[Asia Economy Yang Nak-gyu, Military Specialist Reporter] The fuselage of the Korean fighter jet KF-21 Boramae (hereafter KF-21), unveiled last April, consists of 381 parts and over 9,500 hardware components. Even a single faulty part in processing or assembly can cause structural problems, so meticulous attention must be paid from the design stage. This is why Korea Aerospace Industries, which manufactured the KF-21, uses the 3D digital design program from the French defense company Dassault Syst?mes. To see the program, I visited Dassault Syst?mes headquarters located in Gangnam-gu, Seoul, on the 16th. Upon entering, about 30 large monitors were mounted on the wall. The monitors displayed 3D designs of warships, unmanned aerial vehicles, and fighter jets. Center Director Kim Hyun-jin said, "3D digital design allows us to predict all processes from conceptualizing weapon systems to design, test flights, and production processes," adding, "In the past, countless design drawings were manually created to build physical models for testing fighter jets, but now we can draw blueprints inside a computer, create virtual physical models, and even conduct test flights."

The first monitor displayed multiple graphs at a glance, showing performance results. It was a graph for managers to check the progress rate of each process at a glance. Clicking the production process folder showed the status of parts assembly and expected shipment dates. Traditional defense companies communicate by gathering thousands of engineers who exchange emails. However, in 3D digital design, opinions from each department are shared in real time, and proposals such as design changes are immediately applied to the blueprints.

European aerospace giant Airbus also utilized Dassault Syst?mes' 3D digital design when manufacturing the A350 aircraft using carbon fiber composite materials. Using carbon fiber reduces external noise by 50% and is aerodynamically efficient, but since it was the first attempt, significant time and costs were inevitable. Airbus chose 3D digital design. As a result of up to 4,000 engineers collaborating online daily, time and costs were reduced. The same applies to Israel's Eviation Aircraft. Eviation used 3D digital design from the start when building the 9-seater electric aircraft Alice. During production, a problem arose with the device that secures seats to the aircraft floor. Due to a shortage of securing devices, assembly could not proceed further. However, a French company found a substitute, and within just 30 seconds, the substitute was applied and the revised model was shared with all workers. A company official said, "Because this program allows numerous engineers scattered worldwide to coordinate opinions and collaborate simultaneously, defense companies targeting exports prefer 3D digital design."

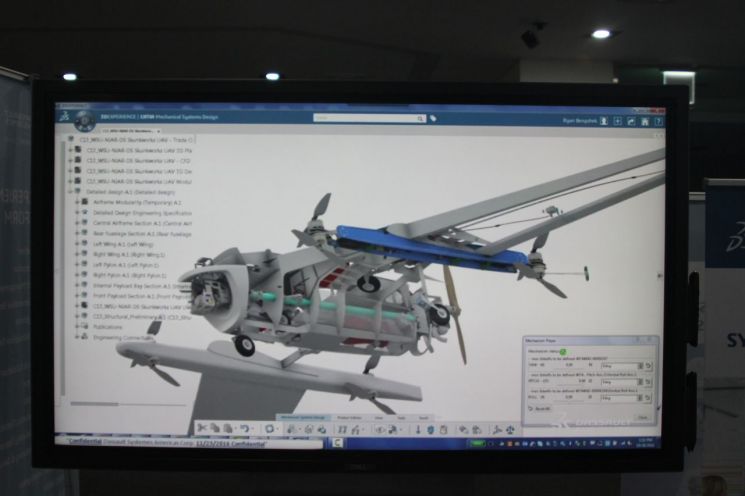

Looking at the adjacent monitor, a virtual unmanned aerial vehicle was flying on a 3D screen. In the past, after completing the design, a mock-up was made for testing. A mock-up is a physical model smaller than the actual size. The mock-up was fixed inside a test chamber to calculate the effects of wind strength and airflow. Using 3D digital design, a virtual digital mock-up can be created and tests applying environmental factors can be conducted. Costs are reduced by more than 50%. A company official said, "Dassault Syst?mes first conducted digital mock-up testing and evaluation with Boeing's 777 model in 1990," adding, "3D digital design can be applied not only in defense but also in automotive, energy, and life sciences fields." Dassault Syst?mes' 3D digital design is also used in wine production. Ch?teau Dassault Winery, established in 1955, predicts and manages vineyard drainage maintenance, defect minimization, and pest control.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![Clutching a Stolen Dior Bag, Saying "I Hate Being Poor but Real"... The Grotesque Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)