First Domestic Production of Pad Conditioner Previously Fully Imported

Diamond Etching and Reverse Deposition Method... Conditioner Performance Improved by 50%

Semiconductor Companies Expand Facilities... Conditioner Orders Increase

Last Year's Sales Up 20% to 123.9 Billion KRW

Targeting 50% Market Share Within 3 Years

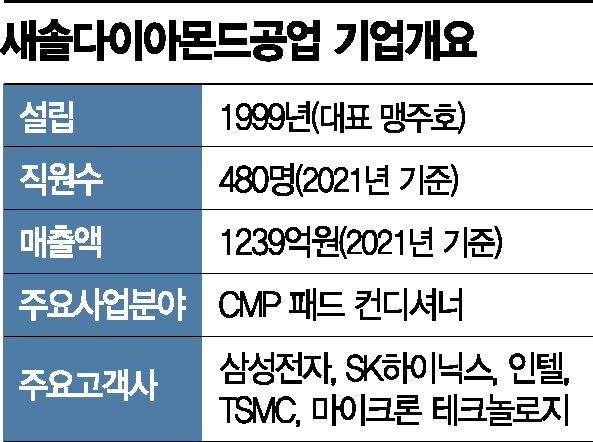

[Asia Economy Reporter Kwak Min-jae] Global semiconductor giants such as Samsung Electronics, SK Hynix, TSMC, Intel, and Micron Technology use this company's products. To make the surface of wafers, the main raw material of semiconductors, flat (semiconductor CMP process), a component called a pad is used, and to continuously maintain the polishing power of the pad, Saesolda Diamond Industry's ‘CMP Pad Conditioner’ is essential. The uniform roughness characteristics of the pad surface directly affect semiconductor yield (the ratio of defect-free qualified products) and quality. If a problem occurs with the CMP pad conditioner, wafers worth tens of millions of won each can be damaged, so companies have no choice but to select products carefully.

Saesolda Diamond Industry, a specialist company in CMP pad conditioners, CEO Maeng Ju-ho said, "Our company is the first to domestically produce pad conditioners that were previously entirely imported from overseas due to lack of technology in Korea," adding, "We hold a 35% share of the global pad conditioner market, ranking first worldwide."

◆ 50% Performance Improvement Compared to Competitors... Sales Increase Due to Semiconductor Shortage = Saesolda Diamond Industry's CMP pad conditioner accounts for 99% of the company's total sales. There are six types and a total of about 270 products. Saesolda Diamond Industry improved the performance of pad conditioners by 50% compared to competitors through an etching method that makes the arrangement and shape of diamonds used in pad conditioners uniform and a reverse plating method that keeps the height consistent. The company explains that it solved the problem of diamonds falling out during the pad polishing process and damaging wafers, reducing the defect rate in the CMP process by more than half.

More than 20 years of experience supplying pad conditioners to large corporations is also a competitive advantage of Saesolda Diamond Industry. CEO Maeng said, "As semiconductors become finer and more integrated, pads and slurry (semiconductor polishing agents) used in the CMP process continue to change," adding, "Constantly developing pad conditioners to meet changed processes and components and satisfying customer needs is something that can only be achieved through long experience and accumulated references."

Exports account for more than half (65%) of sales composition. Last year, sales reached 123.9 billion won, and operating profit was 27.6 billion won. Sales increased by 20% compared to the same period last year. The increase in sales was due to global semiconductor companies expanding production facilities, which led to a rise in conditioner orders. The global pad conditioner market size is about 350 billion won. CEO Maeng explained, "Our mass production capacity to produce more than 120,000 conditioners per month and systematic quality control through diamond raw material selection and inspection have led to increased orders from global semiconductor companies."

◆ Increased Productivity Through Smart Factory... Achieving 50% Global Market Share = CEO Maeng worked at Ewha Diamond Industry for three years before leaving to found Saesolda Diamond Industry in 1999. While the 1997 foreign exchange crisis was harsh for most domestic companies, it became a turning point for Saesolda Diamond Industry. The price of pad conditioners, which had been entirely imported, surged about 2.5 times from 700,000 won to 1.8 million won per unit due to the sharp rise in foreign currency, prompting domestic large companies to take an interest in domestic production of conditioners. Saesolda Diamond Industry seized the opportunity and succeeded in domestic production of pad conditioners after two years of development, supplying both Samsung Electronics and Hyundai Electronics (now SK Hynix).

Saesolda Diamond Industry began introducing smart factories and automation systems last year. As technological capabilities in countries like China rapidly improve, competition is intensifying. Automation systems have been introduced in the first, second, and third factories located in Ansan, Gyeonggi Province, to increase productivity, and plans are in place to further enhance quality and stability through a quality assurance system. In particular, the company plans to raise its market share of pad conditioners in the non-memory sector, which requires high precision, to 35% within three years. Currently, the market share in the non-memory sector is 11%. CEO Maeng stated, "To firmly maintain our position as the world's number one pad conditioner company, we invest about 5% of annual sales in research and development (R&D). We aim to increase our global market share from the current 35% to 50% within three years and achieve sales of 200 billion won."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

!["The Woman Who Threw Herself into the Water Clutching a Stolen Dior Bag"...A Grotesque Success Story That Shakes the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)