KIST Research Team

[Asia Economy Reporter Kim Bong-su] Research and development of next-generation battery technology, all-solid-state batteries, is underway to reduce the risk of explosion and fire in lithium-ion batteries. Domestic researchers have developed a high-performance solid electrolyte that can replace the existing liquid electrolyte, marking significant progress toward the commercialization of all-solid-state batteries.

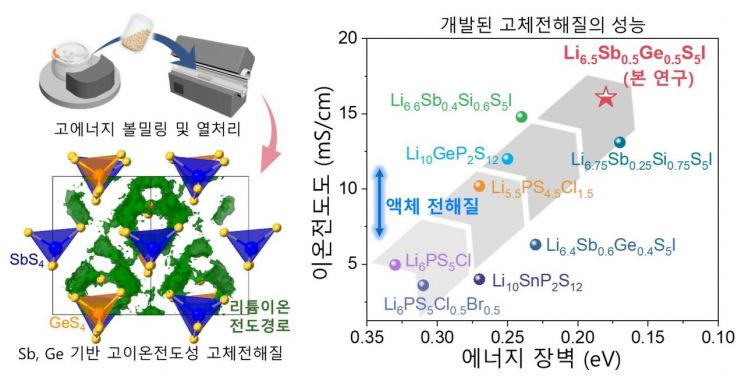

The Korea Institute of Science and Technology (KIST) announced on the 19th that Dr. Seungho Ryu's research team at the Energy Storage Research Center optimized the materials and synthesis process of sulfide-based solid electrolytes and developed a high ionic conductivity solid electrolyte comparable to the ionic conductivity of liquid electrolytes.

While various candidate solid electrolytes for lithium all-solid-state batteries with ionic conductivities comparable to liquid electrolytes are being reported one after another, sulfide-based solid electrolytes show relatively high ionic conductivity, prompting research to improve materials and synthesis processes. The problem is that sulfide-based solid electrolytes react with moisture when exposed to air, producing toxic hydrogen sulfide (H2S) gas.

The research team developed a high ionic conductivity solid electrolyte with 16.1 mS/cm by introducing antimony (Sb) and germanium (Ge) into the argyrodite solid electrolyte material, one of the high ionic conductivity sulfide-based solid electrolytes, and inserting additional lithium (Li). This level corresponds to commercial liquid electrolytes with ionic conductivities around 10 mS/cm and surpasses the previously developed highest ionic conductivity of argyrodite sulfide-based solid electrolytes at 14.8 mS/cm. The team applied the developed solid electrolyte to commercial cathodes and obtained initial capacities similar to those using liquid electrolytes, raising expectations for the development of high-energy, long-life lithium all-solid-state batteries through future optimization of battery manufacturing processes. The issue of hydrogen sulfide gas generation was also addressed by introducing antimony, which reduced reactivity with moisture and successfully decreased hydrogen sulfide gas generation by more than 70%.

Dr. Seungho Ryu stated, "The solid electrolyte developed in this study shows high ionic conductivity comparable to liquid electrolytes," adding, "It significantly improves the air stability of existing sulfide-based solid electrolytes and is expected to accelerate the commercialization of high-safety lithium all-solid-state batteries without explosion risks."

The research results were published in the latest issue of ‘ACS Energy Letters,’ an international journal in the field of energy materials (IF: 23.101, top 3.302% in JCR category).

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)