Suggesting the Potential of Next-Generation Flexible Smart Devices with Freeform Shapes

Samsung Electronics, 'Galaxy Z Fold3' · 'Galaxy Z Flip3'. Reference photo. Not directly related to the article. [Image source=Yonhap News]

Samsung Electronics, 'Galaxy Z Fold3' · 'Galaxy Z Flip3'. Reference photo. Not directly related to the article. [Image source=Yonhap News]

[Asia Economy Reporter Kim Bong-su] Amid the rising popularity of foldable smart devices such as flip and foldable phones, Korean researchers have developed the world's first fully foldable transistor, a core material.

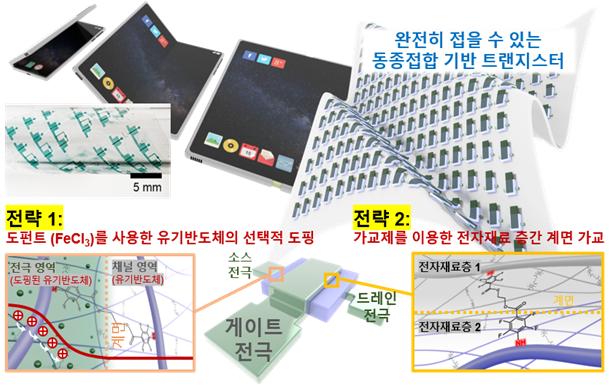

On the 20th, a joint research team led by Professor Jo Jeong-oh of Yonsei University and Professor Woo Han-young of Korea University announced that they have newly developed a fully foldable transistor, a key component of flexible smart devices. The team created the world's first homojunction flexible transistor using conductive polymers based on selective doping methods and crosslinkers. Ultimately, this suggests the possibility of developing next-generation flexible smart devices such as displays, sensors, and semiconductor devices that can bend, fold, and freely change shape.

With the recent increase in demand for foldable smart devices like foldable smartphones, the need for flexible electronic components has become prominent. Flexible smart devices require very high mechanical stability, making the development of electronic materials that can withstand extreme mechanical stability crucial. However, existing metal electrodes, despite their excellent conductivity, are brittle and thus difficult to apply to flexible smart devices that need to bend or fold.

In response, researchers worldwide have conducted studies to apply conductive polymers with mechanical flexibility as semiconductor and electrode materials for flexible smart devices. However, most have failed to achieve the mechanical stability required for flexible smart devices. This is because heterojunctions between electronic material layers (electrodes, semiconductors, insulators) cause interfacial delamination when subjected to extreme physical deformation.

The joint research team introduced crosslinkers and selective doping technology to improve the mechanical stability of polymer thin-film transistors. First, the crosslinking method for electronic materials through crosslinkers enhances interfacial adhesion between each electronic material layer, improving the low interfacial adhesion occurring in heterojunctions and preventing damage caused by heat or chemical processes during transistor fabrication.

Additionally, by introducing selective doping, the team eliminated the heterojunction between electrode and semiconductor layers where interfacial delamination occurs and formed a homojunction interface, further enhancing the mechanical stability of polymer transistors. The transistors produced through this research exhibited excellent mechanical stability, maintaining electrical characteristics even at extreme curvature radii.

The research team solved the critical issues of interfacial delamination and damage, which are important for the development of flexible smart devices, through various electronic materials, interlayer interface crosslinking, and selective doping methods. This presents a new direction for future research on semiconductor devices applicable to flexible smart devices.

Professor Jo Jeong-ho explained, "This research solved the critical issues of heterojunction interfacial delamination and damage in flexible semiconductor device fabrication," adding, "It presents technology for producing fully foldable semiconductor devices, not just simple flexible semiconductor devices."

The research results were published on the 18th in the international academic journal Science Advances.

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

!["The Woman Who Threw Herself into the Water Clutching a Stolen Dior Bag"...A Grotesque Success Story That Shakes the Korean Psyche [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)