Suspension of Local Factory Operations Due to Variant Virus Spread

Direct Hit to Samsung Factory in Ho Chi Minh, Vietnam Under Lockdown

Samsung TV Delivery Takes at Least 4 Weeks

Automobile Industry Also Faces Semiconductor Supply Shortage from Malaysia

[Asia Economy reporters Su-yeon Woo and Ki-min Lee] "Due to production disruptions at the Vietnam factory, customers have to wait more than a month for TV delivery. There are too many Southeast Asian local factories (including parts factories) that have halted operations due to the spread of variant viruses. Even if domestic orders come in, production volume is extremely limited, so we cannot guarantee when customers will receive their products at this time." (Samsung Electronics dealership official)

As the spread of COVID-19 variant viruses intensifies in Southeast Asia, domestic companies with production and parts factories in the region are facing a crisis in supply chain operations. The shortage of local products and parts is affecting domestic sales networks, causing the waiting time for domestic consumers to become indefinitely long.

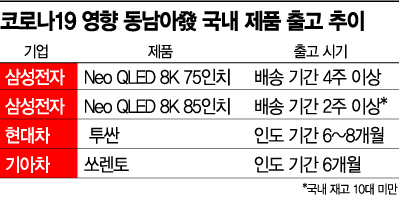

According to the industry on the 26th, recent domestic delivery of major Samsung Electronics TV products takes at least four weeks. The new Neo QLED 8K 75-inch TV requires a minimum of four weeks for delivery, and the domestic stock of the recommended Neo QLED 8K 85-inch model is understood to be fewer than 10 units.

The shortage of home appliances caused by the spread of COVID-19 in Southeast Asia shows no signs of easing. The operating rate of Samsung Electronics' Ho Chi Minh City factory in Vietnam, which had dropped to the 60% range earlier this month, recently fell to the 30% range. To make matters worse, on the 23rd, Ho Chi Minh City issued a full lockdown banning all outings, worsening the situation at local factories. If Samsung Electronics' Ho Chi Minh factory closes, the estimated daily loss is about 17.1 billion KRW.

A Samsung Electronics official said, "The domestic supply situation has deteriorated sharply due to production disruptions in Vietnam for a long time. We managed by depleting remaining domestic stock until August orders, but now even the stock is almost exhausted. Even if orders are placed now, the earliest delivery will likely be after Chuseok."

LG Electronics, which has a factory in Hai Phong in northern Vietnam far from Ho Chi Minh City, is relatively less affected. LG Electronics has home appliance and automotive parts production facilities in the Hai Phong industrial complex. For TVs, production from the Gumi factory is directly supplied domestically, so popular OLED TV models are reportedly deliverable within 2 to 3 days. However, the company is closely monitoring the situation as the COVID-19 impact in Vietnam could spread to the northern region.

The completed car industry, which has semiconductor parts factories concentrated in Southeast Asia, is also facing difficulties. Recently, Hyundai Motor reportedly suspended production of the '2.5 gasoline turbo' engine installed in the Grandeur and GV80 due to supply issues with engine control units (ECU) sourced from Malaysia. The shutdown of semiconductor production factories in Malaysia has worsened domestic finished car production and sales disruptions. An industry official said, "Hyundai plans to resume engine production from the 27th, but due to unstable semiconductor supply, production volume will be adjusted."

Hyundai Motor and Kia are facing shortages not only of ECUs but also other key parts such as transmission control units (TCU) for dual-clutch transmissions (DCT), front camera semiconductors, and airbag control units (ACU). The companies are making every effort to avoid the worst-case scenario of a shutdown by swapping semiconductor parts by model and adjusting production volumes of new cars like the new Sportage.

As a result, delivery periods for Hyundai and Kia's main models such as the Ioniq 5 (over 10 months), Tucson (6 to 8 months), and Sorento (6 months) have extended up to 10 months. Especially for electric vehicles, which require more semiconductors than internal combustion engine vehicles, the backlog is even more severe.

A Hyundai Motor salesperson said, "The global semiconductor shortage combined with the Malaysia shutdown issue is worsening the situation. Since supply is difficult at the production stage, the sales front is also frustrated." A Kia salesperson added, "We are struggling to secure vehicles rejected by customers, display cars, and vehicles with contract or option changes to meet demand, but even these are hard to obtain. Competition among salespeople to secure inventory is becoming fierce."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.