24/7 Operable Autonomous Driverless Forklifts and AGVs Based on 5G MEC Enhance Work Efficiency

Providing Centimeter-Level Ultra-Precise Positioning with 5G RTK-GPS at Ports Applied to Digital Twin

(From left) Jae-yong Seo, Executive Director of Smart Infrastructure Business at LG Uplus; Chang-hoon Kim, CEO of BIDC; Bu-geun Jo, CEO of Russell Robotics.

(From left) Jae-yong Seo, Executive Director of Smart Infrastructure Business at LG Uplus; Chang-hoon Kim, CEO of BIDC; Bu-geun Jo, CEO of Russell Robotics.

[Asia Economy Reporter Eunmo Koo] LG Uplus will apply automated logistics equipment and ultra-precise location information solutions based on 5G at Busan New Port.

LG Uplus announced on the 29th that it has signed a business agreement for cooperation in automated logistics operations by applying autonomous three-way unmanned forklifts and Automated Guided Vehicles (AGVs) at the BIIDC logistics warehouse in the Busan New Port hinterland complex, together with BIIDC, a logistics company affiliated with Dongwon Group, and Russell Robotics, a logistics automation specialist.

The three-way unmanned forklifts and AGVs based on 5G and Mobile Edge Computing (MEC), which LG Uplus will apply for the first time in Korea, are expected to improve operational efficiency by rearranging goods inside the warehouse without workers during nighttime or idle hours. These autonomous logistics devices automatically verify processed goods and automate inbound processing without workers by linking with BIIDC’s Warehouse Management System (WMS).

The three-way unmanned forklift to be introduced by LG Uplus and Russell Robotics at the Busan New Port logistics warehouse can freely move forks to both sides of the aisle without the forklift having to rotate up to 9 meters high even in narrow aisles, thereby maximizing the use of upper shelves and improving work efficiency. In addition, the AGV is an independent device that autonomously determines its location through lasers without fixed landmarks or guide lines and finds its own route between the starting point and destination like a car’s navigation system. It can move safely by recognizing the surrounding environment in any warehouse.

These automated logistics devices will be linked to the Busan MEC Center, currently under construction by LG Uplus, through a 28 GHz 5G network that can transmit large volumes of data with low latency.

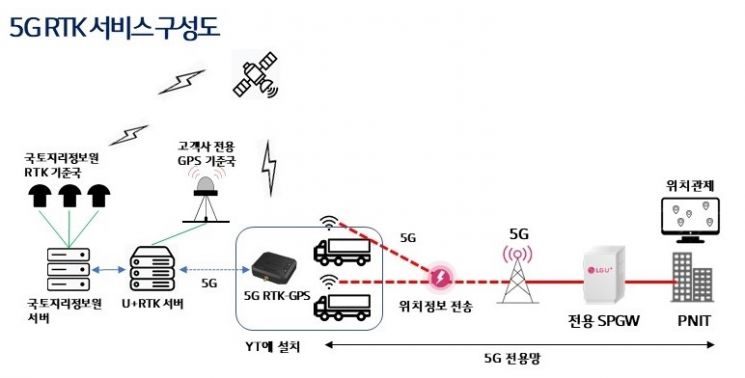

Along with this, LG Uplus will provide a 5G dedicated network and an ultra-precise location information solution (RTK) to be used as basic data for digital twins at Pier 1 of the Busan New Port International Terminal within this year. The 5G RTK-GPS terminal will precisely correct GPS information in real time with the network RTK server via 5G and deliver the corrected location signals to the control room of Pier 1 at Busan New Port International Terminal. This will enable precise real-time tracking of yard tractors and other equipment to improve operational efficiency and can be used as basic data for digital twins.

The 5G RTK-GPS terminal will be configured as a single device providing both 5G communication and ultra-precise location solutions, supporting outdoor equipment use in both winter and summer. This 5G RTK-GPS will be installed on quay cranes that load and unload containers from ships, yard tractors that transport containers, and forklifts (reach stackers and empty handlers) that move containers in the yard, helping ensure safe and efficient operations.

Having previously established a 5G remote-controlled yard crane at Gamman Pier in Busan Port, LG Uplus plans to solidify its position as a leader in domestic automated ports by providing automated logistics warehouses and digital twin-based ultra-precise location information solutions at Busan New Port. Jae-yong Seo, Executive Director of LG Uplus Smart Infrastructure Business, said, “By providing logistics equipment automation and ultra-precise location information solutions based on 5G MEC at Busan New Port warehouses and piers, we will supply information to be used in digital twins and strive to pioneer the market by discovering various services in the 5G smart port market in the future.”

© The Asia Business Daily(www.asiae.co.kr). All rights reserved.

![A Woman Who Jumps Holding a Stolen Dior Bag... The Mind-Shaking, Bizarre Con of a "Human Knockoff" [Slate]](https://cwcontent.asiae.co.kr/asiaresize/183/2026021902243444107_1771435474.jpg)