Korea Institute of Machinery and Materials Develops 8-Color Glass with Self-Cleaning Function

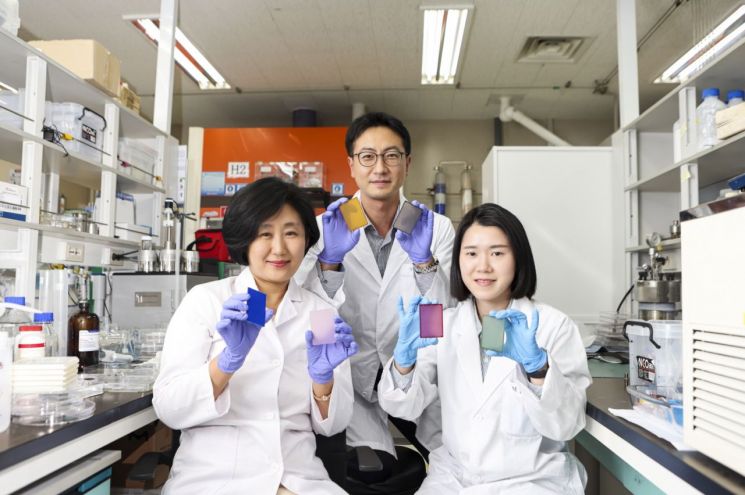

Im Hyun-ui, Head of the Nano Convergence Equipment Research Department at the Korea Institute of Machinery and Materials (left), Park Seung-cheol, Principal Researcher (center), and Yeo Seon-ju, Senior Researcher (right), are holding color glass with a self-cleaning function. Photo by Korea Institute of Machinery and Materials.

Im Hyun-ui, Head of the Nano Convergence Equipment Research Department at the Korea Institute of Machinery and Materials (left), Park Seung-cheol, Principal Researcher (center), and Yeo Seon-ju, Senior Researcher (right), are holding color glass with a self-cleaning function. Photo by Korea Institute of Machinery and Materials.

[Asia Economy Reporter Kim Bong-su] A special glass that can eliminate the so-called 'bird droppings glare' phenomenon caused by contamination of solar cells from bird droppings or dust has been developed.

The Korea Institute of Machinery and Materials announced on the 4th that it has developed a technology to produce high value-added colored glass that has beautiful colors and is resistant to contamination. It is expected to accelerate the commercialization of Building-integrated Photovoltaics (BIPV).

The research team, including Lim Hyun-ui, head of the Nano Convergence Equipment Research Division at the institute, senior researchers Park Seung-chul and Yeo Seon-ju, succeeded in creating glass with various colors and self-cleaning functions by coating the glass surface with high-performance nanomaterials such as metal and silica nanoparticles. Using the plasmonic effect of metal nanoparticles, they produced eight different colors of colored glass, including red, blue, and yellow, which are more durable than conventional colored glass. The transmittance can also be adjusted depending on the concentration of nanoparticles and coating thickness. Additionally, the glass surface was coated with eco-friendly water-repellent silica particles in a nanostructure to provide a self-cleaning function that repels contaminants.

The team installed a 3 kW solar cell module made with the self-cleaning colored glass on a building exterior wall and conducted a one-year test evaluation. The operation results confirmed stable efficiency reaching about 80% of the energy efficiency of existing solar modules. This not only approaches the efficiency of currently commercialized solar cells but also secures durability based on aesthetics and self-cleaning power. They developed not only the core technology for synthesizing nanoparticles but also equipment capable of uniformly coating 1㎡ scale surfaces. This equipment for uniform large-area nanoparticle coating can be applied not only to glass but also to films.

Currently, solar power panels are mainly made with dark blue glass. Although some modules are produced in color, they either use dyes that reduce stability or rely on metal deposition methods monopolized by specific companies, limiting their use.

The high value-added colored glass manufacturing technology developed by the research team secures core technology related to the synthesis of water-repellent silica nanoparticles and can be applied in various fields such as colored glass manufacturing, self-cleaning colored films, and superhydrophobic paint production.

Lim Hyun-ui said, “The idea for water-repellent silica nanoparticles came from the stone plate used to grill samgyeopsal, and the colored glass was inspired by stained glass in cathedrals,” adding, “I hope that solar cells using eco-friendly nanotechnology will be applied to architectural glass and exterior materials to help make our lives more sustainable.”

Meanwhile, recently, solar cells installed in areas such as Saemangeum in Jeonbuk have faced issues such as reduced power generation capacity and lifespan due to contamination by bird droppings and dust, sparking controversy over the so-called 'bird droppings glare.'

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)