2017 Government Project Awarded: Fuel Efficiency Improvement and Carbon Dioxide Emission Reduction

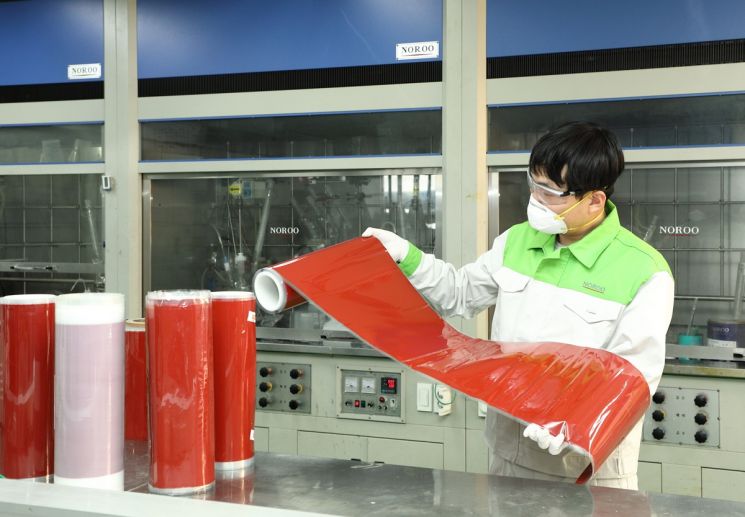

A researcher at Noroo Paint Research Institute inspecting an anti-fouling film.

A researcher at Noroo Paint Research Institute inspecting an anti-fouling film. [Photo by Noroo Paint]

[Asia Economy Reporter Kim Jonghwa] Noroo Paint announced on the 12th that it has secured and is developing a project titled "Development of Low-Friction Film Technology with Antifouling Performance for Greenhouse Gas Reduction in Ships," one of the industrial core technology development projects led by the Ministry of Trade, Industry and Energy. The company also filed a patent application last December related to "Modified Ether Polydialkylsiloxane Compounds, Their Manufacturing Methods, and Marine Antifouling Coatings Containing Them."

The Noroo Paint Research Institute was selected in 2017 for a new government project worth a total of 6 billion KRW through industry-academia-research cooperation. As a result of about four years of research and development, it filed a patent related to new materials for ship antifouling films. The research team plans to complete the development of eco-friendly ESG (Environmental, Social, and Governance) antifouling film technology for the shipbuilding industry by the end of this year.

Recently, as ESG management has become a global issue and regulations on reducing greenhouse gas emissions from ships have been significantly strengthened, interest in this technology is increasing. Currently, antifouling coatings are used to prevent underwater organisms such as barnacles, oysters, and seaweed from attaching to the submerged surfaces of ships. However, some antifouling coatings gradually dissolve and release coating films underwater, contributing to marine pollution.

The Noroo Paint Research Institute is developing antifouling film technology that can prevent this phenomenon by solving the problems of atmospheric and marine pollution caused by conventional spray-type antifouling coatings and their complex coating processes. This technology achieves seawater resistance and low-friction performance, improving ship fuel efficiency and reducing greenhouse gas emissions.

This technology consists of a complex system related to "low-friction antifouling silicone coating materials and film surface control and treatment." It removes VOCs (volatile organic compounds) generated from scattering during the ship coating process and simplifies the coating process, thereby enhancing productivity.

In the future, the ship coating market is expected to see intense competition in value-creating eco-friendly technologies and coatings. Film-type antifouling coatings provide shipowners with improved fuel efficiency and reduced greenhouse gas emissions, while shipbuilders benefit from increased productivity and safety. Additionally, it minimizes organic compound emissions, making it environmentally superior.

Noroo Paint plans to further develop this technology to secure competitiveness as a low-carbon, energy-saving new material component necessary for climate change response. Through this, the company aims to break away from dependence on advanced foreign technologies in Korea’s key industries such as shipbuilding and related chemical products and is working closely with the government to introduce eco-friendly ESG technologies.

A Noroo Paint official stated, "We are conducting research to localize the core technology of film-type antifouling coatings for the domestic shipbuilding and coating industries, with completion expected by the end of this year." He added, "We expect effects such as fuel savings and reduced carbon dioxide emissions from technology application, as well as the establishment of an eco-friendly ESG workplace without coating scattering compared to conventional spray coating methods."

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.