Display 'Edge Grinder' Equipment Global Market Share 70% Leading Company

Supplies 'Wafer Processing Equipment' to Major Domestic Semiconductor Manufacturers' New Process Lines

Participating in National Project for 'Dream Secondary Battery' All-Solid-State Battery Equipment for 2 Years

Commercializing Laparoscopic Surgical Robots, Aiming to Become a Global Comprehensive Equipment Company

[Asia Economy Reporter Kwak Min-jae] "We have completed preparations to ride the new industries of semiconductors and secondary batteries with products utilizing nearly 30 years of accumulated display processing technology."

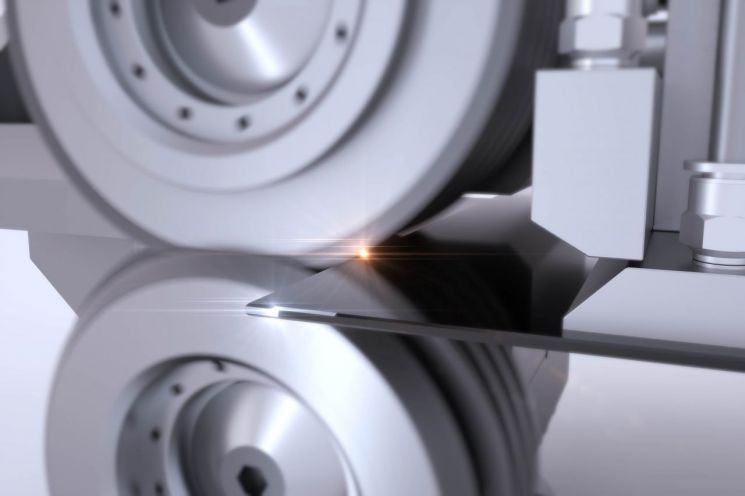

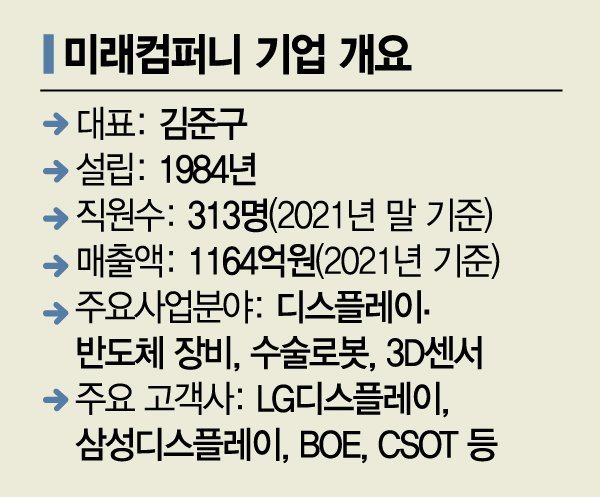

Kim Jun-gu, CEO of Mirae Company, the world's No.1 producer of display process equipment 'Edge Grinder,' spoke about the company's new growth engine. Mirae Company is the first company to domestically produce the edge grinder, a display panel processing device. It is essential equipment used in the display production process because it increases the panel's durability by 50%. Mirae Company's edge grinder holds a 70% share of the global market, ranking first worldwide. Major clients include LG Display, Samsung Display, and China's BOE and CSOT.

◆ Supplying semiconductor wafer processing equipment... also targeting all-solid-state battery equipment = In March last year, Mirae Company passed quality certification tests from major domestic clients and completed initial delivery of wafer processing equipment to a new semiconductor process line. Typically, the semiconductor wafer manufacturing process is a main process requiring high precision and security, making it very difficult for new companies to enter. The export restrictions imposed by Japan three years ago became a turning point. At that time, domestic semiconductor manufacturers requested equipment necessary for the new process from Japanese companies to increase semiconductor integration density, but no company was willing to develop new equipment. Mirae Company seized the opportunity and succeeded in developing wafer processing equipment needed for the new process. CEO Kim said, "Based on edge grinder technology that precisely controls and processes display panel cut surfaces at the micrometer (㎛) level using diamond wheels, we achieved the feat of delivering equipment for the wafer new process in just three years."

They are also targeting secondary battery processing equipment. In 2019, they succeeded in developing equipment that processes cooling plates that wrap secondary battery cells. This part requires technical skill because improper processing can cause differences in thermal conductivity, affecting battery life. For the past two years, they have participated in a national project led by the Ministry of Trade, Industry and Energy and Samsung SDI for all-solid-state battery cell pressing and inspection equipment. All-solid-state batteries replace the liquid electrolyte between the battery's anode and cathode with a solid and eliminate the separator, making them next-generation batteries. They are called the "dream secondary battery" because they can improve safety and energy density compared to conventional lithium-ion batteries. CEO Kim said, "We completed a dry room at Mirae Company's Hwaseong headquarters research center and are currently conducting production line tests for equipment used to stack, press, and perform nondestructive inspection of solid electrolytes between the pre-process and deposition process."

Mirae Company succeeded in a turnaround last year. Due to a significant reduction in facility investment in the display industry caused by COVID-19, Mirae Company's sales fell to 58.9 billion KRW in 2020, but last year sales doubled, achieving profitability. Last year's sales were 116.4 billion KRW, with an operating profit of 4.6 billion KRW. CEO Kim explained, "As the COVID-19 situation gradually improves, demand for equipment in the display industry is also increasing," adding, "In the long term, instead of the highly volatile display equipment business, we plan to diversify our portfolio into the less volatile semiconductor and all-solid-state battery equipment businesses."

◆ Stepped in as a savior during management crisis... also developing laparoscopic surgical robots = Mirae Company was established in 1984. CEO Kim is the son of the late founder Kim Jong-in. He earned bachelor's and master's degrees in engineering from Cornell University and completed an MBA at the University of Chicago. After working as a senior researcher at Samsung Electronics' Information and Communication Division's Communication Research Lab, he worked at global consulting firm Bain & Company. When his father suddenly passed away in June 2013, Kim joined Mirae Company in 2014. At that time, the company's situation was not good. Sales in 2014 were 44.8 billion KRW, halved from before, and the company recorded losses for two consecutive years. This became the turning point for CEO Kim to devote himself to technology development and nurturing new businesses.

Mirae Company is also focusing on surgical robots as its next-generation growth engine. It commercialized the laparoscopic surgical robot as the second in the world. From 2007, it invested 40 billion KRW in research and development over 11 years and launched the laparoscopic surgical robot Revo-i in 2018. The laparoscopic surgical robot supports and performs surgical operations. Clinical data on various indications were accumulated at Severance Hospital, and approval was obtained from the Ministry of Food and Drug Safety. After development, Revo-i was supplied to specialized hospitals, and in November last year, it was introduced to the Nuclear Hospital, a general hospital-level public medical institution. Additionally, certification work for dealership contracts is underway not only in the domestic medical market but also in overseas markets such as Southeast Asia, the Middle East, and Russia. CEO Kim said, "Mirae Company's driving force is that once we are confident in a market, we do not hesitate to invest until results are achieved," adding, "Based on more than 50% of our workforce being researchers, we consistently invest about 10% of sales in technology development to become a 'global comprehensive equipment company.'"

Gyeonggi Yongin = Reporter Kwak Min-jae

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.