Dr. Kim Jeongpil's Research Team at Korea Institute of Industrial Technology

[Asia Economy Reporter Kim Bong-su] A Korean research team has developed a technology that can detect even the tiniest defects in advanced carbon materials such as graphene by irradiating them with light, similar to X-ray nondestructive testing.

On the 28th, the Korea Institute of Industrial Technology announced that it has confirmed for the first time in the world that the ultra-fine defects of carbon materials can be detected through spectroscopic analysis using the wavelength of light, modeled on the nano structure of ‘Graphene,’ a dream new material well known worldwide.

The graphene structure is a planar structure 0.2 nanometers (nm) thick, where carbon atoms are connected in a hexagonal honeycomb pattern, serving as a fundamental model for various carbon material analysis studies. It is expected to be used as basic data for defect analysis in several material fields in the future, including ▲ultra-lightweight and high-strength carbon fiber reinforced plastics (CFRP), ▲graphite and activated carbon-based energy storage materials, and ▲next-generation electronic materials based on nanocarbon.

Ultra-fine defects at the nano scale inside carbon materials break the stable hexagonal honeycomb structure, altering the material’s inherent electrical and chemical properties. In such cases, optimizing the properties for the intended use becomes difficult, making accurate defect analysis crucial for expanding industrial applications and achieving material self-reliance.

Until now, nano-defect analysis has mainly relied on ‘morphological analysis’ using microscopes, which can only observe some surface structures accessible to the microscope, making it difficult to observe the entire internal structure and requiring a long observation time. Dr. Kim Jeong-pil’s research team at the Carbon Lightweight Materials Application Research Group of the Korea Institute of Industrial Technology started research on whether internal defects of carbon materials can be quickly identified and analyzed using a spectrometer that measures the wavelength of light, achieving results within a year.

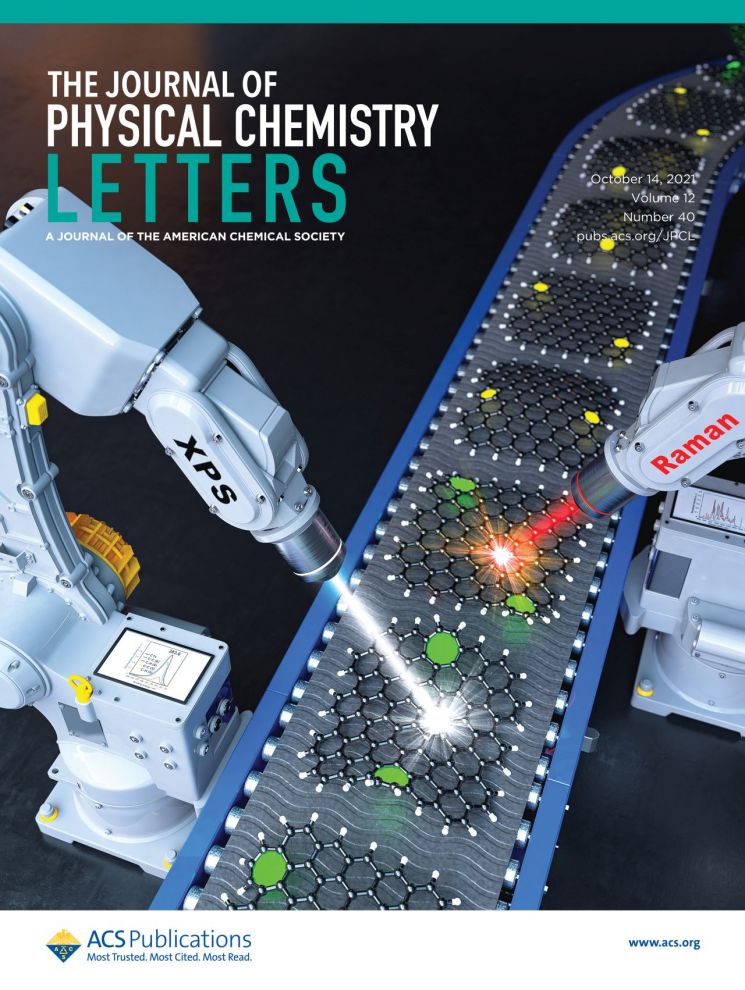

The research team first demonstrated, using computer simulation-based quantum chemical calculations, that spectral analysis of the surface chemical state and internal structure of carbon materials is possible with X-ray photoelectron spectroscopy and Raman spectroscopy, respectively, and clarified the theoretical principles. This is similar to the method of detecting invisible defects inside parts through X-ray nondestructive testing. Through spectroscopic analysis simulations, spectra of specific defect structures such as pentagons and heptagons, known in advance, can be derived, and their characteristics can be systematically accumulated and databased.

When combined with machine learning technology, even unknown carbon materials containing multiple complex defects can be analyzed by comparing with the accumulated defect structure database, allowing reverse inference of what defects are hidden, greatly improving the accuracy and speed of structural analysis.

Dr. Kim Jeong-pil said, “This research has secured fundamental technology and a database that can serve as a beacon to reveal the complex nano-defect structures of carbon materials,” adding, “It is expected to help develop next-generation carbon materials that can secure a comparative advantage over advanced countries in carbon materials such as Japan and the United States, and we plan to first apply it to ongoing biomass conversion carbon material R&D.”

The research results were selected as the front cover paper of the international academic journal ‘The Journal of Physical Chemistry Letters.’

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.