GIST Achieves Success in Fabricating Next-Generation Large-Area Solar Cells Over 500㎠

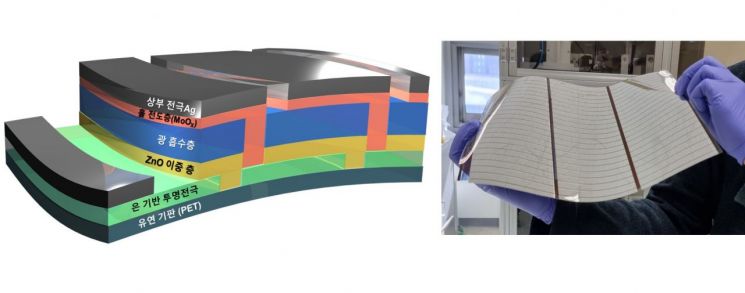

Schematic diagram of large-area flexible organic solar cell module structure (left) and actual photo (right). Photo by GIST

Schematic diagram of large-area flexible organic solar cell module structure (left) and actual photo (right). Photo by GIST

[Asia Economy Reporter Kim Bong-su] Domestic researchers have taken another step closer to the commercialization of next-generation solar cells that generate electricity with high efficiency even when bent. They succeeded in producing a high-efficiency large-area module film that contributes to the commercialization of ‘organic solar cells,’ the next-generation solar cells that will replace conventional silicon solar cells. This research achievement is evaluated as one that overcomes the existing limitation of efficiency decreasing as the film size increases and accelerates the commercialization of large-area flexible organic solar cells.

The research team led by Dr. Kang Hong-gyu and Professor Lee Kwang-hee at Gwangju Institute of Science and Technology (GIST) announced on the 28th that they developed a technology to produce high-efficiency organic solar cell module films larger than 500㎠ on a flexible transparent electrode substrate.

Most existing organic solar cell research has been conducted at the small cell unit level fabricated on expensive and rigid indium tin oxide (ITO) transparent electrode glass substrates (about 1㎠). Although there has been some research on large-area flexible modules, as the module size increases and becomes more flexible, the module efficiency drops significantly, posing challenges for commercialization.

The research team discovered that the hydrophobic surface characteristics of flexible transparent electrode films without rare earth indium cause non-uniformity in the nano-thin films of solar cell materials because the solution does not spread well. To solve this, they introduced a hydrophilic oxide layer to greatly improve surface wettability, thereby forming a uniform large-area nano-thin film.

The module film produced by the research team showed an efficiency of 7.67% at a size of 528㎠. This is the first reported case in academia of a printed flexible organic solar cell module film larger than 500㎠.

Dr. Kang said, “This research is significant in that it solved the biggest obstacle to the commercialization of organic solar cells?the non-uniformity of nano-thin films of solar cell materials?and realized a flexible large-area module with a high level of energy conversion efficiency.” He added, “We plan to promote the commercialization of organic solar cells, which can be applied in film form to various applications without separate land, to accelerate the spread of resident-friendly solar cells.”

The research results were published online on the 16th in ‘Advanced Energy Materials (IF: 29.368),’ a journal ranked in the top approximately 4% in the field of Energy & Fuels.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.