Professor Son Seok-su's Research Team Finds Clue to 'Medium-Entropy' Alloy That Catches Both Strength and Ductility

[Asia Economy Reporter Kim Bong-su] A technology has been developed to alloy an "ideal metal" that is ultra-high strength yet highly stretchable. Generally, metals tend to be brittle the harder they are. If a metal can possess both hardness and flexibility, it could bring disruptive innovation to various material markets.

The National Research Foundation of Korea announced on the 8th that a joint research team led by Professor Son Seok-su (Korea University) and Professor Choi Byeok-pa (KAIST) has found a clue to ultra-high-strength, high-ductility medium-entropy alloys that achieve the difficult combination of strength and ductility.

Typically, precipitation is used to synthesize high-strength alloys. When several metals are melted and evenly mixed, then cooled, alloying elements exist in a supersaturated state inside the metal. Applying heat to these supersaturated elements causes them to precipitate as particles, which hardens the metal.

The smaller and more evenly distributed the particles, the higher the alloy's strength. It was known that the size and distribution of particles are determined by the properties of the interface between the metal and the particles.

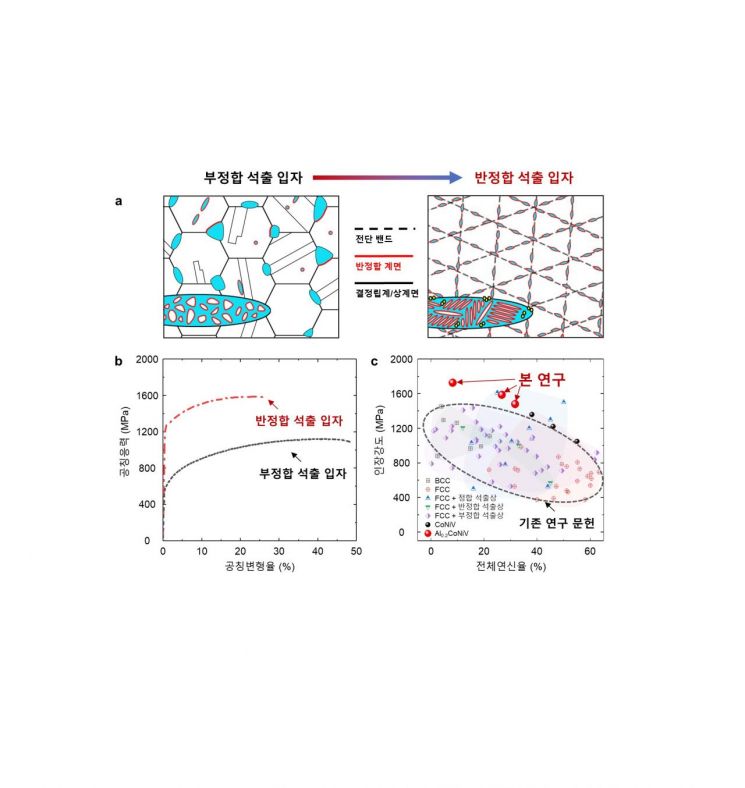

If the interface has unstable high energy, particles grow rapidly to relieve this energy. To prevent this, conventional methods used coherent interfaces that continuously connect the atomic arrangements of the metal and particles. This was to reduce the interface energy and suppress particle growth. However, since elements that form precipitates with coherent interfaces are very limited, it was difficult to utilize various precipitate particles in alloys.

The research team proposed the possibility of designing ultra-high-strength medium-entropy alloys by utilizing semi-coherent interface particles, departing from the conventional approach. By using semi-coherent interfaces that connect atomic arrangements of the metal and particles at specific intervals, they lowered the interface energy and delayed particle growth. When force was applied to the metal, precipitate particles of tens of nanometers in size were formed at regions where permanent deformation concentrated along specific directions. The deformation concentration zones were uniformly formed throughout the alloy, enabling even distribution of precipitate particles. As a result, they obtained a medium-entropy alloy with a tensile strength (1.6 GPa) comparable to ultra-high-strength steel sheets and high ductility (27%) that resists fracturing even when deformed. Following confirmation of mechanical properties at room temperature, the research team plans to conduct follow-up studies on mechanical properties under high-temperature and cryogenic conditions.

The research results were published on the 4th of last month in the international journal Nature Communications.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.