carbon material produced by refining coal or petroleum and is used for surface coating of anode materials and as a binder in aluminum smelting processes.

For anode coating, a petroleum-based high softening point pitch, which has a higher melting point than general pitch, is used. This material significantly affects performance by increasing battery charge-discharge speed and extending battery life. China and Germany are major producers, making localization of this material essential.

POSCO Chemical, the only domestic company producing both anode and cathode materials, will be able to stably supply high-quality customized anode intermediate materials once the pitch factory is built. According to industry sources, global demand for anode pitch is expected to reach about 150,000 tons by 2025, with demand surging alongside the growth of the battery industry. P&OChemical plans to prioritize supplying products for POSCO Chemical’s anode materials and also sell them in the global market.

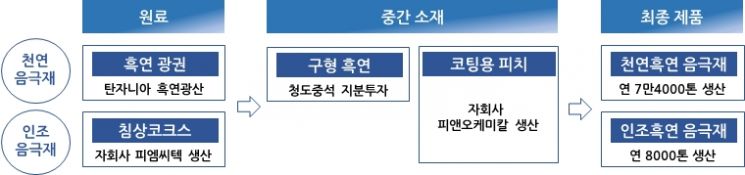

Additionally, by completing the entire anode material business value chain?from raw materials to intermediate materials to product manufacturing?business competitiveness will be enhanced. POSCO Chemical secured natural graphite through POSCO Group’s investment in mining rights in Tanzania and artificial graphite through its subsidiary PMC Tech’s production of needle coke. For the intermediate material, spherical graphite, it established a supply chain through equity investment in Qingdao Zhongse in China and internalizing pitch production. This system enables mass production of both natural and artificial graphite anode materials as final products.

At the groundbreaking ceremony, Kim Juhyun, Head of Planning and Support at POSCO Chemical, said, “Through cooperation with OCI, we have localized pitch for anode coating, contributing to strengthening the competitiveness of Korea’s battery industry. We will further expand cooperation between the two companies in the high value-added advanced materials sector and secure growth engines.”

OCI is the world’s largest manufacturer of liquid pitch, currently producing 530,000 tons annually, and holds the only pitch production technology in Korea. OCI expects that with this factory construction, it will expand its business area from coal-based liquid pitch, which uses byproducts from steelmaking processes, to high value-added advanced materials such as petroleum-based high softening point pitch used for battery materials, thereby broadening its profit base.

Kim Yushin, Vice President of OCI, stated, “Through cooperation with POSCO Chemical, we have expanded our business into the high value-added electronic materials sector and secured growth momentum. We will strive to achieve the first localization of high softening point pitch, an essential material for secondary batteries, to contribute to strengthening the competitiveness of the domestic secondary battery industry.”

P&OChemical was established in July 2020 as a joint venture with POSCO Chemical holding 51% and OCI 49%. It is promoting advanced materials businesses such as ultra-high purity hydrogen peroxide for semiconductor process materials and pitch for anode materials. The two companies plan to continue pursuing various high value-added materials businesses based on raw materials and technological competitiveness.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)