Professor Choi Nam-soon’s Team at KAIST Department of Bio and Chemical Engineering

[Asia Economy Reporter Kim Bong-su] Lithium metal batteries, which are attracting attention as next-generation battery technology, have a storage capacity much larger than lithium-ion batteries, making them suitable for electric vehicles and the like. However, commercialization has been difficult due to limitations such as short lifespan and instability. Recently, a domestic research team has developed an electrolyte additive that can significantly extend the lifespan of lithium metal batteries, paving the way for rapid commercialization.

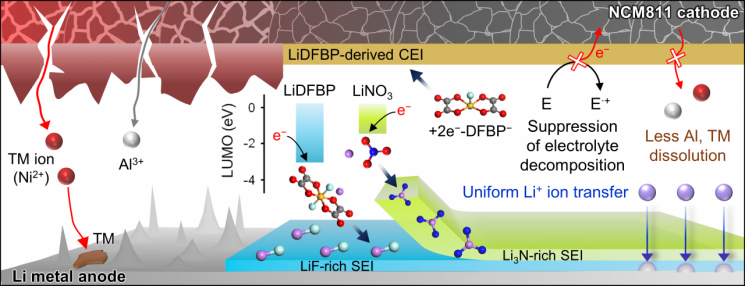

The Korea Advanced Institute of Science and Technology (KAIST) announced on the 16th that Professor Namsoon Choi’s research team in the Department of Biological Sciences and Chemical Engineering has developed an electrolyte additive technology that enables long lifespan for lithium metal batteries. The developed additive combination technology forms a desirable double-layer solid electrolyte interphase film on the lithium metal anode surface, suppressing lithium dendrite formation and uniformly delivering lithium ions, greatly improving the lifespan and fast charge-discharge characteristics of lithium metal batteries.

To realize long-lasting electric vehicles, it is necessary to increase the energy density, a core performance of batteries. Lithium metal batteries adopt lithium metal anodes that exhibit more than ten times the capacity of graphite used in lithium-ion batteries, achieving high energy density. However, if the reaction between the highly reductive lithium metal anode and the electrolyte is not properly controlled, achieving a long lifespan for lithium metal batteries is difficult.

The research team succeeded in dramatically extending the lifespan by introducing two types of ionic additives with different reduction reactivities and adsorption strengths, which allow the solid electrolyte interphase film to be layered and specify the functions of the formed double-layer interphase film. They also formed a thin interphase film protecting the nickel-rich cathode surface, securing structural stability of the cathode.

To solve the instability of the lithium metal anode, the team designed the formation of a double-layer solid electrolyte interphase film through sequential reductive decomposition of ionic additives based on electron-accepting ability and adsorption tendencies. The interphase film close to the lithium metal anode contains lithium fluoride (LiF) components with mechanical strength capable of withstanding stress from lithium plating-stripping reactions.

The outer interphase film includes lithium nitride (Li3N), which has excellent ion transport ability to uniformly supply lithium ions from the electrolyte. This hierarchical structuring technology of the lithium metal anode surface solid electrolyte interphase film can also be integrated with lithium-alloy-based anode materials, lithium storage structures, and anode-free technologies. It is expected to become a core electrolyte material technology realizing lithium metal batteries at levels demanded by industry. In particular, for anode-free secondary battery technology, which is expected to be a game changer that will reshape the secondary battery market, lithium metal forms on the anode substrate during charging, so electrolyte additive technology that stabilizes lithium metal will contribute to further enhancing the performance of anode-free secondary batteries.

The developed double-layer interphase film technology for protecting the lithium metal anode exhibited 80.9% of the initial capacity even after 600 charge-discharge cycles in batteries composed of lithium metal anodes and nickel-rich cathodes, showing a very high Coulombic efficiency of 99.94%.

Sehun Kim, a doctoral student in the Department of Biological Sciences and Chemical Engineering at KAIST, said, "By introducing lithium difluoro oxalate phosphate (LiDFBP) and lithium nitrate (LiNO3) as fluorine donor and nitrogen donor additives, respectively, the reversibility and morphology uniformity of the lithium metal anode were achieved. This double-layer interphase film minimized cross-talk with the cathode, preventing electrolyte decomposition at high voltages above 4V." He added, "We have developed electrolyte materials for high-voltage, long-life lithium metal batteries that surpass the limitations of previously reported electrolyte compositions for lithium metal batteries."

The research results were published online on the 25th of last month in the international journal Energy Storage Materials.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.