Korea Electrotechnology Research Institute

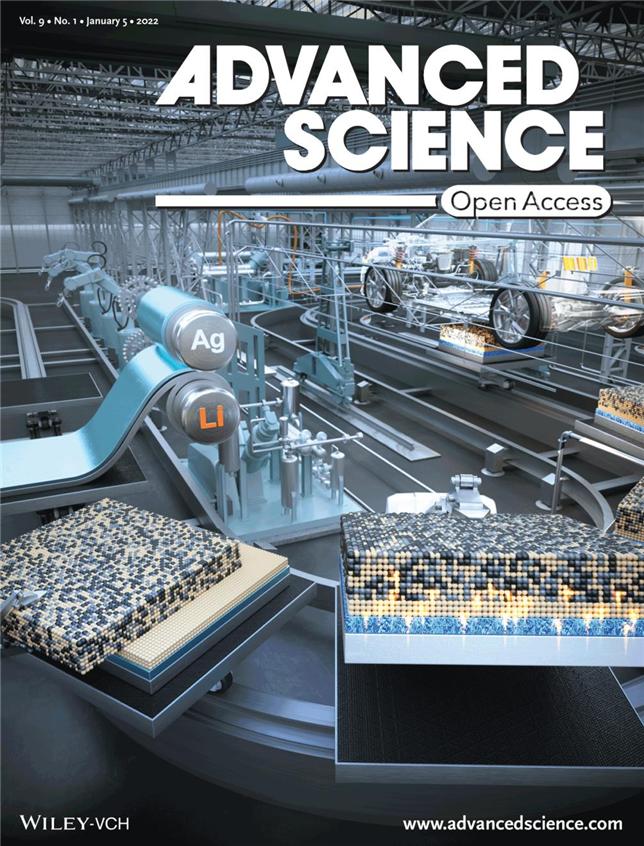

Research results on anode manufacturing technology for all-solid-state batteries by the Korea Electrotechnology Research Institute, published as the cover paper in the January issue of Advanced Science.

Research results on anode manufacturing technology for all-solid-state batteries by the Korea Electrotechnology Research Institute, published as the cover paper in the January issue of Advanced Science.

[Asia Economy Reporter Kim Bong-su] Domestic researchers have developed a next-generation all-solid-state battery with relatively stable performance by adding silver.

The Korea Electrotechnology Research Institute (KERI) announced on the 17th that its all-solid-state battery R&D team (researchers Ha Yoon-cheol, Kim Byung-gon, and Choi Hong-jun) developed a "sulfide-based all-solid-state battery anode manufacturing technology" that mixes silver into the lithium metal (Li-metal) anode material of next-generation all-solid-state batteries to achieve stable performance.

All-solid-state batteries replace the flammable liquid electrolyte used in conventional lithium-ion batteries with a solid electrolyte that has a lower risk of fire or explosion. Generally, lithium metal (Li-metal) is used as the anode material in all-solid-state batteries. The problem is that repeated charging and discharging causes lithium to grow in a tree-branch-like form on the lithium surface, known as 'dendrite growth,' which leads to internal short circuits and significantly reduces the battery's lifespan and stability. This has been one of the biggest technical challenges preventing the commercialization of all-solid-state batteries.

Various attempts have been made to solve this issue, such as chemically treating the lithium metal surface, introducing lithium storage structures, or replacing lithium with other materials. However, these methods showed limitations from a commercialization perspective due to complex manufacturing processes or reduced voltage.

The research team solved the problem by using silver (Ag), a lithium-affinitive material. They discovered that combining lithium and silver forms an alloy that thermodynamically creates a stable intermetallic compound phase. This acts as a physical protective layer that not only prevents dendrite growth but also improves chemical stability with sulfide-based solid electrolytes.

The team physically bonded lithium foil and silver foil using a 'roll-pressing' method suitable for large-area production. Through various electrochemical evaluations, X-ray Photoelectron Spectroscopy (XPS) analysis, and X-ray tomography, they confirmed that an all-solid-state cell applying the silver-lithium alloy anode could achieve a charge-discharge cycle life exceeding 140 cycles. Considering that currently commercialized lithium-ion batteries typically require over 300 cycles, KERI's technology represents a significant step toward solving the commercialization challenges of all-solid-state batteries.

The research results were published as a cover paper in the January issue of the international journal Advanced Science (IF 16.806), ranked in the top 5.3% of the Journal Citation Reports (JCR) materials science category.

The research team plans to build on this study by optimizing the amount of silver, a lithium-affinitive material, or exploring alternative materials to improve cost competitiveness. They also aim to develop prototype cells that can operate stably on a large scale.

Dr. Kim Byung-gon of KERI explained, "The anode greatly affects the battery's performance and lifespan, so designing it to reversibly store a large amount of lithium is key. Our technology preserves the high cell voltage advantage of lithium, suppresses the disadvantage of dendrite growth, and significantly enhances usability by manufacturing the anode on a large scale, marking a groundbreaking achievement."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)