RS Automation Achieves 'Technological Independence' in Industrial Robots with Domestic Motion Controller

Led by Samsung Electronics Automation Team... Developed Ultra-Precision Encoder Sensors Following Japan and Germany

Also Introduced Conveyor Belt Replacement Solutions... Receiving Love Calls from Major Companies like LG

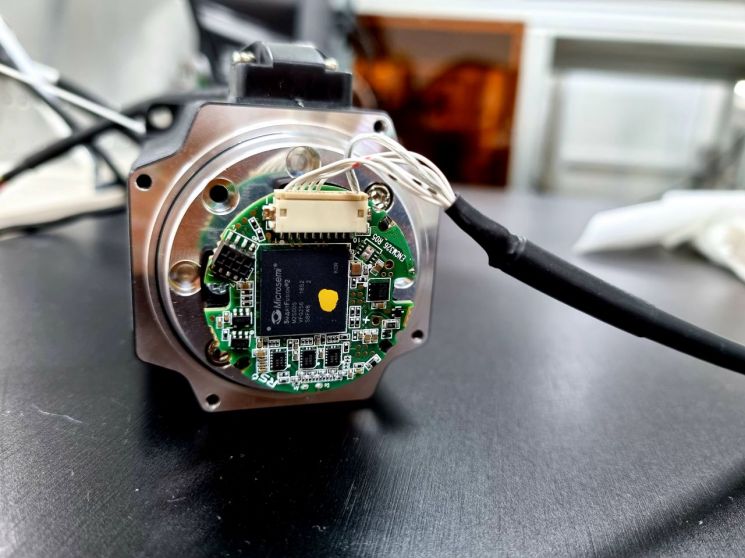

A 22-bit high-performance encoder developed by RS Automation following Japan and Germany.

A 22-bit high-performance encoder developed by RS Automation following Japan and Germany. [Photo by Joonhyung Lee]

[Pyeongtaek=Asia Economy Reporter Lee Junhyung] Industrial multi-joint robots are the "heart" of factory automation equipment. They are deployed in advanced processes such as semiconductors and displays to perform difficult or complex tasks accurately and repeatedly. With the Fourth Industrial Revolution, the manufacturing sectors applying industrial robots are expanding, and the market is steadily growing.

The problem lies in overseas dependence. Industrial robots have high technological entry barriers, leading to a strong reliance on manufacturing powerhouses for everything from key components to finished products. In fact, the Small and Medium Business Corporation analyzed in 2019 that the market share of five major companies from Japan, Germany, Switzerland, and others reached 87%.

RS Automation is leading technological independence in industrial robots. The company has localized the robot motion controller that controls the operation of industrial robots. This component precisely controls the robot's position and speed and acts as the central processing unit (CPU) of the industrial robot. It is considered a kind of "robot brain" and a core technology of industrial robots. The company directly develops related core technologies such as PLC (Programmable Logic Controller) and MMC (Multi Motion Controller) that make up the controller and provides integrated solutions.

Spun off from Samsung Electronics... Competing with Japan and Germany

The technology was not completed overnight. Although the company is now in its 11th year since establishment, actual technology development has been steadily progressing since 1995. At that time, Samsung Electronics established an automation team aiming to internalize the robot motion controller. However, due to the aftermath of the 1998 financial crisis, Samsung Electronics withdrew from this business, and the team spun off to start a new company. Later, in 2002, the company was absorbed into the Korean subsidiary established jointly by Rockwell Automation, the No.1 industrial robot company in the U.S., and Samsung Electronics. This subsidiary became the predecessor of the company. Lee Kang, Vice President of RS Automation, explained, "Core personnel who researched automation equipment at Samsung Electronics in the past became the main force of the company," adding, "Our technological capabilities are the result of 26 years of dedicated research and development."

Encoders are one of the achievements that prove the company's technological prowess. An encoder is an ultra-precision sensor installed in the robot joints. It detects the motor's direction and rotation count and exchanges signals. It can precisely control a motor rotating 360 degrees to a unit of one eight-millionth. This requires advanced technology, and the product cost accounts for 30-50% of the motor's cost. In 2014, the company secured the core technology of 22-bit encoders, becoming the third in the world after Germany and Japan. The company's encoders have been recognized for reliability to the extent that motors equipped with them will be supplied to Samsung Electronics' Pyeongtaek 3 Campus, scheduled for completion in the first half of next year.

Exterior view of the RS Automation headquarters located in Pyeongtaek, Gyeonggi. [Photo by RS Automation]

Exterior view of the RS Automation headquarters located in Pyeongtaek, Gyeonggi. [Photo by RS Automation]

Core Components of Smart Factories... ‘Love Calls’ from LG and Others

The company is establishing itself as a vanguard in the smart factory industry. A smart factory is an intelligent production facility that enhances the entire production process from product design to manufacturing and distribution using information and communication technology (ICT). According to the company, demand for robot motion controllers is rapidly increasing as they are widely applied not only to industrial robots but also to collaborative robots on production lines. Thanks to the localization of core technologies, the company has price competitiveness and can provide immediate after-sales service (AS) upon customer requests by producing controllers with its own technology. The vice president said, "We already achieved the No.1 sales position in the domestic market in 2013," adding, "We are the only company exporting motion controllers from Korea."

Major corporations have also continued to show interest in the smart factory solutions developed by the company. The MMD (Moving Magnet Drive) solution applied at LG Display's factory is a representative example. It is a kind of "moving magnet" solution that replaces conveyor belts. Unlike conveyor belts, it produces no noise or dust, making it optimized for semiconductor and display processes conducted in vacuum and sterilized environments.

The company also solved the chronic problems of conveyor belts. In conveyor belt factories, processes proceed step by step, so if a problem occurs in one process, the entire operation must stop. In contrast, MMD divides all processes into cells, allowing each process to operate independently. The vice president stated, "After competing in performance with Germany's BOSCH, we supplied to LG Display," adding, "It will become a core technology for production logistics automation underway in advanced industries."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.