KIST Research Team Develops Steel 100 Times Stronger at One-Quarter the Weight

[Asia Economy Reporter Kim Bong-su] A core material for the ‘space elevator,’ which connects the Earth's surface to space bases and can transport people and supplies much more cheaply than rockets, has been developed by domestic researchers. This new material is over 100 times stronger than steel yet more than four times lighter, attracting attention as a dream material not only for space elevators but also for space, defense, and aviation sectors.

The Korea Institute of Science and Technology (KIST) announced on the 3rd that Dr. Boncheol Koo’s research team at the Carbon Convergence Materials Research Center, in collaboration with Professor Seongwoo Ryu of Suwon University and Dr. Villatella’s team at the IMDEA Materials Institute in Spain, developed an ultra-high-strength and ultra-high-elasticity carbon nanotube fiber material.

Carbon nanotubes possess ultra-lightweight, ultra-high strength, electrical conductivity comparable to copper, and thermal conductivity comparable to diamond. However, when carbon nanotubes have been spun into fibers, the contact area between adjacent nanotubes is low, and their short length causes deterioration in physical properties, limiting widespread use. Existing polyacrylonitrile (PAN)-based carbon fibers have high strength but low elastic modulus, while pitch-based carbon fibers have higher elastic modulus than strength. Research to simultaneously improve carbon fiber strength and elastic modulus has focused on adding only about 1% of carbon nanotubes.

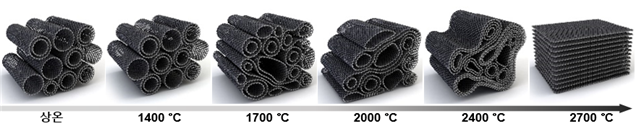

Schematic diagram of the morphological changes of carbon nanotubes according to heat treatment temperature.

Schematic diagram of the morphological changes of carbon nanotubes according to heat treatment temperature.

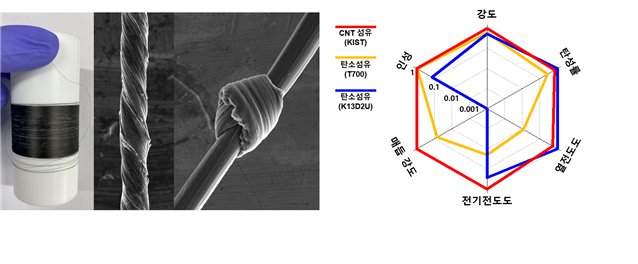

In contrast, the research team succeeded in manufacturing carbon nanotube-only fibers without using conventional carbon fiber precursors such as polymers or pitch. They produced high-density, highly aligned carbon nanotube fibers through a wet spinning process suitable for mass production. By heat-treating at high temperatures, the fibers were transformed into various unique structures including graphite structures, increasing the contact area between carbon nanotubes. The resulting carbon nanotube fibers simultaneously exhibit ultra-high strength (6.57 GPa) and ultra-high elasticity (629 GPa), along with enhanced knot strength indicating flexibility, promising numerous applications.

Dr. Koo stated, “As a latecomer in the carbon fiber field, South Korea can lead this sector using carbon nanotube materials with K-carbon fiber manufacturing technology, creating future growth engines for the space, defense, and aviation industries and advancing into a materials powerhouse.” He added, “We have secured the core technology for manufacturing ultra-high-strength and ultra-high-elasticity carbon nanotube-based carbon fibers, but mass production of double-walled carbon nanotubes, a key material, must be established to enable large-scale production of ultra-high-performance carbon fibers.”

The research results were published in the latest issue of the international journal Science Advances (IF: 14.14, JCR 6.25%).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)