-DGIST Dr. Kim Jungmin's Team Develops Hydrogen Sensor Using Palladium Nanogap

-Reevaluating Low-Concentration Hydrogen High-Resolution Detection Technology Essential for Preventing Gas Leak Accidents in Hydrogen Energy Use

[Asia Economy Reporter Kim Bong-su] Hydrogen gas, which is attracting attention as a next-generation energy source, is difficult to site for refueling stations due to its high explosiveness. However, a domestic research team has developed a detection sensor technology that can immediately detect hydrogen gas leakage and analyze its concentration, drawing interest.

The Daegu Gyeongbuk Institute of Science and Technology (DGIST) announced on the 4th that Dr. Kim Jeong-min's Nano Convergence Research Division team and Professor Lee Woo-young's Yonsei University team developed a palladium metal nano-gap based low-concentration hydrogen high-resolution detection technology. Unlike existing palladium metal-based hydrogen sensors, this hydrogen gas detection technology not only detects hydrogen the moment it is exposed but also enables quantitative analysis of the leaked hydrogen gas concentration.

Recently, as interest in hydrogen energy has increased, concerns about hydrogen gas, which has highly flammable and explosive properties, have also grown. Accordingly, the development of sensors that can quickly detect leaking hydrogen gas has also received much attention.

However, existing sensors detect hydrogen leakage through subtle changes in conductivity, which has limited accurate measurement of hydrogen leakage concentration. Palladium metal-based sensors that detect hydrogen gas work by detecting conductivity differences caused when palladium oxide particles meet hydrogen and are reduced to palladium particles.

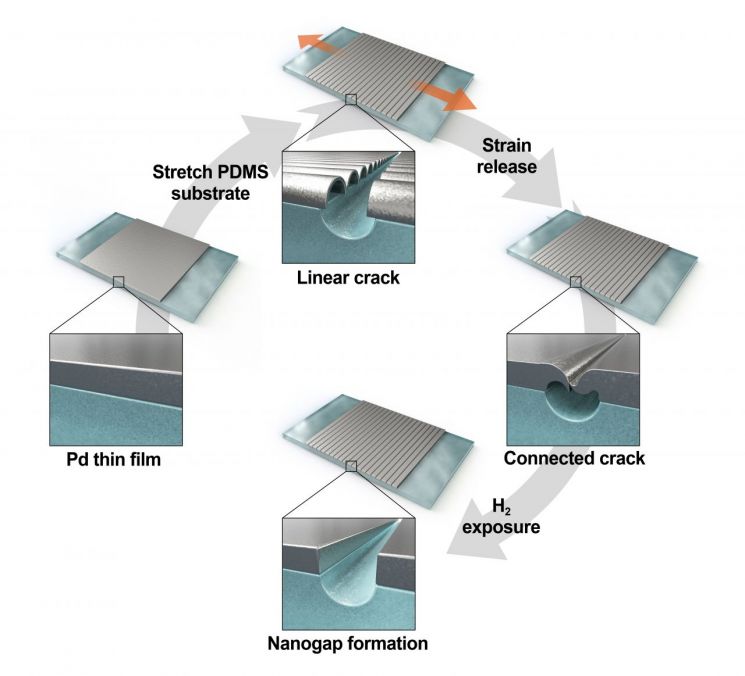

The research team developed a palladium metal nano-gap based low-concentration hydrogen high-resolution detection technology. It operates on the principle that the nano-gap is closed by the expansion of palladium metal due to leaked hydrogen gas, allowing electricity to flow and detecting the leakage. In particular, by utilizing the characteristic that the current flowing increases proportionally to the concentration of the leaking hydrogen gas, quantitative analysis of the leaking hydrogen gas can be performed.

Unlike existing sensors with high manufacturing costs, this sensor is made by coating palladium metal on a low-cost and flexible substrate (PDMS), enabling much cheaper production through an easier process.

The research results were published online on November 22 last year and selected as a frontispiece paper in the international journal of new materials science, Advanced Materials.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.