KRICT Develops Natural Material to Replace Petrochemical Materials Used in Bio-Plastic Production

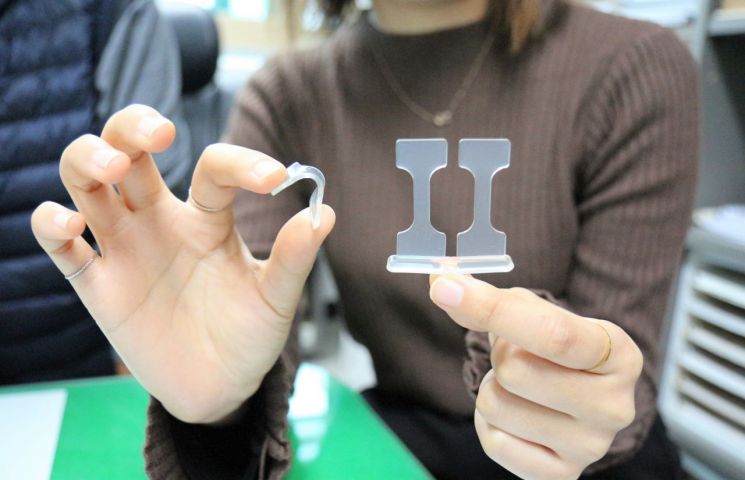

Biodegradable plasticizer lactide oligomer capable of producing 100% biodegradable bioplastics. Photo by Korea Research Institute of Chemical Technology

Biodegradable plasticizer lactide oligomer capable of producing 100% biodegradable bioplastics. Photo by Korea Research Institute of Chemical Technology

[Asia Economy Reporter Kim Bong-su] Domestic researchers have developed a natural material that can replace petrochemical fuels used in the production of eco-friendly biodegradable bioplastics. This breakthrough enables the production of 100% fully degradable bioplastics and minimizes carbon emissions during the manufacturing process, potentially accelerating future commercialization.

On the 27th, Dr. Shin Ji-hoon’s research team at the Korea Research Institute of Chemical Technology’s Environmental Resources Research Center announced their success in developing a sustainable raw material-based biodegradable plasticizer that can complement the brittle shortcomings of polylactide (PLA), a biodegradable plastic polymer gaining attention as an eco-friendly material.

Among biodegradable plastics, which serve as alternatives to non-degradable conventional single-use plastics, PLA is the most widely produced and industrialized material. PLA is a harmless, eco-friendly material that can be completely decomposed under certain conditions after use. The PLA market is expected to grow annually by 20-30%, reaching approximately 7 trillion KRW and over 1.5 million tons by 2025.

The problem is that petrochemical-based plasticizers are used to compensate for PLA’s hardness and brittleness during processing. These plasticizers do not decompose, ultimately resulting in carbon emissions. Therefore, there has been an urgent need to develop biodegradable plasticizer manufacturing technology that provides PLA with suitable flexibility while being biodegradable.

The research team synthesized lactide oligomers, which can mix well with PLA, using lactide?the monomer commonly used in PLA polymerization?through a solvent-free eco-friendly manufacturing process. This marks the development of the first biodegradable PLA plasticizer. The lactide oligomers created by the team have a structure similar to PLA chains, resulting in excellent compatibility and nearly identical transparency to PLA. Notably, about 78% natural degradation was confirmed after 28 days.

Using this plasticizer, the elongation rate (stretchability) was increased up to seven times compared to the existing level, securing PLA’s flexibility. They also discovered a very unusual phenomenon where the plastic exhibited viscoelasticity?stretching and contracting like rubber?in a highly flexible state.

The PLA developed by the research team is expected to be applied in general-purpose film packaging materials requiring biodegradability, such as volume-based waste bags, due to its excellent flexibility, high biodegradability, transparency, and rubber-like viscoelastic properties. This achievement is also considered highly significant in the domestic research environment, where fundamental research on polymer additive development is limited.

Im Mi-hye, President of the Korea Research Institute of Chemical Technology, stated, “Through this achievement, we have secured core technologies for manufacturing and flexibilizing eco-friendly biodegradable PLA plasticizers necessary for achieving a carbon-neutral society. We also look forward to commercialization and product development in collaboration with companies interested in PLA commercialization.”

The research results were published as the cover paper in the October issue of Green Chemistry (IF: 10.182), an international journal in the field of clean chemistry published by the Royal Society of Chemistry, one of the world’s top three chemical societies.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)