First Step in Servo Motor Development by Japanese Company... Localization of Core Actuator Components

Service Robot Development Since 2009... Industry's First Delivery Robot Demonstration

Indoor Delivery Robot to Be Deployed in Hotels in August... "About 2 Years Until Commercialization"

[Asia Economy Reporter Lee Junhyung] An actuator is a modular component composed of a motor, reducer, controller, etc., serving as the joint of a robot. It is an essential core part required for robot operation and demands high technical expertise, resulting in a high unit cost. The reducer alone accounts for 30-40% of the robot production cost. According to the market research firm MarketsandMarkets, the global robot actuator market size is expected to reach 36 trillion KRW by 2024.

Robotis has been developing robot actuators since 2003. Robotis's actuator "Dynamixel" was recognized for its solid technology to the extent that it was re-exported to Japan shortly after development. The supply price was about 20% lower than overseas products, giving it price competitiveness. Large companies such as LG Electronics also use Robotis's actuators. In 2019, it was selected as a world-class product by the Ministry of Trade, Industry and Energy and KOTRA.

Servo Motor Development as a Trigger... Internalization of Reducers

Robotis started as an educational robot manufacturer in 1999. In the early 2000s, while growing its business through smart toys applying robot technology, a Japanese robot company requested the development of a servo motor optimized for its products. Unlike general motors that move in only one direction, a servo motor can precisely control position, speed, etc. The company devoted two years to developing the servo motor and successfully delivered it to the client. This became a turning point for the company to leap forward as a robot parts manufacturer. Robotis CEO Kim Byungsoo explained, "At that time, we had basic technical capabilities and the company was small, so we could respond quickly. We have continuously developed actuators since exporting to Japan."

The company internalized core actuator components one by one. Without securing the core technologies of actuators such as motors and reducers, it was difficult to improve not only price competitiveness but also profitability. The reducer is one of the components with overwhelmingly high dependence on Japan. After repeated research and development (R&D), the company began mass production of its self-developed reducer "DYD" from the first half of this year. The unit price was reduced to about 80% of existing products. According to the company's experiments, DYD's shock resistance was nearly three times higher than that of products from the Japanese Harmonic Drive company. The company explained that by reducing size and weight, it can be used broadly in collaborative robots and other service robots.

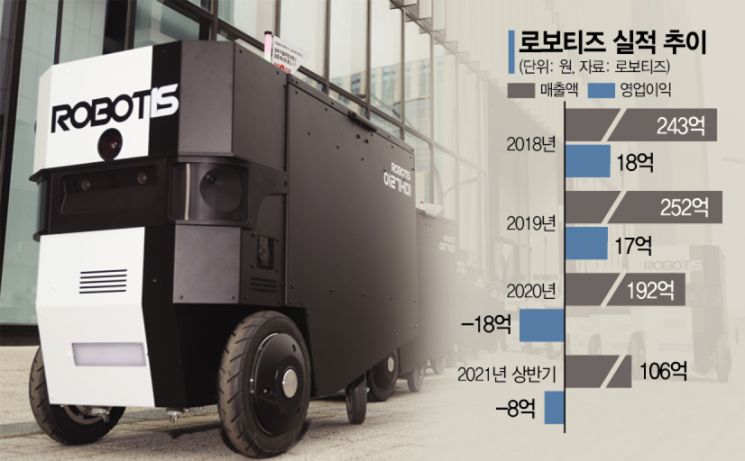

Indoor delivery robot by Robotis. It was deployed in August this year at a hotel located in Jung-gu, Seoul.

Indoor delivery robot by Robotis. It was deployed in August this year at a hotel located in Jung-gu, Seoul. [Photo by Robotis]

Betting on Service Robots... Indoor Use Deployed in Hotels

Since 2009, the company has ventured into service robot development. CEO Kim predicted that the robot industry would shift from manufacturing-centered industrial robots to service robots. The emergence of home cleaning robots reinforced this conviction. Kim said, "With the commercialization of cleaning robots, the concept of service robots began to be recognized. When the medical surgical robot 'Da Vinci' was released, I realized that robots would no longer be confined to factories."

Currently, the company is focusing its R&D capabilities on delivery robots. It began developing AI-based autonomous delivery robots in 2018. Thanks to passing the regulatory sandbox at the end of 2019, it started the industry's first outdoor delivery robot demonstration last year. The company has been operating dozens of its self-developed delivery robots "Ilgaemi" on a trial basis near its headquarters located in the Magok district of Gangseo-gu, Seoul. CEO Kim said, "The know-how accumulated from developing the research-use autonomous driving robot 'TB3,' commercialized five years ago, has been helpful. Compared to other companies, our strength lies in technological competitiveness in robot hardware (HW) fields such as actuators."

The indoor delivery robot "Jipgaemi" has been providing services to actual customers at a hotel located in Jung-gu, Seoul, since August this year. Jipgaemi has a robotic arm on top of its body that can press elevator buttons and knock on doors. CEO Kim said, "It will probably take about two more years to commercialize to make costs realistic. However, delivery robots are expected to achieve autonomous driving before cars do."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

!["The Woman Who Threw Herself into the Water Clutching a Stolen Dior Bag"...A Grotesque Success Story That Shakes the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)