Transparent Disclosure of Environmental Impacts Including Carbon Emissions

Simultaneous Low-Carbon Certification for Anode and Cathode Materials

Proactive Response to Strengthened Environmental Management Such as Mandatory EU Carbon Footprint

[Asia Economy Reporter Hwang Yoon-joo] POSCO Chemical has been recognized for its eco-friendly management achievements for the first time in the battery industry during the anode material production process.

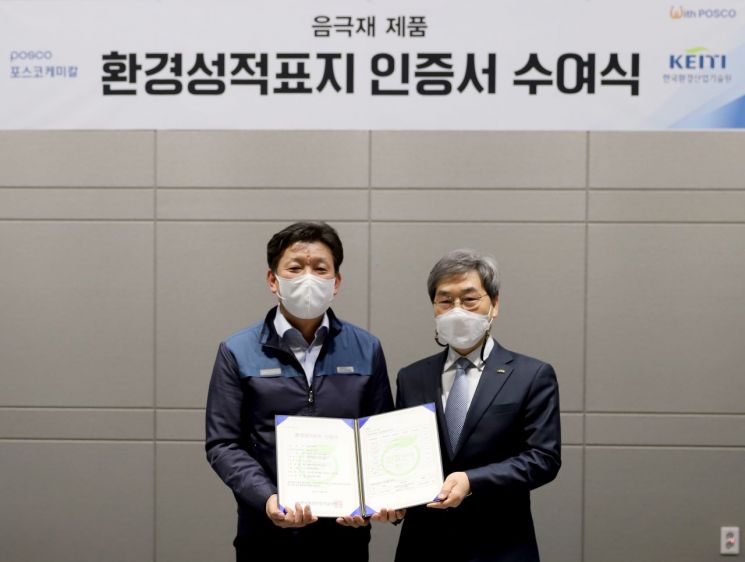

POSCO Chemical announced on the 6th that it has obtained the ‘Environmental Product Declaration’ certification from the Ministry of Environment for natural graphite anode materials, a core battery material.

The Environmental Product Declaration certification is a nationally accredited certification system that quantitatively displays and discloses the environmental impact throughout the entire process of a product, from raw material mining to production, use, and disposal. It is also used as an indicator for customers to choose environmentally friendly products.

POSCO Chemical disclosed seven major environmental impacts from raw material mining to the manufacturing process of anode materials, including carbon footprint, resource impact, water usage, ozone layer impact, acidification, eutrophication, and photochemical smog. The carbon footprint generated when producing 1kg of anode material is 3.24kg CO₂, which is approximately 175kg CO₂ when converted based on one 60KWh electric vehicle.

With this certification, POSCO Chemical has proactively responded to strengthening global environmental regulations and the enhanced environmental management of electric vehicle and battery customers by transparently disclosing the environmental impact of battery materials, thereby creating an opportunity to increase the eco-friendliness of the electric vehicle industry.

Electric vehicles are eco-friendly mobility with zero greenhouse gas emissions during driving, but it has been difficult to prove the overall product lifecycle eco-friendliness, including carbon emissions during the production process. Accordingly, environmental regulations in related industries are being strengthened, such as the European Union mandating battery carbon footprint reporting from 2024.

POSCO Chemical has made various efforts to produce eco-friendly materials, including increasing the use of renewable energy and obtaining the Circular Resource Quality Mark certification last September for recycling graphite dust generated in the anode material process as a resource. Additionally, it plans to obtain Environmental Product Declaration certification for cathode materials in the first half of next year and to reduce carbon emissions in the production processes of both cathode and anode materials to pursue low-carbon product certification.

Meanwhile, POSCO Chemical is actively pursuing technology development to secure differentiated product competitiveness. It supplies its independently developed low-expansion anode materials in line with the production timing of GM-LG Energy Solution’s battery joint venture ‘Ultium Cells’ and is concentrating research capabilities to develop new technologies that will lead the battery market, such as silicon anode materials that significantly increase electric vehicle driving range through enhanced energy density.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![User Who Sold Erroneously Deposited Bitcoins to Repay Debt and Fund Entertainment... What Did the Supreme Court Decide in 2021? [Legal Issue Check]](https://cwcontent.asiae.co.kr/asiaresize/183/2026020910431234020_1770601391.png)