From 3 Steps to 1 Step, 99.9% Accuracy Similarity

A research team led by Professor Han-Kwon Lim of the Department of Energy and Chemical Engineering at Ulsan National Institute of Science and Technology (UNIST) has developed a performance prediction model for hydrogen production processes incorporating machine learning. (From left: Professor Han-Kwon Lim, Researcher Seung-Hyun Cheon, Researcher Man-Hee Byun, Researcher Chang-Kwon Choi)

A research team led by Professor Han-Kwon Lim of the Department of Energy and Chemical Engineering at Ulsan National Institute of Science and Technology (UNIST) has developed a performance prediction model for hydrogen production processes incorporating machine learning. (From left: Professor Han-Kwon Lim, Researcher Seung-Hyun Cheon, Researcher Man-Hee Byun, Researcher Chang-Kwon Choi)

[Asia Economy Yeongnam Reporting Headquarters Reporter Lee Seryeong] A model that comprehensively predicts and evaluates the performance of hydrogen production processes by combining simulation technology with artificial intelligence has been developed.

Just as one can simulate a building to be constructed in 3D, it has become possible to run process simulations using simulation programs when building large chemical plants.

The research team led by Professor Lim Hangwon of the Department of Energy and Chemical Engineering at Ulsan National Institute of Science and Technology (UNIST) developed a predictive model incorporating machine learning, a branch of artificial intelligence.

This model can simultaneously predict technical performance such as yield, production costs, and carbon dioxide emissions.

Previously, performance was estimated through a complex three-step process, but when the research team evaluated the performance of next-generation hydrogen production processes using the developed model, results were up to 99.9% similar to those from the three-step evaluation method.

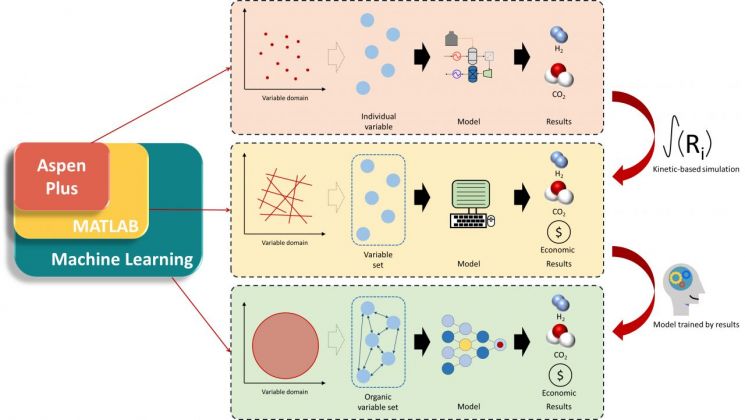

A schematic diagram of the machine learning-based regression prediction model devised in this study.

A schematic diagram of the machine learning-based regression prediction model devised in this study.

The research team applied this predictive model to evaluate the performance of a newly designed methanol wet reforming process.

Methanol wet reforming is a method of obtaining hydrogen by reacting methanol with steam at high temperatures, which emits less carbon dioxide than the widely used steam methane reforming method.

Although the methanol wet reforming process produces less carbon dioxide and consumes less energy, an additional purification process is required to separately separate hydrogen.

To address this, the research team designed a new process integrating a hydrogen-permeable membrane and then examined the process performance using the predictive model.

First, the improved process was designed using a commercial chemical process simulation program, then this process was expressed as equations in a numerical analysis program, and based on the obtained data, a predictive model was completed using a machine learning-based regression algorithm.

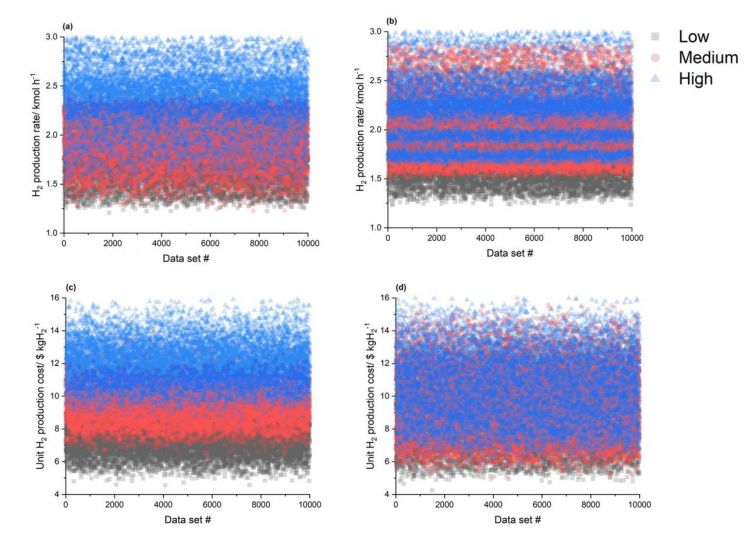

The predictive model evaluated the designed process by varying 12 technical and economic factors such as reaction temperature and labor costs.

The hydrogen production and carbon dioxide emissions of the process were 4.52?5.99 kg and 4.13?6.62 kg per hour, respectively, and the hydrogen production cost ranged from $4.31 to $13.15 per kg.

Compared to results evaluated by the conventional three-step method, the prediction accuracy was 99%, 99.9%, and 96%, respectively.

This research was supported by the Ministry of Science and ICT through the National Research Foundation of Korea (NRF) under the Hydrogen Energy Innovation Technology Development Project and the Climate Change Response Technology Development Project, and was published in the international academic journal Chemical Engineering Journal in December last year.

First author Researcher Byun Manhee stated, “This study revealed that among the 12 technical and economic factors, the number of reactors, reaction temperature, methanol raw material price, and labor costs are the most important for the performance of the process,” adding, “Adjusting these factors according to the purpose of process operation will create a more effective hydrogen production process.”

Professor Lim Hangwon said, “Although there are many cases recently of applying artificial intelligence and machine learning technologies to materials or pharmaceutical development, it is rare to apply them to large-scale chemical process technologies,” and added, “Using accumulated process operation data will further improve the prediction accuracy of this model.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)