Korea Atomic Energy Research Institute

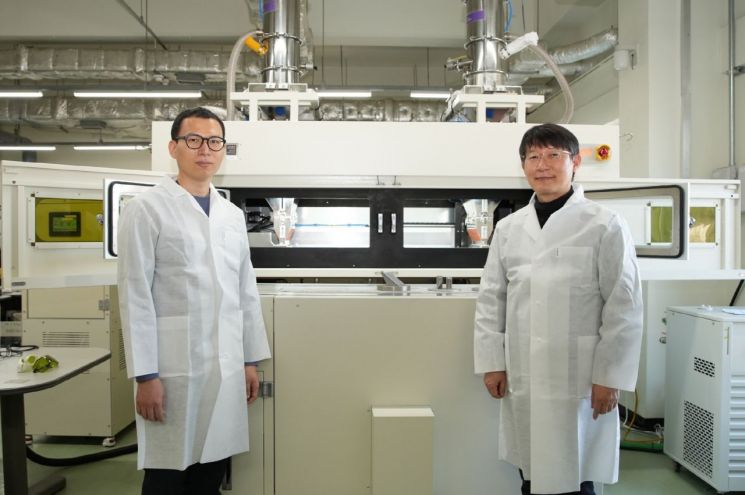

Korea Atomic Energy Research Institute has developed the world's first 3D printer for manufacturing 1m parts using the PBF method. (From left) Seongwook Lee, Senior Researcher, Nuclear Fuel Safety Research Division, Hyungil Kim, Manager. Photo by Korea Atomic Energy Research Institute

Korea Atomic Energy Research Institute has developed the world's first 3D printer for manufacturing 1m parts using the PBF method. (From left) Seongwook Lee, Senior Researcher, Nuclear Fuel Safety Research Division, Hyungil Kim, Manager. Photo by Korea Atomic Energy Research Institute

[Asia Economy Reporter Kim Bong-su] Domestic researchers have developed 3D printing equipment capable of producing large parts measuring 1 meter in size.

On the 24th, the Korea Atomic Energy Research Institute announced that it had developed the world's first 'PBF (Powder Bed Fusion) 3D printer for manufacturing 1-meter-sized parts.' This is a manufacturing technology that prints three-dimensional objects based on 3D drawings. By combining nuclear technology with 3D printing technology, complex structural parts can be designed and manufactured seamlessly, enhancing safety.

The PBF (Powder Bed Fusion) method involves precisely irradiating a thinly spread powder layer with a laser or electron beam to melt and form parts. The melted powder solidifies and can be stacked layer by layer. This principle is advantageous for producing precise parts with complex shapes and is known today as the most common metal 3D printing technology. The problem was that the maximum part size producible with PBF equipment was only up to 0.5 meters, limiting its use in industrial fields.

The research team succeeded in producing a printer capable of manufacturing parts up to 1 meter wide and 0.5 meters long. To eliminate the size limitation of PBF 3D printing, they devised a 'parallel expansion technology.' Two sets of laser sources and scanners, the core components of the printer, were connected side by side. A laser source fixed in one place passes through a scanner with mirror-like reflective properties, evenly delivering light over an area of 0.5 meters by 0.5 meters. In this printer, two laser sources and two scanners are installed respectively, extending the usable range to 1 meter horizontally.

They also succeeded in precisely controlling the overlapping area of the two lasers to maintain high accuracy. By establishing variable values for laser speed and patterns, they can predict deformation caused by heat and stress in advance, enabling the connection parts to be made smoothly without defects.

The research team is preparing to file a patent for this printer. Additionally, since laser sources and scanners can be further connected by 0.5 meters in both horizontal and vertical directions, they expect that developing a 'printer for manufacturing parts several meters in size' will be possible in the future. They have successfully manufactured five prototypes made of nickel alloy materials, such as nuclear power plant heat exchangers and impellers. Going forward, they plan to further advance the large-scale PBF 3D printer technology to provide customized processes and quality certification for each part. In particular, they are focusing on reverse engineering by scanning and manufacturing discontinued parts, as well as developing and manufacturing core components for innovative small modular reactors (i-SMR) and ultra-small reactors for space applications.

Park Won-seon, director of the Korea Atomic Energy Research Institute, stated, “Overcoming the manufacturing limitations of this PBF 3D printer is a pioneering technological innovation achievement of the institute,” and added, “We expect that this technology will be applicable not only to advanced nuclear technology but also to the manufacturing of large parts in other industries such as energy, environment, defense, and space.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.