Research Team Led by Professor Lee Man-jong at Konkuk University Successfully Fabricates Perovskite Solar Cells Without 'Dry Room'

Lowering Process Costs and Simplifying Production Pave the Way for Rapid Commercialization

[Asia Economy Reporter Kim Bong-su] A fabrication method that can reduce the high capital investment costs, which have been an obstacle to the commercialization of next-generation high-efficiency solar cells, has been developed by Korean researchers.

The National Research Foundation of Korea announced on the 6th that the research team led by Professor Lee Man-jong of Konkuk University succeeded in fabricating perovskite solar cells in a humid environment comfortable for humans, rather than in a glove box isolated from outside air or a dry room with controlled humidity.

Perovskite solar cells use perovskite materials as the light-absorbing layer instead of silicon. Their highest efficiency is 25.5% (for mixed cation perovskite solar cells), which is comparable to silicon solar cells (26.7%), and they can be fabricated using a simple solution process. They also have the advantage of low efficiency variation depending on the angle of incident sunlight, enabling the production of curved and flexible solar cells. However, challenges such as large-area fabrication, long-term stability, and manufacturing equipment remain for commercialization. In particular, at high humidity, the precursor solution combines with moisture, hindering the formation of high-quality perovskite crystals, so dry rooms with low humidity had to be installed.

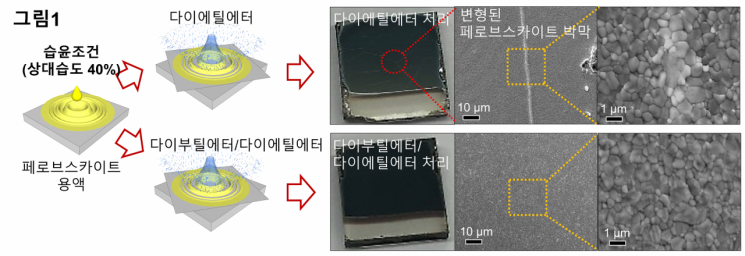

The research team overcame this by developing a new anti-solvent washing method that allows fabrication in a general humid atmosphere (relative humidity > 40%). To offset the effects of humidity, they developed a process to remove solvents using an anti-solvent mixture of dibutyl ether and diethyl ether, which have complementary properties of low vapor pressure and low boiling point. This was to overcome the rapid evaporation of chlorobenzene and diethyl ether, previously used for solvent removal, in humid environments, which caused deformation or stress in the perovskite photoactive layer. The perovskite solar cells produced in this way showed the highest efficiency (22.06%) and stability (maintaining 94% of initial efficiency after 1200 hours) among perovskite solar cells fabricated under humid atmospheric conditions. Furthermore, they identified that the reaction with moisture during the perovskite thin film fabrication process causes surface roughness on the thin film, and the charge transport degradation caused by this roughness leads to a decrease in solar cell efficiency.

Professor Lee said, "We demonstrated that high-efficiency perovskite solar cells can be realized even under humid environmental conditions, breaking away from the constraints of strictly controlled environments."

This result was published on July 30 in the international academic journal in the energy and materials field, Nano Energy.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.