Utilization of Skin-Attached Wearable Device Components

Successful New Development Devised by 'Floating Alignment Method'

Combines Elasticity, Thickness, and High Conductivity

[Asia Economy Reporter Kim Bong-su] Korean researchers have developed the world's highest-performance nano-thin film electrode that can be used as a core component of skin-attachable wearable devices.

The Institute for Basic Science (IBS) announced on the 27th that the research team led by Deputy Director Kim Dae-hyung of the Nanoparticle Research Division and Director Hyun Taek-hwan published this paper in the international journal Science (IF 47.728).

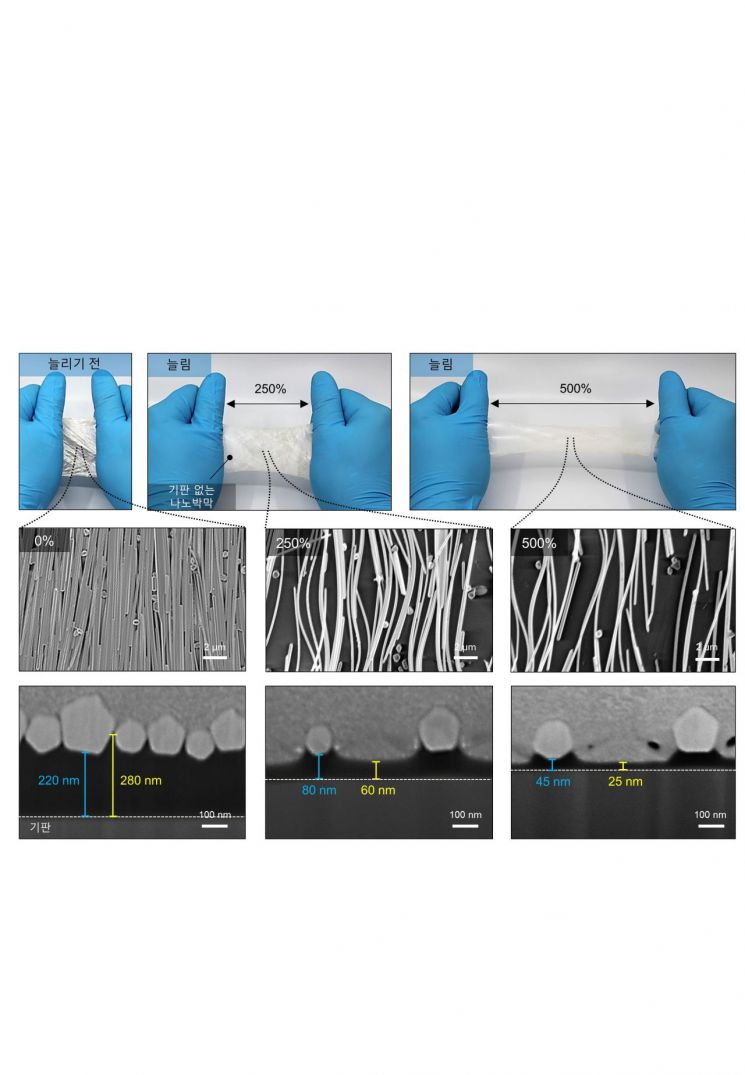

The research team manufactured a high-performance nano-thin film electrode possessing high conductivity, nano thickness, and excellent stretchability?all of which were impossible to achieve with existing methods?through a new development method called the ‘Float assembly method.’ It conducts electricity as well as metal but is as thin as one three-hundredth the thickness of a human hair (250 nm). It has high stretchability, making it applicable as a core component of skin-attachable wearable devices. Skin-attachable wearable devices must have mechanical properties similar to those of the skin. Therefore, the electrode, a core component of the device, must have excellent stretchability, high electrical conductivity, thin thickness, and also allow high-resolution patterning.

The ‘Float assembly method’ developed by the research team proceeds in three stages. First, a mixture of silver nanowires, rubber, ethanol, and other substances is dropped into a water tank; second, a surfactant is added; and third, the solvent is dried. When the mixture is dropped drop by drop onto the water surface, the silver nanowires are neatly aligned along the edges of the tank by the ‘Marangoni flow’ (fluid flow caused by local surface tension differences) spreading from the center outward. Then, when a small amount of surfactant is added to the center of the tank, the silver nanowires aligned at the edges are pressed closer together. Finally, as the solvent evaporates, a thin rubber film remains, and a nano-thin film electrode structure is formed in which a densely packed monolayer of silver nanowires is partially embedded in the nano-thin film. The manufacturing time is very short, about 5 minutes.

The electrical conductivity of the synthesized nano-thin film electrode is 100,000 S/cm, comparable to that of metal. Even when stretched up to 10 times its original length, its electrical properties are maintained without mechanical defects. The thickness is about 250 nm, making it very thin and able to adhere closely to curved surfaces like skin.

The research team also succeeded in high-resolution patterning with a line width of 20 μm using ultraviolet photolithography (engraving desired circuits on substrates using light-reactive polymers). This means that the nano-thin film electrode can be cut into desired shapes and made into various electronic devices. Using the nano-thin film electrode, they developed a skin-attachable multifunctional stacked device and demonstrated that various biosignals such as electromyography, humidity, temperature, and tensile force can be simultaneously monitored on the skin.

Deputy Director Kim Dae-hyung said, "High-performance stretchable nanoelectrodes will be widely used in next-generation wearable devices and will greatly contribute to the development of this field," adding, "Because the ‘Float assembly method’ can combine not only metallic conductive nanomaterials but also various types of nanomaterials such as semiconductors and magnetic materials with rubber, it will be developed into various high-functional stretchable nanomaterials."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

!["The Woman Who Threw Herself into the Water Clutching a Stolen Dior Bag"...A Grotesque Success Story That Shakes the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)