Next-Generation Nuclear Power Sodium-Cooled Fast Reactor

Operates Using 'Molten Salt' Fuel

Enhances Safety and Dramatically Reduces Waste

SK Group invested 300 billion KRW in TerraPower, a small modular reactor developer founded by Bill Gates, the founder of Microsoft. / Photo by Song Hyundo, Asia Economy intern reporter

SK Group invested 300 billion KRW in TerraPower, a small modular reactor developer founded by Bill Gates, the founder of Microsoft. / Photo by Song Hyundo, Asia Economy intern reporter

[Asia Economy Reporter Lim Juhyung, Intern Reporter Song Hyundo] SK Group recently invested 300 billion KRW in Terrafar, a small modular reactor developer founded by Bill Gates, the founder of Microsoft (MS). Domestic companies have also entered the competition to develop small modular reactors, which are key power sources in the 'carbon-neutral era.' In particular, Terrafar is developing a new concept reactor that uses 'molten salt' as both fuel and coolant, and if commercialized successfully, it is considered a 'game changer' that can solve the nuclear waste problem of nuclear power plants at once.

◆ Bill Gates partners with SK... Developing next-generation reactors

SK announced on the 15th that it has completed a 300 billion KRW equity investment in Terrafar through its energy and chemical intermediate holding company, SK Innovation. The total investment raised by Terrafar amounts to 750 million USD (approximately 986 billion KRW), with SK's investment accounting for about one-third of this. Terrafar plans to accelerate the design of the next-generation reactor, the Sodium-cooled Fast Reactor (SFR), using the secured funds, and SK will participate in the commercialization of this product.

Terrafar was established by Gates in 2008 with an investment of about 35 million USD. Terrafar has been focusing on designing the SFR, which uses thorium and 'molten salt' as fuel instead of uranium. Although the maximum power output of SFR is about 2 to 3 times lower than that of conventional nuclear power plants, it is inexpensive, safe, and can drastically reduce the amount of nuclear waste after power generation.

◆ 'Molten salt' nuclear fuel is key

Although the English translation of 용융염 is 'molten salt,' it is not edible salt. It is a substance made by mixing sodium nitrate and potassium nitrate and heating it to a liquid state at temperatures between 260 and 550 degrees Celsius.

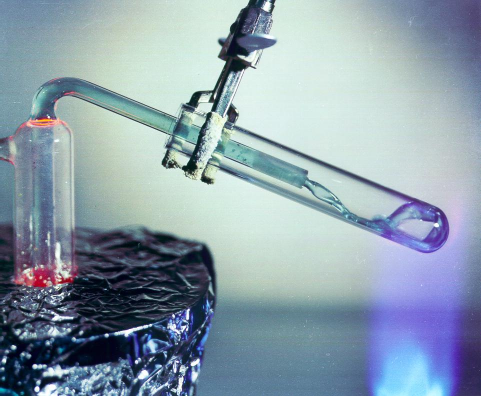

Molten salt, translated as '녹인 소금', refers to a substance made by heating salt to a liquid state. It is considered a fuel and coolant for next-generation nuclear power plants. / Photo by Wikipedia

Molten salt, translated as '녹인 소금', refers to a substance made by heating salt to a liquid state. It is considered a fuel and coolant for next-generation nuclear power plants. / Photo by Wikipedia

The advantage of molten salt is that it is easy to handle. It has a high boiling point, so it does not evaporate even if the reactor becomes hot, and it solidifies when exposed to the atmosphere. Even if an accident occurs during reactor operation, it means that no toxic gases will leak or core meltdown (damage to the reactor structure caused by hot nuclear fuel) will occur. Nuclear waste is also reported to be reduced by up to 95% compared to existing nuclear power plants.

Although it may seem like a 'dream reactor,' its fatal drawback is economic feasibility. Compared to the most common pressurized water reactor (PWR) type reactors today, the manufacturing cost is very high, and the core coolant, sodium, is difficult to handle.

The Korea Atomic Energy Research Institute has also been developing SFR for decades and holds many related design technologies, but research is conducted only for auxiliary purposes such as recycling spent nuclear fuel from existing nuclear power plants, not for power generation.

◆ Fierce competition in the small modular reactor market

Terrafar, supported by SK, plans to build an SFR prototype in the small city of Kemmerer, Wyoming, USA. The construction period is from 2024 to 2031, lasting seven years.

Although Terrafar has taken the first step, numerous companies from global conglomerates to startups are entering the small modular reactor development market, making competition fierce.

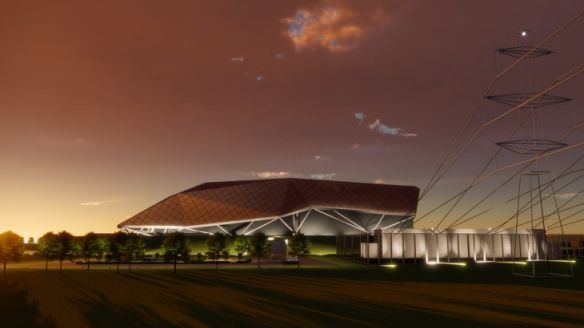

Expected image of Rolls-Royce's next-generation small nuclear reactor by the British engineering company Rolls-Royce / Photo by Rolls-Royce

Expected image of Rolls-Royce's next-generation small nuclear reactor by the British engineering company Rolls-Royce / Photo by Rolls-Royce

The company currently most advanced in the prototype construction stage is Rolls-Royce, the world's second-largest aircraft engine manufacturer based in the UK, which has set a goal to build 16 pressurized water small modular reactors within the next 25 years. This company's reactors are already under review by the UK regulatory authorities, and six factory sites for future reactor manufacturing have been selected.

Another small modular reactor startup, NuScale, has received reactor design certification from the U.S. Nuclear Regulatory Commission (NRC). The company announced in June last year that it would shift its management strategy from 'product development' to 'product delivery' and plans to build the first commercial reactor at the Idaho National Laboratory site in the United States.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.