Development of Technology to Prevent Temporary Structure Safety Accidents Using Cloud-Based System Completed

Real-Time Measurement Enables Early Detection and Rapid Response to Ground Collapse, Groundwater Leakage, and Ground Subsidence

Pilot Site Trial Operation of the System Followed by Expansion to All Sites

Construction Company's First Safety Management Platform Equipped with Automated Measurement System to Prevent Safety Accidents

[Asia Economy Reporter Jo Gang-wook] Hyundai Engineering & Construction announced on the 9th that it has developed an automated measurement monitoring system that can integrate and manage the status of temporary structures and ground conditions on-site in real time to prevent collapse accidents that may occur during construction, and will apply it to the field.

Safety accidents involving temporary structures account for about 40% of all safety accidents in construction work, and when accidents occur, they can lead to damage to surrounding roads and buildings as well as casualties, making countermeasures urgently needed. Currently, information related to structural stability is measured manually twice a week, and separate data analysis is required to determine abnormalities. Therefore, it has been difficult to predict and respond immediately when warning signs occur.

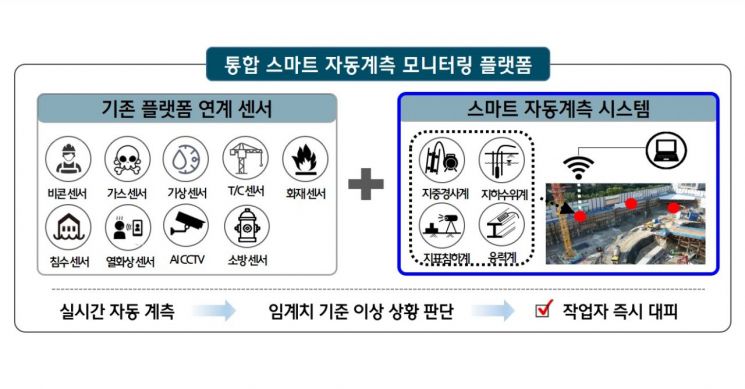

To fundamentally solve this problem, Hyundai Engineering & Construction developed a smart automated measurement monitoring system. This system monitors the safety of temporary structures in real time through automated measurement sensors installed on-site and a cloud-based system, thoroughly preventing safety accidents.

In particular, by linking with HIoS (Hyundai IoT Safety System), the on-site safety management system operated by Hyundai Engineering & Construction, data from the site is transmitted in real time, and automatic data organization and analysis are possible, allowing safety status to be understood anytime and anywhere. Through this, sites that were managed through separate measurements can be integrated and managed in real time, and signs of ground subsidence, ground collapse, and groundwater leakage can be detected in advance for immediate response.

Hyundai Engineering & Construction selected Hillstate Songdo The Sky as a pilot site to verify the technology’s reliability and usability, and plans to install the system on the safety management platform and expand its application to all sites starting in 2022.

A Hyundai Engineering & Construction official said, "The integrated smart automated measurement monitoring system is expected to make a revolutionary contribution to preventing safety accidents involving temporary structures and excavation accidents, which are the most frequent types of safety accidents," adding, "We will continuously strive to reduce not only collapse accidents during construction but all safety accidents on site through the continuous discovery and application of smart safety technologies."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.