ThermoLab Korea's 'Smart Packaging'... Reusable Over 100 Times

Electronic Invoice Display on Box Top... Achieves 100% 'Paperless'

Location Tracking and Temperature Control Available... "Packaging Paradigm Will Change"

[Asia Economy Reporter Lee Junhyung] The key keyword in this year's fresh food packaging market is 'eco-friendly.' E-commerce companies have been actively seeking reusable packaging materials since last year. This is because they are suitable for the trending ESG (Environmental, Social, and Governance) management and are expected to reduce costs in the long term.

Thermolab Korea has recently emerged as a 'rookie' in the packaging market. The company established itself in the industry by supplying eco-friendly packaging materials to Market Kurly in 2017. In 2019, it developed and supplied the reusable packaging material 'Fresh Bag' used for fresh food delivery by Coupang. It is currently engaged in technology development and cooperation discussions with major e-commerce companies such as Shinsegae SSG.com and TMON.

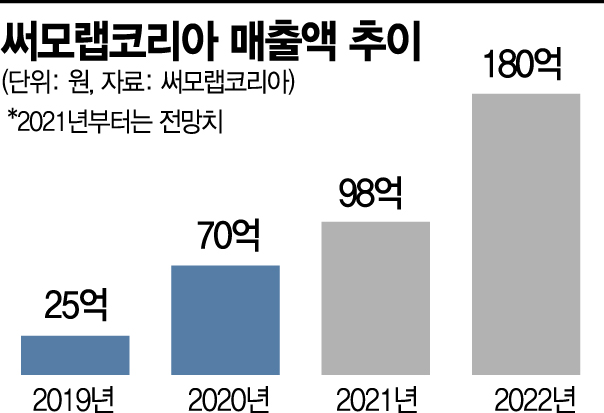

The company has greatly benefited from the COVID-19 pandemic. As the so-called 'homebody' population increased and competition in fresh food delivery in the e-commerce industry intensified, the demand for packaging materials that can maintain freshness during transportation also increased. The company's sales last year reached 7 billion KRW, nearly tripling compared to the previous year (about 2.5 billion KRW).

Last year, the packaging market itself grew rapidly, which also benefited the company. According to Statistics Korea and others, the domestic fresh food packaging market last year was worth 2.17 trillion KRW, an increase of 840 billion KRW from the previous year (1.33 trillion KRW). This is why the company is focusing on developing smart packaging materials. Choi Seok, CEO of Thermolab Korea, said, "There is not much technological difference in delivery boxes among companies," adding, "I thought that developing competitive new products was necessary to properly scale up."

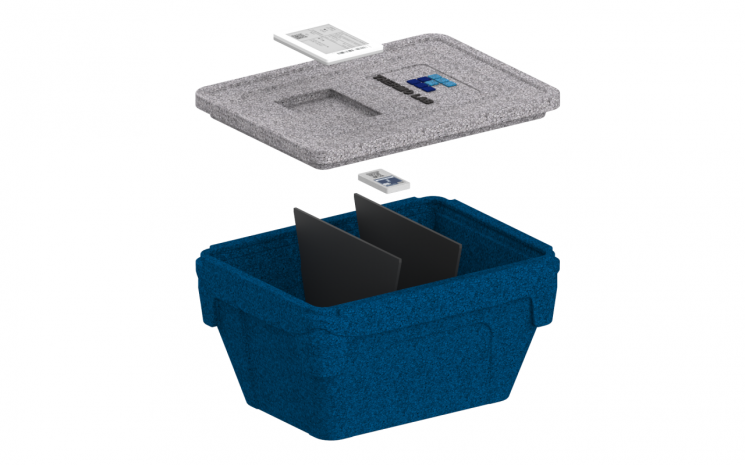

The prototype development is already in its final stages. The smart packaging material developed by the company is a 5th generation packaging material capable of location tracking and temperature control through sensors such as data loggers. According to CEO Choi, the packaging market has evolved in the order of '1st generation non-eco-friendly - 2nd generation partially eco-friendly - 3rd generation recyclable - 4th generation reusable - 5th generation sustainable.' Currently, the domestic packaging market mainly consists of 3rd and 4th generation products. CEO Choi said, "In advanced countries such as the U.S. and Europe, the spread of smart packaging materials integrated with information and communication technology (ICT) is already expanding," adding, "Due to environmental issues and problems with the supply of disposable packaging materials, the packaging paradigm will change soon."

The core of smart packaging is durability. The manufacturing cost of smart packaging is 300,000 to 400,000 KRW per unit, so it must be reused at least 100 times to achieve cost reduction effects. The company used eco-friendly cushioning material expanded polypropylene (EPP) from the German chemical company BASF to make the packaging withstand loads of up to 500 kg. EPP is composed of 98% air, making it eco-friendly, and it is durable enough to be used as automotive interior material.

The electronic invoice of smart packaging developed by Thermolab Korea. It realized a 'paperless' invoice with a digital ink display.

The electronic invoice of smart packaging developed by Thermolab Korea. It realized a 'paperless' invoice with a digital ink display. Photo by Lee Junhyung

The digital invoice using electronic ink is another key point. CEO Choi attached an electronic ink display to the top of the packaging, inspired by the fact that numerous paper invoices are discarded during the delivery process. He explained, "We are implementing paperless transportation with digital invoices," adding, "We conducted drop tests and designed it with IP56 dust and water resistance to prevent malfunctions in the logistics environment, which inevitably involves many shocks."

The company also plans to enter the pharmaceutical logistics market. CEO Choi said, "Pharmaceuticals have high unit prices, so if there are problems maintaining temperature during transportation, the losses are significant," adding, "In the bio market, where companies are willing to invest in high-quality cold chains, the demand for smart packaging materials is considerable."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.