200 Times Stronger Than Steel, 100 Times Electrical Conductivity of Copper, Diamond-Like Thermal Conductivity

Material Expected to Revolutionize Electronics, Electrical, and Mechanical Fields with High-Performance Direct Circuits

Major Achievement Confirming the Possibility of Mass Production of Perfect Single-Crystal Graphene with Superior Performance

[Asia Economy Reporter Kim Bong-su] Domestic researchers have succeeded for the first time in the world in producing 'graphene' with a perfect structure on a large scale. Graphene is a metamaterial (a material created by humans to have properties not found in nature) that is attracting attention as a next-generation material. It has very high strength and excellent thermal and electrical conductivity, and if mass-produced, it is expected to cause a 'material revolution' in electronics and mechanical fields such as high-performance direct circuits.

The Institute for Basic Science (IBS) announced on the 25th that the research team led by Rodney Ruoff, head of the Multidimensional Carbon Materials Research Division, succeeded for the first time in the world in producing large-area perfect single-crystal graphene without folds or stacking. The research results were published on the 26th in the prestigious international journal Nature (IF 49.962).

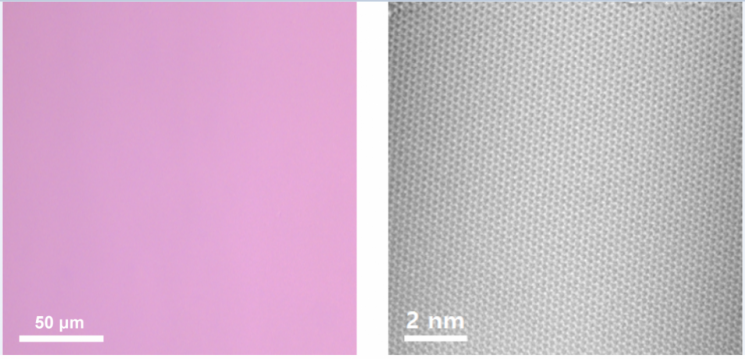

Graphene is a two-dimensional material in which carbon atoms are arranged hexagonally like a honeycomb. It is thin, transparent, and highly elastic, but it is more than 200 times stronger than steel, has electron mobility more than 100 times faster than copper, and has high thermal conductivity similar to diamond, making it notable for its excellent physical properties.

However, previous studies have shown that there were 'stacking regions' where multiple layers of graphene overlapped and 'folded parts' that were wrinkled, and such stacking or folding reduced the mechanical and electrical properties of graphene. The research team also produced stacking-free graphene in 2019 but did not solve the folding problem. They identified that carbon impurities contained in commercially available copper foil used as a substrate for graphene production caused stacking in graphene and succeeded in producing large-area graphene without stacking regions. That research was also published in the international journal Advanced Materials.

In this study, the team focused on the fact that folding occurs during the cooling process after graphene growth and investigated the temperature at which folding occurs, resulting in the successful production of 'defect-free graphene.' Typically, graphene is synthesized at high temperatures above 1320K (1046.85℃) and then cooled to room temperature, but it was confirmed that folding forms at temperatures above 1030K (756.85℃). Therefore, by growing graphene at low temperatures below 1030K (756.85℃) to prevent folding, they synthesized perfect 'defect-free graphene' without folding or stacking even after the cooling process.

Utilizing these research results makes it possible to produce large-area perfect single-crystal graphene without folding or stacking, enabling the manufacture of high-performance integrated circuits that always deliver the same efficiency regardless of the material's position or orientation. The charge mobility of defect-free graphene was 6,000 to 8,000 cm²/Vs, which is seven times higher than silicon and about three times higher than conventional graphene. Higher charge mobility means higher performance with less power consumption. The possibility of mass production was also demonstrated. Using copper-nickel (Cu-Ni(111)) foil as a substrate, they succeeded in simultaneously producing five sheets of defect-free graphene measuring 4×7 cm². Additionally, even after reusing the foil five times, the weight loss was only 0.0001g, indicating that the foil can be reused indefinitely.

The research team explained, "If 'defect-free graphene' is stacked with other two-dimensional materials, it will be possible to develop devices with astonishing performance that have not been developed before," adding, "This opens the way to utilize graphene with excellent performance in various fields such as electronics, photonics, and mechanics."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.