Hyundai Motor and Kia Face 1 Million Global Backorders Due to Semiconductor Shortage

Waiting Period for Popular Models Exceeds One Year

[Asia Economy Reporter Changhwan Lee] The backlog of orders for Hyundai Motor and Kia has reached an all-time high as the supply shortage of automotive semiconductors continues into the new year.

This is due to disruptions in the operation of global semiconductor component factories caused by the spread of the Omicron variant, resulting in insufficient parts supply that hampers vehicle production and significantly extends consumers' waiting periods.

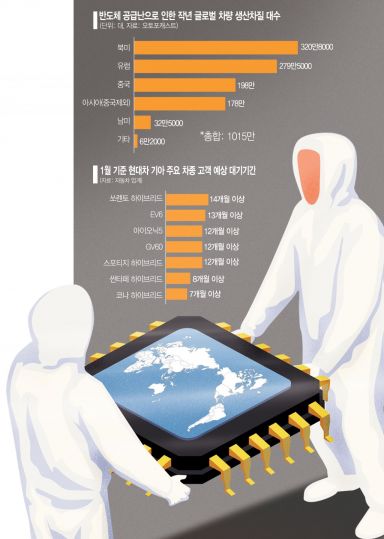

According to the automotive industry on the 18th, the backlog volume for Hyundai Motor and Kia this month has been confirmed to reach 1 million units each. Compared to the pre-COVID-19 period, this represents a twofold increase for Hyundai Motor and about a threefold increase for Kia, marking a record high.

The global shortage of automotive semiconductors, which began in earnest last year, remains unresolved this year, leading to a significant increase in backorders.

The automotive semiconductor supply shortage occurred because semiconductor demand surged after COVID-19, while production capacity remained limited.

The situation is similar in the global automotive industry. According to market research firm IHS Markit, as of the end of last year, vehicle inventory in the United States fell to below 1 million units, the lowest level ever recorded. Major automakers such as General Motors (GM), Ford, and Volkswagen are still experiencing shortages of automotive semiconductors.

With the rapid increase in electric vehicle sales, semiconductor demand is rising further, but the expansion of production capacity by automotive semiconductor companies is progressing slowly, leading to expectations that the supply shortage will continue this year.

According to the semiconductor industry, global automotive semiconductor companies have already received reservations exceeding about 20-30% above this year’s production capacity and are currently accepting orders for next year.

While orders are increasing, production has been disrupted due to COVID-19-related shutdowns of some semiconductor factories, causing lead times?the period from semiconductor order to delivery?to extend to more than 10 months, delaying the normalization of production.

As a result, consumer impact is growing. For popular electric vehicle models from Hyundai Motor Group such as the Ioniq 5, EV6, and GV60, even if a purchase decision is made now, receiving the vehicle within the year is impossible, requiring a waiting period of over 13 months. Popular hybrid sport utility vehicle (SUV) models like the Sorento and Sportage also have waiting periods exceeding one year.

Jominwook, a senior researcher at the Korea Automotive Research Institute, stated, "The automotive semiconductor supply shortage is expected to continue not only through the first half of this year but also into next year," adding, "However, the severity of the shortage is expected to gradually ease."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)